Technical Library

- HOME

- Technical Library

- Environmental Control for Poultry Houses

Environmental Control for Poultry Houses

Intro

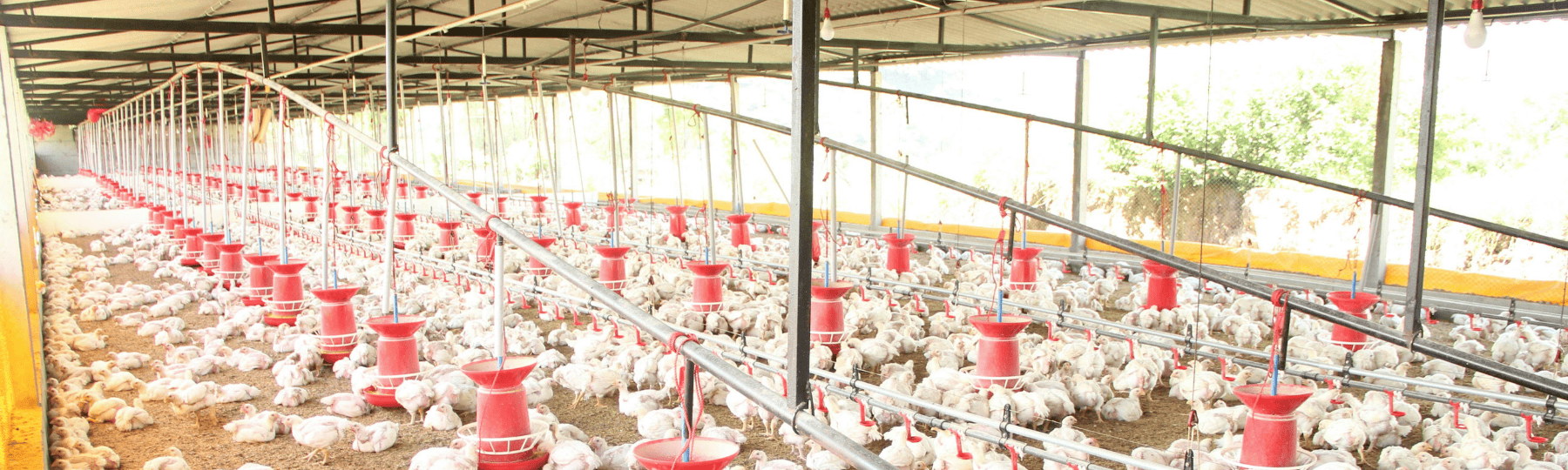

Maintaining optimal environmental conditions in a poultry house is essential for the health and productivity of the flock. Among the various factors that influence poultry farming, temperature control is one of the most critical. Without effective cooling systems, poultry are highly susceptible to heat stress, dehydration, and a range of health issues that can severely impact their well-being and farm profitability. This article explores the risks associated with inadequate cooling in poultry houses and underscores the necessity of investing in proper climate control for successful poultry management.

Common Challenges

Solution: IKEUCHI’s KBN Series Hydraulic Spray Nozzle

IKEUCHI’s KBN Series hydraulic spray nozzle provides an innovative solution for maintaining optimal poultry house conditions. This advanced cooling fog system, equipped with sensor-controlled technology, automatically adjusts temperature and humidity levels based on external air conditions. Each installation is customized to align with the farm’s ventilation style, ensuring maximum efficiency.

Benefits

- Enhanced Hygiene: Reduces the risk of disease and infection.

- Improved Animal Comfort: Creates a stress-free environment, leading to increased productivity in both egg quantity and quality.

- Cooling Without Wetting: Effectively lowers temperatures without causing excessive moisture buildup, preventing stress-related issues in poultry.

Advantages

- Easy Installation: Simple setup tailored to each farm’s ventilation system.

- User-Friendly Control: Automated sensor adjustments provide seamless operation.

Applications

- Direct Cooling Above Poultry: Installation along the ceiling ensures efficient cooling distribution.

- Additional Uses: Humidification, indoor cooling, and outdoor cooling solutions.

Investing in IKEUCHI’s KBN Series ensures a healthier, more productive poultry farm while minimizing economic risks associated with heat stress and poor climate control.

Access the Ikeuchi USA LinkedIn Newsletter Article Here: Environmental Control for Poultry Houses

- Not sure which product is right for you?

- Curious about the total cost?

- Wondering where to start?

- We’re here to help – reach out with any questions.