Pulp, Paper, and Printing

- HOME

- Products Overview

- Pulp, Paper, and Printing

We provide products that enhance productivity and product quality across various applications.

These include canvas cleaning, trimming, moisture content conditioning, and implementing countermeasures against paper sticking in forwarding or feeding sections, as well as against static electricity.

-

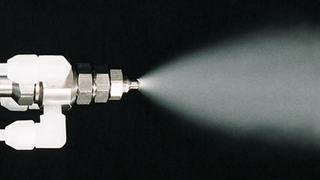

Trimming

A high-impact, extra-fine solid stream jet not only produces a beautiful cross-section but also minimizes nozzle clogging due to paper dust adhesion. Thanks to its ultra-hard ceramic orifice, the nozzle maintains stable performance over an extended period.

-

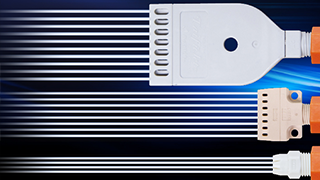

Canvas Cleaning and Tank Cleaning

We offer a lineup of nozzles specifically designed to resist recirculated water, ideal for use with shower pipes in paper machines or their headers. These nozzles excel in cleaning canvases in drying and coating sections, as well as other components used in the papermaking process.

-

Paper and Cardboard Moisture Conditioning

Our systems are specifically designed for moisture conditioning and moisture content control, aiming to decrease defect rates. These systems effectively prevent issues like up warps, down warps, and cracking along score lines, while also ensuring the avoidance of excess adhesive application. Additionally, the flow rate can be adjusted to suit the specific paper type and line speed requirements, ensuring optimal performance.

-

Drying and Air Blowing

These systems are versatile, serving as air curtains to block dust and particles from entering facilities, as well as for blowing off in a couch pit on papermaking machines. They are also effective in preventing paper sticking at feeder or delivery parts.

-

Coating

Our lineup includes clog-resistant nozzles and anti-dripping nozzles, ensuring an even coating with fine droplets of atomized adhesives, anti-slip agents, or starches.

-

Solutions to Static Electricity and Humidification

We offer Dry Fog humidification to effectively control humidity in printing processes to prevent various problems, such as brief machine stops, ink striation from a doctor, feathering due to static electricity, feeder paper jams, folding failures, and fire hazards from ignition.