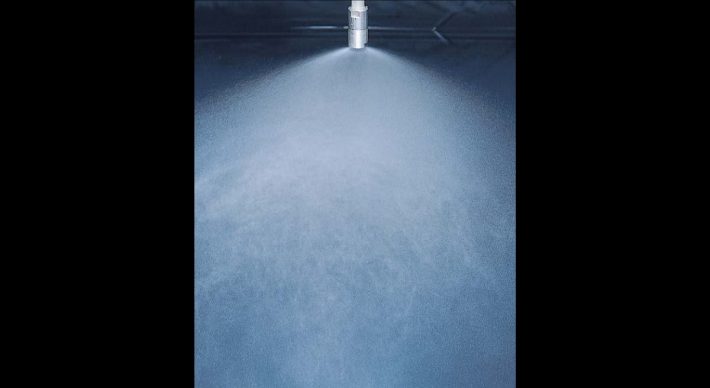

Large Capacity Fine Fog Spray Nozzles (Large Spray Capacity) GSIMⅡ

Pneumatic spray nozzles, producing a large amount of fine fog f…

Full Cone Spray Nozzles (Blower Air Type)

Pneumatic full cone spray nozzles utilize blower air for atomization, resulting in running cost reductions of 1/2 to 2/3 compared to nozzles with equivalent performance using compressed air.

| Main Material | S316L, S304 |

|---|---|

| Air Supply | Blower air |

| Liquid Feeding System | Liquid pressure |

| Air-liquid Mixing System | Internal mixing outer air type |

| Spray Droplet Measuring Method | Laser Doppler Method |

| Fog Classification | Semi-fine fog |

| Mean Droplet Diameter | 40–80 μm |

| Spray Capacity (Flow-rate) | 100–1,000 L/hr *1 |

| Spray Angle | 20º |

- Materials: Click here for full material descriptions, including chemical and heat resistance.

- Fog Classification: Based on spray droplet size. Click here for details.

*1) Measured at liquid pressure of 0.1–2.0 MPa.

Note: Please refer to the catalog for detailed specifications including spray capacity (flow rate), mean droplet diameter, liquid and air inlet sizes.

• Full cone spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 40 μm or more (*2).

• Produces semi-fine atomization having no large droplets. When the mean droplet diameter is 80 μm, the maximum droplet diameter is 180 μm (*2) under air-water ratio of 250.

• Energy-saving for blower-use. Low running cost.

• Spray angle of 20゚.

*2) Measured by Laser Doppler Method.

Pneumatic spray nozzles, producing a large amount of fine fog f…

Hollow cone spillback nozzles with a variable spray flow rate.

Pneumatic full cone spray nozzles produce a semi-fine to semi-c…