Basics of Spray Nozzles | Classification of Spray Droplet Size

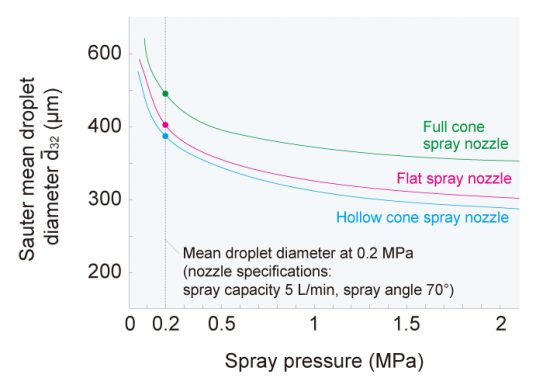

The mean droplet diameter is an important factor in selecting nozzles and designing nozzle-related equipment. It varies depending on the type of spray nozzle, liquid pressure, and spray capacity.

If the spray conditions, such as spray pressure, capacity and angle, are kept the same, the mean droplet diameter of a hollow cone spray nozzle is the smallest among hydraulic nozzles.

The smaller the mean droplet diameter, the larger the surface area that contacts air, increasing the contact efficiency and effect on chemical reactions, absorption, adsorption, etc.

Hollow cone spray nozzles are suitable for cooling and purifying gases, humidifying, and chemical reactions.

Spray droplet diameter is an important element in selecting nozzles and designing nozzle-related equipment.

IKEUCHI, “The Fog Engineers”, uses the immersion sampling method and the laser analyzer to measure spray droplet diameters.

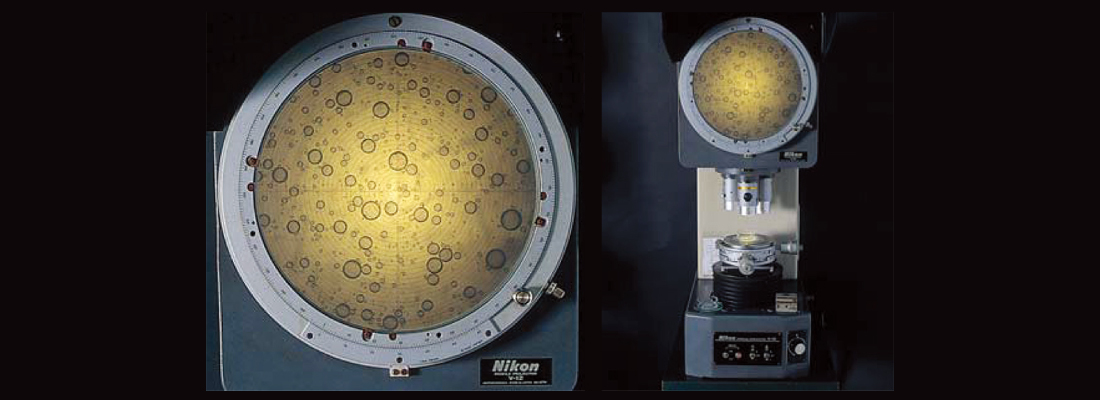

Immersion sampling method

Immersion sampling method

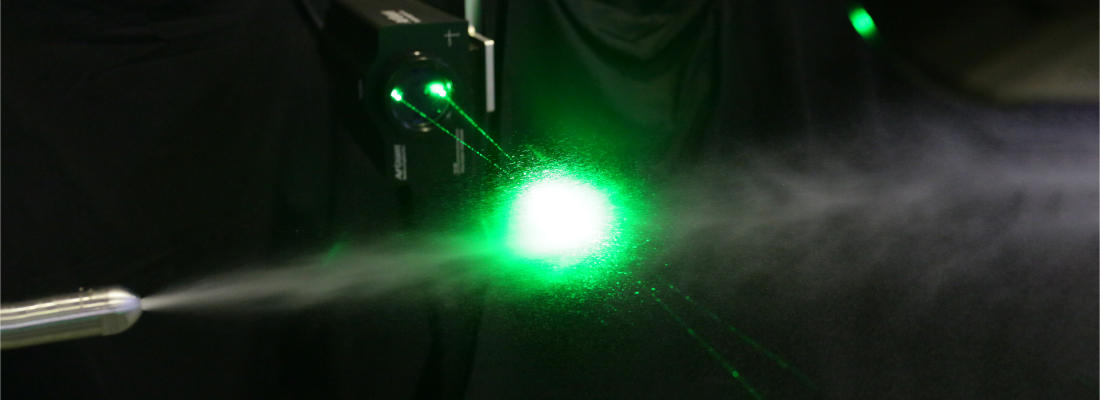

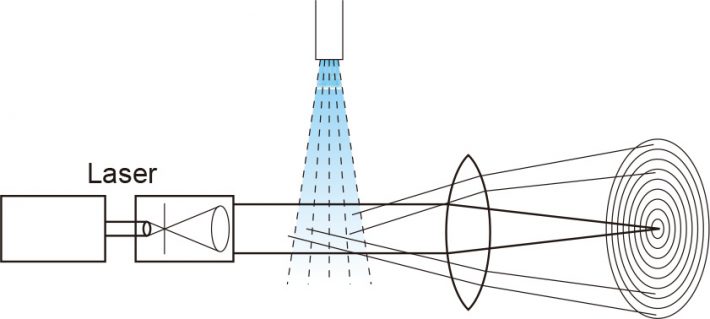

Laser analyzer

Laser analyzer

In an immersion sampling method, droplets are collected on a glass plate thickly coated with silicone oil and are immediately photographed at high magnification for subsequent count of those number by size.

The collected droplets quickly settle in the silicone oil and do not evaporate even in strong light while being photographed. Remaining suspended in the silicone oil, they are measured as perfect spheres.

IKEUCHI, “The Fog Engineers”, uses the immersion sampling method to measure droplet diameter sprayed mainly with hydraulic nozzles.

A laser beam scatters at the surface of droplets in the laser beam path and the diffraction pattern caused by interference of scattered light is focused behind the droplets. This method can simultaneously measure all droplets in the laser beam path.

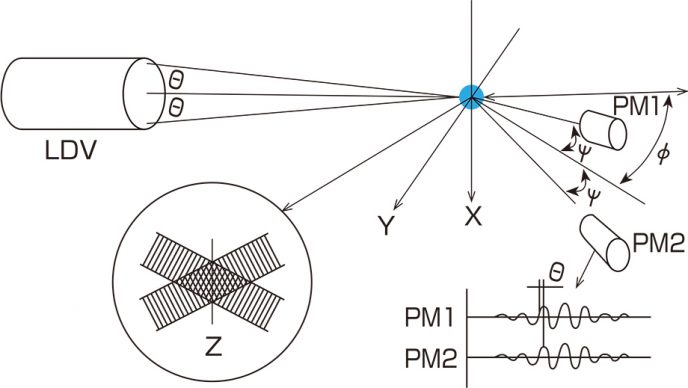

This method forms an interference fringe by crossing two laser beams. Two or more receivers located at a certain distance from the spray detect the phase difference and calculate diameter of droplets having passed through this interference fringe.

As this method measures droplets one by one, it is relatively less affected by droplet density and, as another advantage, it can measure droplet velocity simultaneously.

IKEUCHI, “The Fog Engineers”, uses the laser Doppler method to measure droplet diameter sprayed mainly with pneumatic nozzle.

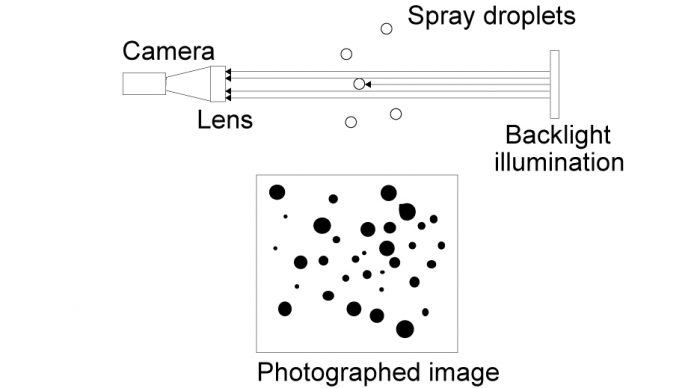

Backlight illuminated shadows of droplets in various sizes are photographed and converted to circular shapes, from which the droplet diameters are calculated.

This method enables the measurement of non-spherical coarse droplets that cannot be measured by the laser analyzer.

On the other hand, it is not suitable for measuring fine droplets due to the low magnification of the camera. Also, when the droplets are dense, the overlapped multiple droplets could be measured as a single droplet, thus its droplet size may appear larger than the actual size.

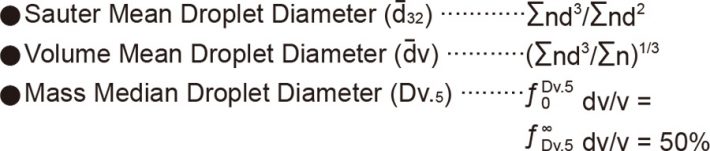

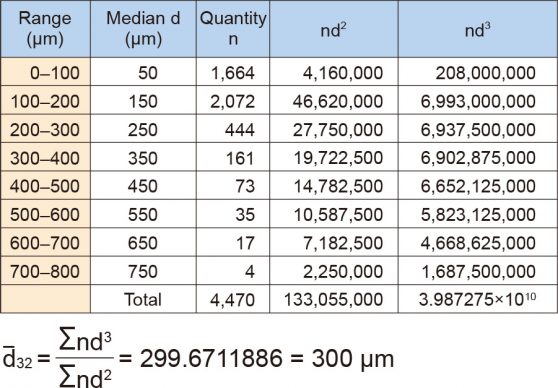

Mean droplet diameter is one of the important elements in selecting nozzles and designing nozzle-related equipment. The following three are commonly used.

In chemical processes such as cooling, evaporation, combustion and drying, it is common to determine efficiency using the ratio of volume-surface area, i.e. specific surface.

Because a small portion of large droplets is more influential over the rate of reaction than a large portion of small droplets, it is advisable to use Sauter Mean Droplet Diameter as representative droplet sizes.

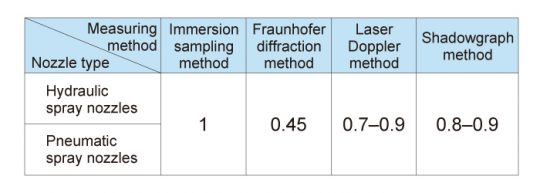

Results will differ, depending on the method used to measure. If the Sauter mean droplet diameter measured with the immersion sampling method

equals 1, as relative coefficient number, this value will be different when measured with other methods, as shown on the right.