Preventing ESD Damage in SMT | 7 Benefits of Dry Fog Humidification (Part 2)

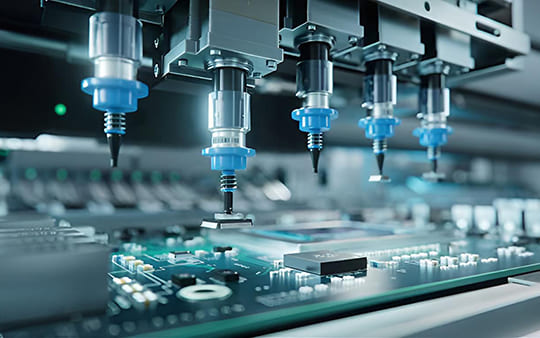

In surface-mount technology (SMT) processes, humidity control is essential to prevent electrostatic discharge (ESD) damage and problems with static electricity or dry air. Among all the methods to control humidity, the Dry Fog* Humidification system from IKEUCHI is the only one able to achieve all seven of these benefits.

*A fog formed out of ultrafine water droplets, each measuring 10 μm or less in diameter, which are created by specialized spray nozzles, to instantly evaporate into the air or bounce off any object instead of bursting on impact.

1. Preventing ESD damage

2. Reducing pick-and-place errors

3. Maintaining consistent solder print quality

4. Reducing airborne particles

5. Significant reduction in operating costs

6. Reducing cooling costs

7. Less sick leave

This article will discuss operating costs, cooling costs, and the work environment, as shown in the table of contents under 5, 6, and 7.

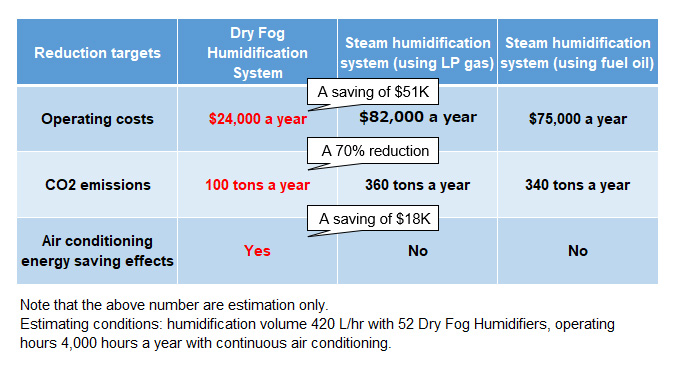

From all the available humidification methods, to show the drastic savings in operating costs, the steam humidification system using fuel oil was chosen to compare with the Dry-fog humidification system.

The table below shows a case where the operating costs were reduced by 68%, which comes out to a savings of $50K, along with a CO2 emissions reduction of 70%. This is also a significant contribution towards the Sustainable Development Goals (SDGs).

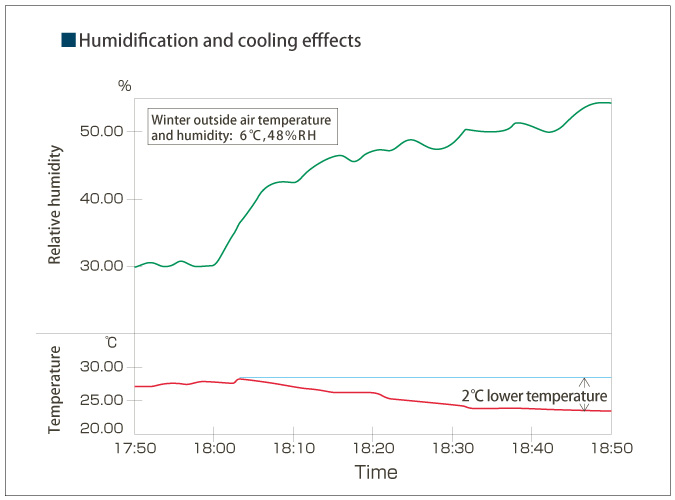

Using the Dry Fog humidification system indoors, the cooling effect of the fog also lowers the ambient temperature by approximately 2 degrees C. In a surface-mount facility equipped with reflow soldering ovens the air conditioning runs year-round to counter the increased room temperature caused by the exhaust heat of the ovens. Operating the Dry Fog system not only stabilizes the humidity level but also reduces the operating costs for the A/C. As shown in the above table, one of our clients saved $18K/year in cooling expenses.

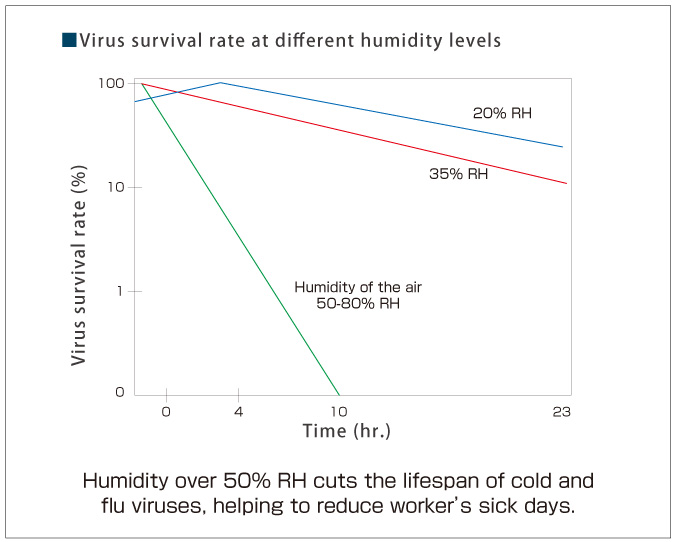

Lastly, the Dry Fog humidification system reduces the number of sick days taken by employees due to cold and flu, by creating a healthier work environment.

It is well known that maintaining a relative humidity of 50% or above significantly reduces the survival time of cold and flu viruses. As a matter of fact, many of our clients who installed the Dry Fog humidification system have noticed a significant drop in sick leave during the winter months and welcome the side effect of better employee health.

Controlling humidity in SMT processes provides seven benefits. Among all the methods to control humidity, the Dry Fog Humidification system from IKEUCHI is the only one able to achieve all of these benefits.

1. Preventing ESD damage

2. Reducing pick-and-place errors

3. Maintaining consistent solder print quality

4. Reducing airborne particles

5. Significant reduction in operating costs

6. Reducing cooling costs

7. Less sick leave

This was the last article in this series. Find our previous articles by clicking on the links for Benefits 1 and 2 or Benefits 3 and 4.