Energy, Ceramics and Waste Disposal

- HOME

- Products Overview

- Energy, Ceramics and Waste Disposal

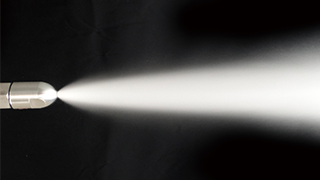

Atomization technologies play a crucial role in fostering a circular economy by facilitating stable electricity supply during summer,

mitigating peak demand, and promoting effective utilization of waste.

-

Gas Cooling and Flue Gas Treatment

Flue gas cooling nozzles designed to prevent dioxin formation in waste incineration facilities. Denitrification nozzles effectively remove NOx from flue gas, while desulfurization nozzles target the removal of SOx.

-

Sewage Combustion

For spraying sewage or wastewater, we offer a lineup of spray nozzles with clog-resistant designs capable of spraying liquids containing foreign particles.

-

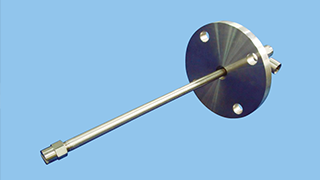

Gas Turbine Inlet Air Cooling

By utilizing the heat of vaporization during fog evaporation, our system cools the inlet air taken into the duct, enhancing its density and consequently recovering the diminished power output. Additionally, this system minimizes the discharge of unvaporized water.

-

Air Fin Cooler Assist Cooling

Spraying water evenly over the heat transfer surface of an air fin cooler significantly conserves water compared to traditional sprinkler systems.

Additionally, the system can be installed while facilities are in operation. -

Kiln Cooling

Cooling the steel shell of a rotary kiln (inner-heated type) by spraying fine fog extends the mean time between repairs for refractories. Additionally, the system minimizes waste water discharge, thereby preventing contamination of the surrounding environment.

-

Dust Suppression and Dust Control

We provide dust control solutions for conveyor hoppers and transfer points. Dust particles adhere to fine fog droplets, settling onto the ground. Additionally, the system can spray a deodorant to reduce foul odors.