Spray Gun Unit with BIM Nozzles BIMV

Pneumatic flat spray nozzles with a wide adjustable range of fl…

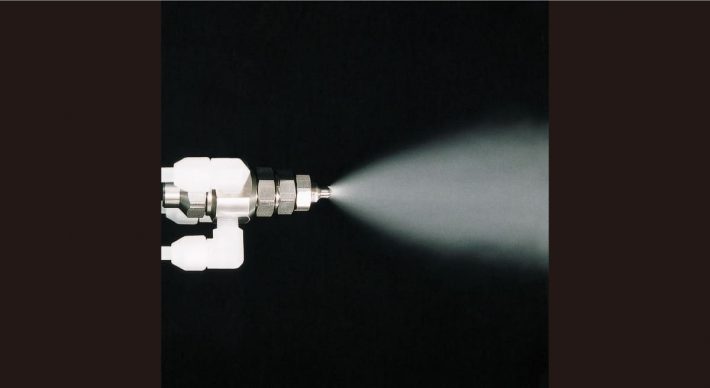

Steam-driven Spray Nozzles

Pneumatic spray nozzles utilizing steam for atomizing liquid instead of compressed air.

| Main Material | S316L, S304 |

|---|---|

| Air Supply | Steam |

| Liquid Feeding System | Liquid pressure |

| Air-liquid Mixing System | Enternal mixing outer air type |

| Spray Droplet Measuring Method | Immersion Sampling Method |

| Fog Classification | Semi-fine fog |

| Mean Droplet Diameter | 40–200 μm |

| Spray Capacity (Flow-rate) | 10–1,200 L/hr *1 |

- Materials: Click here for full material descriptions, including chemical and heat resistance.

- Fog Classification: Based on spray droplet size. Click here for details.

*1) Spray capacity measured at steam pressure of 0.1–0.6 MPa and liquid pressure of 0.1–0.5 MPa.

Note: To control the spray out of the JOKIJet nozzles, control by steam pressure and spray capacity is recommended.

Attempts to control the spray by controlling the steam pressure and liquid pressure may not allow stable spray control.

For more details on JOKIJet spray control, please contact a sales representative.

• Innovative pneumatic spray nozzle using steam instead of compressed air to produce fine (semi-fine) atomization.

• Great savings on running costs realized by utilizing steam from an existing boiler facility.