Electronics

- HOME

- Products Overview

- Electronics

Manufacturing plants for increasingly compact and highly functional electronic devices benefit from enhanced product yield through the use of high-precision spray nozzles and Dry Fog humidification.

-

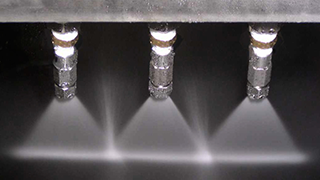

For Precision Cleaning Wet Processes

For semiconductor wafer cleaning, precision cleaning of printed circuit boards, and DI water rinsing in wet processes. Applications also include development, etching, stripping, slurry dispensing, and film coating.

-

Static Electricity Prevention and Dry Fog Humidification

Solutions for challenges such as electrostatic discharge destruction and dust adhesion that static eliminators (ionizers) alone cannot address. These include reducing pick and place errors, lowering failure rates, and maintaining optimal humidity in cleanrooms.

-

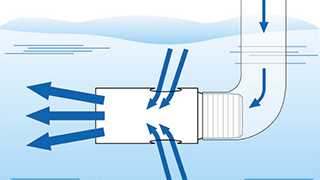

Immersion Cleaning and Liquid Agitation

With their compact and lightweight design, ejector nozzles deliver excellent performance across various applications. These include agitating plating solutions, immersing printed circuit boards for cleaning, accelerating etching reactions for submerged products, and agitating solutions in tanks.

-

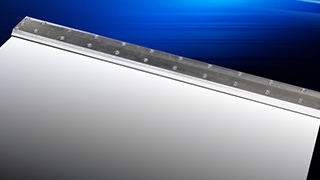

Slit Nozzles Used with Liquid or Air

Slit nozzles produce a thin, laminar flow of liquid or air with consistent thickness across the lateral direction. This design not only reduces costs associated with chemical solutions, DI water, and air but also makes these nozzles suitable for use in smaller, more compact equipment.

-

Blow-off, Drying, and Air Blow

Incorporating a noise-suppressing design, TAIFUJet air nozzles deliver air with an even impact distribution, making them ideal for blowing off water from PCB surfaces. This design also helps reduce air consumption.

-

Slit Nozzles Used with Air

Slit nozzles, also known as air knives, blow air with an even distribution, making them ideal for removing water from the surfaces of PCBs or flat panels.