Drying and Air Blow-off

- HOME

- Products Overview

- Drying and Air Blow-off

Addressing manufacturing site challenges begins with optimizing air usage.

We propose switching to dedicated air nozzles to enhance productivity and product quality, reduce costs, lower noise levels, and resolve other operational issues.

-

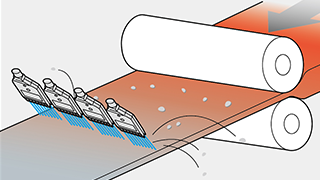

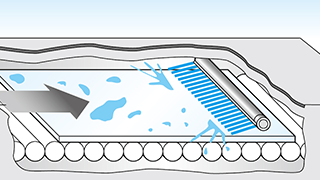

Blow-off and Drying

Blowing off water from surfaces of products after filling or washing processes in the manufacturing of bottled beverages or packaged food helps ensure cleanliness. Additionally, preventing dust or particle adhesion eliminates print failures such as feathering, enhancing product quality.

-

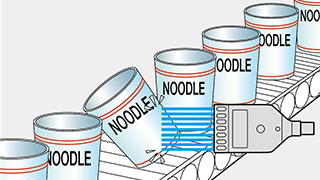

Sorting and Rejection of Defective Products

Air blowing is used to sort products flowing on a line into Class A, Class B, Out of Specification, and Defective categories, while also removing foreign objects from the line.

-

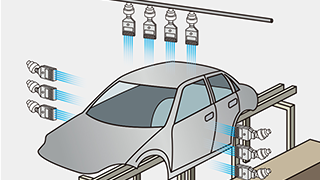

Air Blowing for Surface Treatment Prior to Painting

Before painting, blowing air helps reduce paint defects by removing foreign particles and dust adhered to products, as well as by blowing off water drops remaining after washing.

-

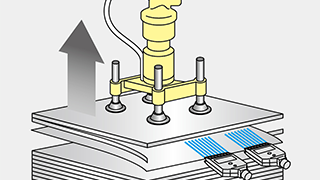

Prevention of Double Sheet Feeding (Detachment)

To prevent double sheet feeding during vacuum conveying, complete detachment is ensured by blowing air towards the gaps between each workpiece, such as thin metal sheets.

-

Pinpoint Cooling of Molded Products

Cooling products that exit an electrodeposition dry-off oven is essential. Sufficient cooling not only dries the coating on products but also reduces color migration.

-

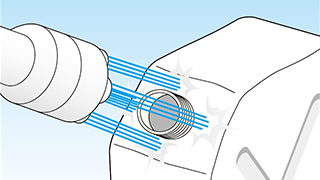

Installation Inside Equipment

Our lineup features a diverse range of air nozzles, including compact types and long flat types with thin nozzle tips. These options can be easily mounted inside equipment or in narrow spaces.