Basics of Spray Nozzles | Classification of Spray Droplet Size

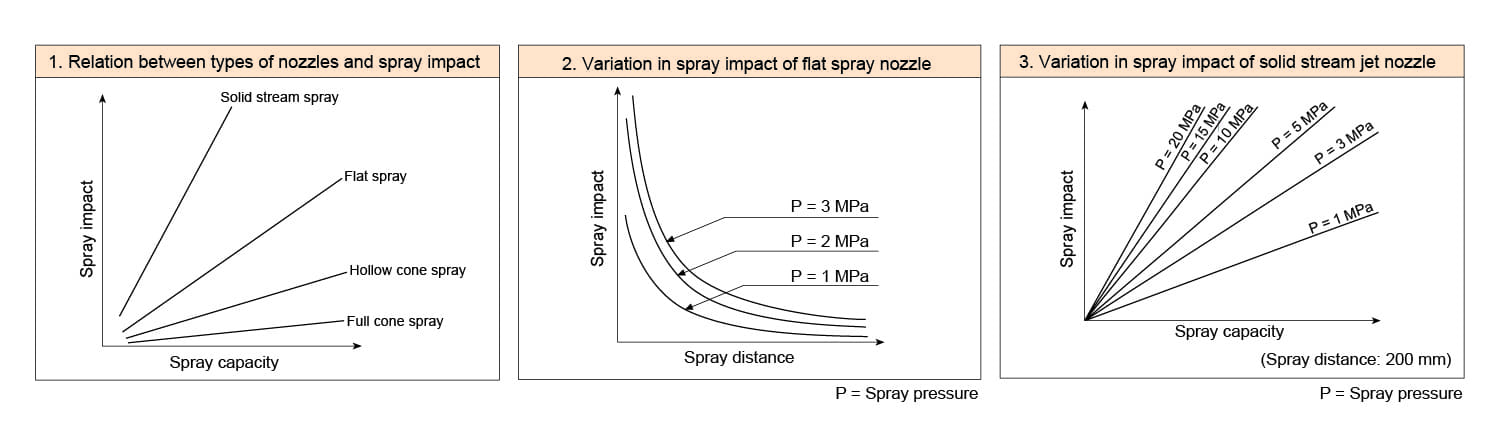

Spray impact describes the force with which the spray droplets hit the target surface.

The stronger the spray impact, the better the cleaning effect.

Solid stream jet nozzles have the strongest spray impact (see Fig. 1). The wider the spray angle and the larger the spray area becomes, the weaker the spray impact.

The spray impact also decreases as the distance between the nozzle and the object increases (see Fig. 2).

Given the same pressure, the larger the spray capacity the nozzle has, the stronger the spray impact and cleaning effect (see Fig. 3).  For further details on spray impact, please refer to our FAQ titled “What is Spray Impact?”

For further details on spray impact, please refer to our FAQ titled “What is Spray Impact?”

It explains how to enhance spray impact with your current nozzle and how to calculate its impact to assist in selecting a new nozzle.

Each nozzle series is carefully designed to withstand specific pressures.

Depending on the operating system, sudden pressure can be three to five times as much as the spray pressure. Consider measures to prevent these sudden pressure increases or surges in water pressure.

For high pressure use, metal nozzles are recommended over plastic nozzles.

In general, as the liquid viscosity increases, the spray capacity and angle decrease, the spray distribution loses uniformity and the droplet size increases. High liquid viscosity increases the resistance inside the pipe supplying the nozzle, causing a drop in the liquid pressure which also needs to be considered.