Tank Cleaning Nozzles (Part 2)|How to Select Right Nozzle Based on Tank Size

Table of Contents

IKEUCHI’s tank cleaning nozzles automate and shorten the cleaning process for the interior of tanks, containers, and vessels. They are among the most recommended nozzles of IKEUCHI’s wide range of products. Meanwhile there is still the question of which tank cleaning nozzle is the right one.

This series of articles is meant to introduce the different nozzles and show their specific functions in order to help decide which nozzle is the best fit for your application or need.

This first article will be an introduction to the types of tank cleaning nozzles, their features and applications.

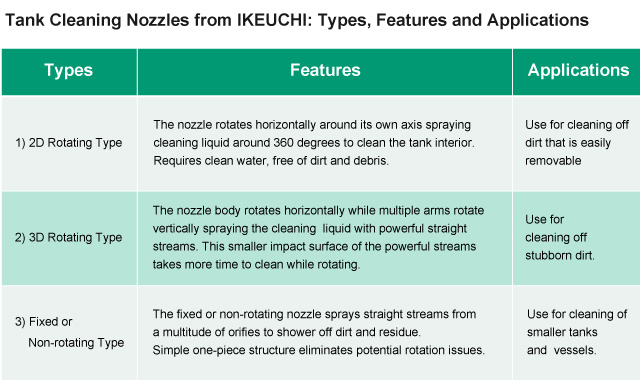

Tank cleaning nozzles are classified into three types.

Even though each of these three types of nozzles can clean the inside of a tank completely, using the one best suited for the specific tank and residue ensures a more effective and efficient cleaning process.

The first one, a 2D rotating nozzle, is best suited to rinse off dirt or residue that is easily removable.

Next, the 3D rotating type, sprays a powerful straight stream of cleaning liquid and is suited to remove stubborn dirt and residue.

Lastly, the fixed or non-rotating type nozzle, is ball shaped which makes it possible to spray a multitude of streams at every angle to clean off dirt and residue in smaller tanks or vessels.

The following is a closer look at each of the nozzle types, their features, structure, and spray operation.

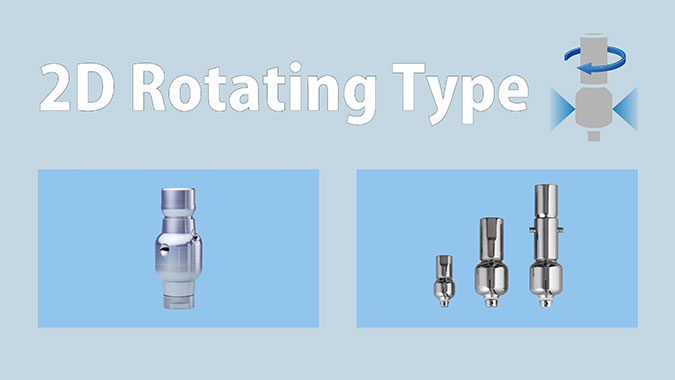

First a look at the 2D rotating type. Our ES Series and SR Series belong to this category.

These nozzles are suited for rinsing off dirt that is easily removable.

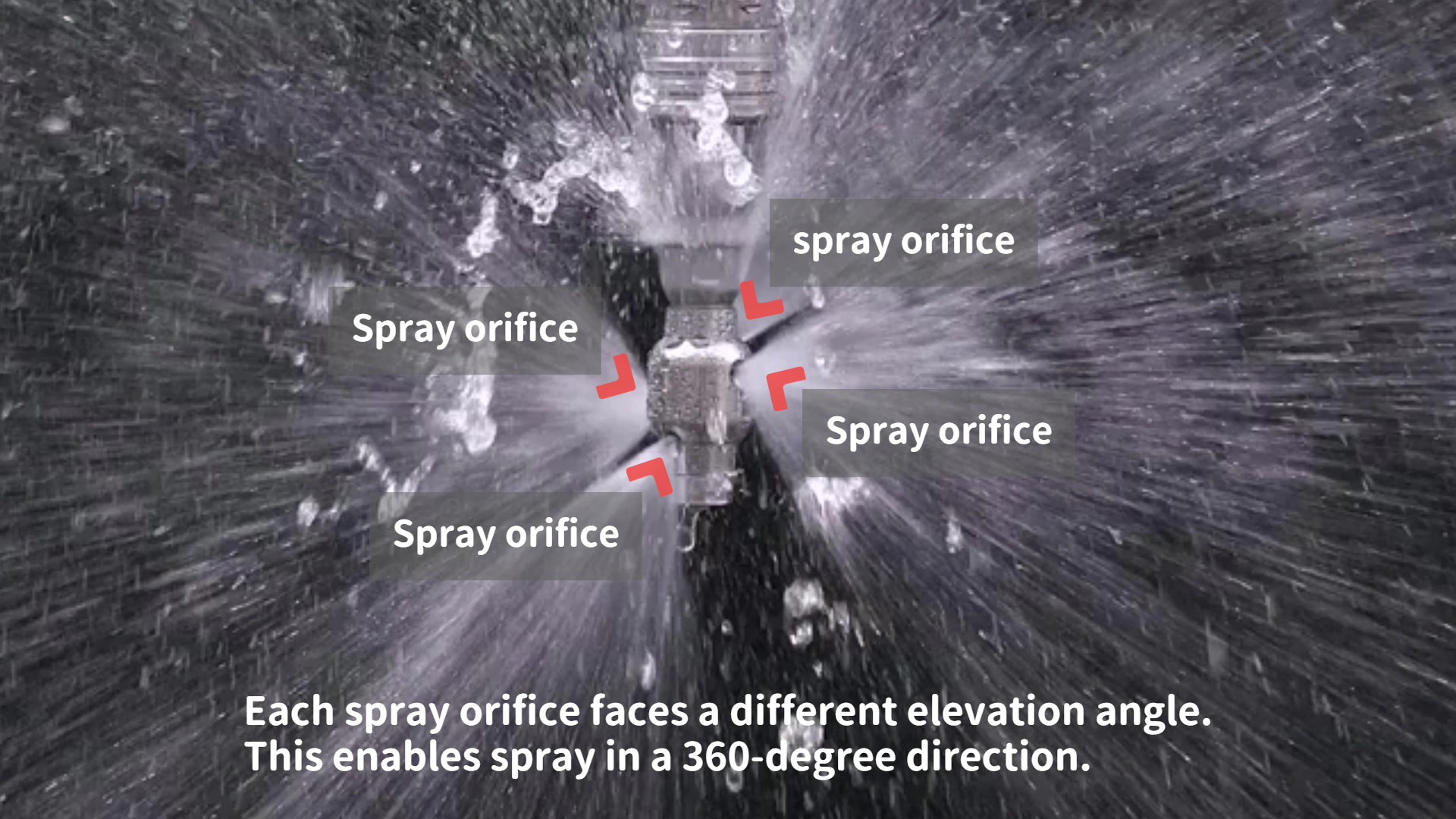

The 2D rotating nozzle body rotates horizontally and the nozzles spray a cleaning liquid ensuring 360 degree coverage.

The rotating nozzle body has multiple spray orifices for spraying the cleaning liquid at different angles. This way the entire interior of a tank can be cleaned while the nozzle body only rotates horizontally. The rotation is entirely fluid-driven, not requiring a power supply or compressed air. Installation of these nozzles is very easy. Besides it is easy to install the nozzles.

Debris and foreign particles in the water can cause problems. If debris gets into the nozzle, it can cause unstable rotation or even complete stoppage. Make sure to install a strainer at the liquid inlet of the nozzle to prevent debris from entering.

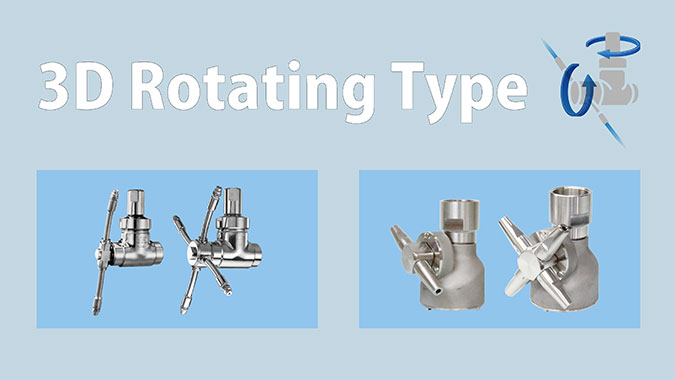

Next a look at the 3D rotating type. JA (Jet Attacker) Series and RJ (Rotary Jetter) Series belong to this category.

The 3D rotating nozzle is used for powerful cleaning of the tank interior. The nozzle body rotates horizontally around its own axis, while a disk with multiple nozzle arms attached to the body rotates vertically spraying straight streams of cleaning liquid. The combined motion of body and arms, horizontal and vertical, makes it possible to spray powerful streams ensuring the three-dimensional cleaning of the tank.

This combination produces very powerful liquid straight streams, which take some time to completely clean the entire interior of a tank because of the smaller surface covered by each powerful stream. These powerful straight streams of the 3D type make it uniquely suitable for sticky, stubborn dirt on interior walls.

Please note that the larger number of moving parts for the rotating mechanism require more maintenance than the simpler 2D type. Debris and foreign particles in the water can cause problems. If debris gets into the nozzle, it can cause unstable rotation or even complete stoppage. Make sure to install a strainer at the liquid inlet of the nozzle to prevent debris from entering.

The third option is the fixed or non-rotating type. These fixed nozzles have no moving parts.

Both of the above-described nozzles, the 2D and 3D nozzle, clean by rotating. The most common problem with these nozzles is an issue with the rotation. While installing a strainer in the piping system is essential and will prevent most foreign particles from causing problems in the nozzles, it is not guaranteed to eliminate the problem completely.

This fixed type nozzle on the other hand is constructed to spray straight water streams from a multitude of orifices, like a shower, to clean the interior of a tank. This simple one-piece structure is easy to maintain and eliminates any issues regarding rotation.

However, as shown in the image below, the distance between the straight streams increases the further away from the orifice they get, resulting in growing gaps that remain uncleaned. For that reason the fixed type tank cleaning nozzle is best suited for smaller tanks and vessels.

The above offered an introduction to the three types of tank cleaning nozzles, their features, and applications. The table below gives a brief summary for your convenience.

This article was a very basic introduction to tank cleaning nozzles with much more to consider when selecting the right nozzle for your specific application. Follow us for more articles.