Quality Assurance

Initiatives for Quality Assurance

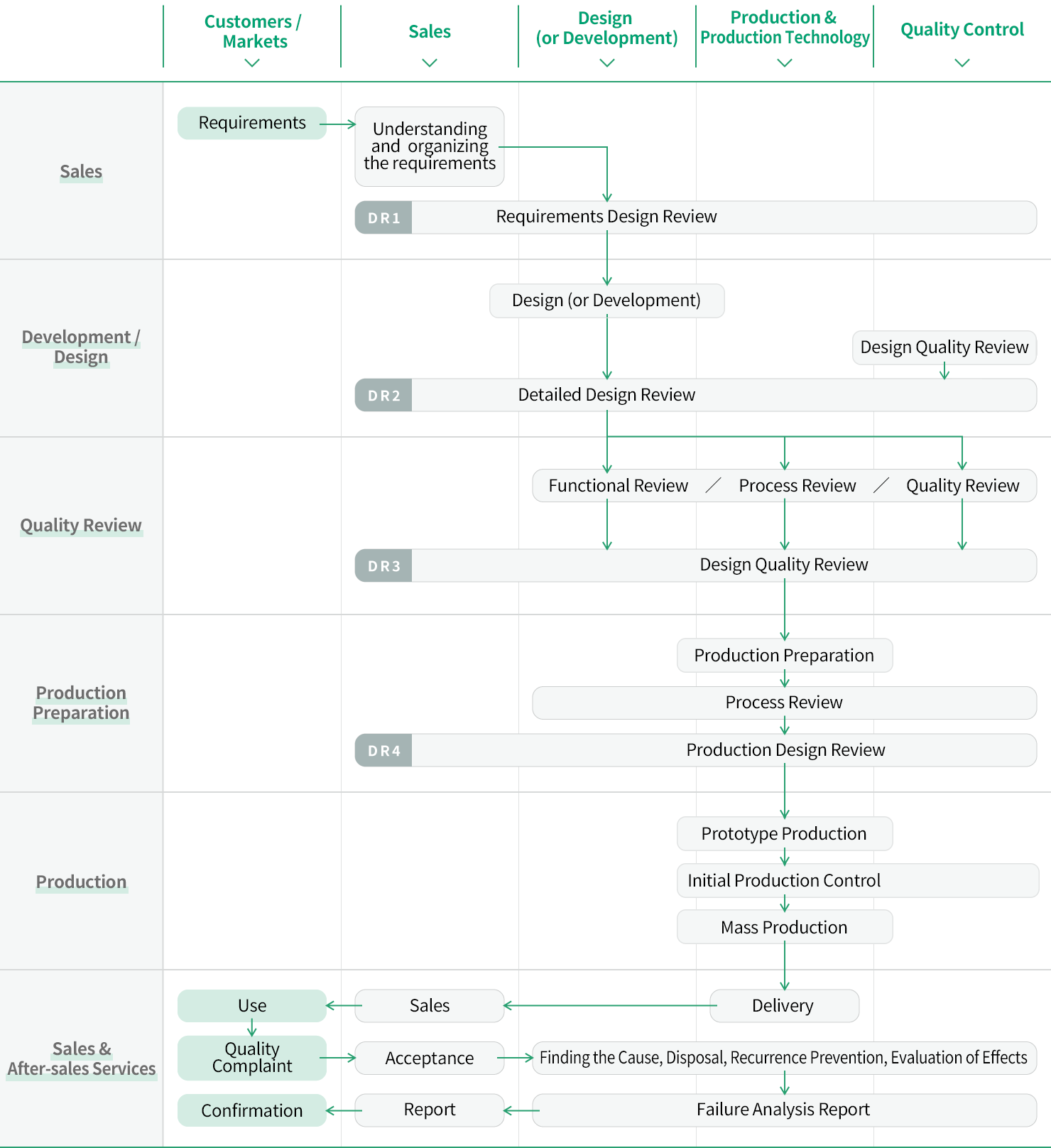

At Ikeuchi, we have established an integrated system between our sales and manufacturing departments to fulfill customer requirements and market needs. In the event of any quality issues, we aim to provide our customers with satisfactory responses by conducting thorough investigations into the root causes, implementing appropriate countermeasures, and reporting the results.

Quality Assurance System Diagram

Introducing Our Production Facilities

Our production facilities are located in four different places. At the Kure Factory, equipped with state-of-the-art machinery, we manufacture ceramic spray nozzles, while skilled engineers at the Nishiwaki Hori Factory produce metal spray nozzles that are challenging to manufacture. At our Kamihie Factory in Nishiwaki City, these spray nozzles are combined with IoT devices and driving mechanisms to manufacture solution systems. Additionally, at our Hanoi Factory in Vietnam, we produce versatile spray nozzles; through collaborative efforts between these factories, we offer competitive products in the market.

Kure Factory

Development and manufacturing of ceramic and plastic spray nozzles

We develop and manufacture spray nozzles made from ceramic materials with high hardness, which undergo unique shrinkage and deformation during firing, as well as mass-produced plastic spray nozzles. Through years of accumulated expertise, our commitment to “own-process completion,” which is based on ISO principles and encapsulated in the philosophy “the next process is your customer,” along with the implementation of our proprietary inspection systems, we ensure the consistent production of high-quality, high-precision products in large quantities.

Nishiwaki Hori Factory

Development and manufacturing of metal spray nozzles

The spray nozzles we manufacture come in a wide variety, ranging from customized one-of-a-kind items to large-scale mass production. We work with materials not only limited to stainless steel and plastic but also with difficult-to-machine materials such as Hastelloy and titanium. To materialize our customers’ diverse needs, we perform processing with tolerances down to a micrometer level, achieving an almost 100% yield rate.

Nishiwaki Kamihie Factory

Development and production of applied products incorporating spray nozzles

We develop various system solutions for applications such as humidification, cooling, and landscaping. Offering a wide variety of products including pump units, fluid control equipment, and control boards, we strive to ensure quality using analysis methods such as FMEA, as well as state-of-the-art inspection facilities and equipment. Aligning with the theme of “Providing peace of mind to our customers,” we prioritize creating an environment where all the members involved in manufacturing can learn and grow effectively.

Hanoi Factory (IKEUCHI VIETNAM CO., LTD.)

Manufacturing of stainless steel spray nozzles

To speedily supply spray nozzles with consistent quality worldwide, we have built an integrated production system from material procurement to product completion. In addition, while primarily undertaking mass production of stainless steel spray nozzles, we ensure the same levels of quality and precision as our factories in Japan. Efforts are also dedicated to introducing cutting-edge machining equipment and inspection devices, as well as to developing our human resources, ensuring that our factory becomes capable of promptly responding to global needs.

Diverse Facilities Upholding Quality

The diverse facilities upholding our quality is the keystone to ensure the reliability and high-quality of our products. This includes measurement devices to assess spray nozzle performance characteristics such as spray droplet sizes, flow rates, and distributions, as well as inspection rooms for evaluating the durability and standards compliance of our solution systems. We operate a wide range of equipment and facilities to deliver products that earn our customers’ trust and peace of mind.

Electrical Inspection Room

A dedicated inspection room for equipment, including sensors and controllers for temperature and humidity control.

Space Humidification and Cooling Experiment Room

An area for evaluating the effects of humidification and cooling in large spaces.

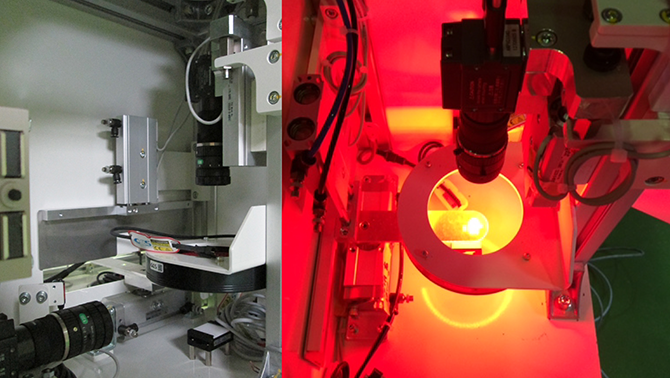

Image Inspection Devices

For products manufactured in large quantities, we use cameras to visually inspect crucial points to guarantee the quality of spray performance.

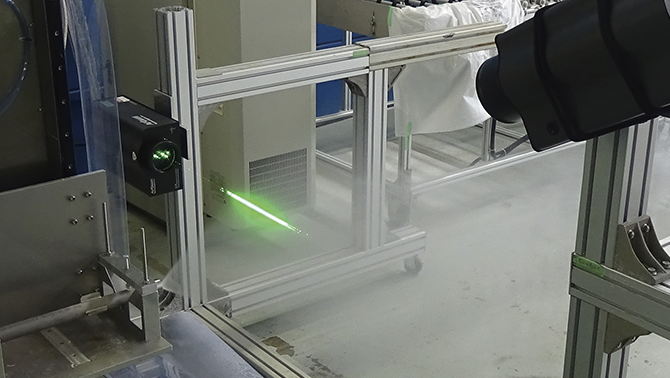

Measurement Instruments for Spray Droplet Diameters

We utilize various measurement instruments such as the Fraunhofer diffraction method, laser Doppler method, and shadowgraph method to measure the spray velocity and droplet diameters during spraying, enabling us to fulfill a wide variety of customer requirements.

Spray Impact Measuring Device

This device measures the strength upon impact of sprayed liquid or gas with a target object. By outputting the impact force as a waveform, we ensure alignment with customer specifications.

Spray Distribution Measuring Device

This device automatically measures the distribution of sprayed volume in the width direction using image analysis software. Since the spray distribution varies depending on the spray height and pressure, it enables customers to evaluate the performance of spray nozzles under specific conditions.