Basics of Spray Nozzles | Classification of Spray Droplet Size

Precision in fluid control is critical across industries, and a data-driven approach ensures the best possible performance. At Ikeuchi, our research and development facility provides extensive testing and analysis to refine and customize nozzle solutions for specific applications. By leveraging advanced measurement techniques and real-world testing, we aim to support industries in achieving optimal efficiency and reliability.

Each application presents unique challenges, requiring precise control over factors such as droplet size, spray distribution, and flow rate. Through cutting-edge measurement systems, high-speed imaging, and fluid dynamics simulations, our team gathers quantifiable insights to fine-tune nozzle performance under various conditions.

Our research facility conducts extensive real-world testing to ensure optimal functionality. Key parameters analyzed include:

To achieve these precise measurements, we employ a range of testing methods, including:

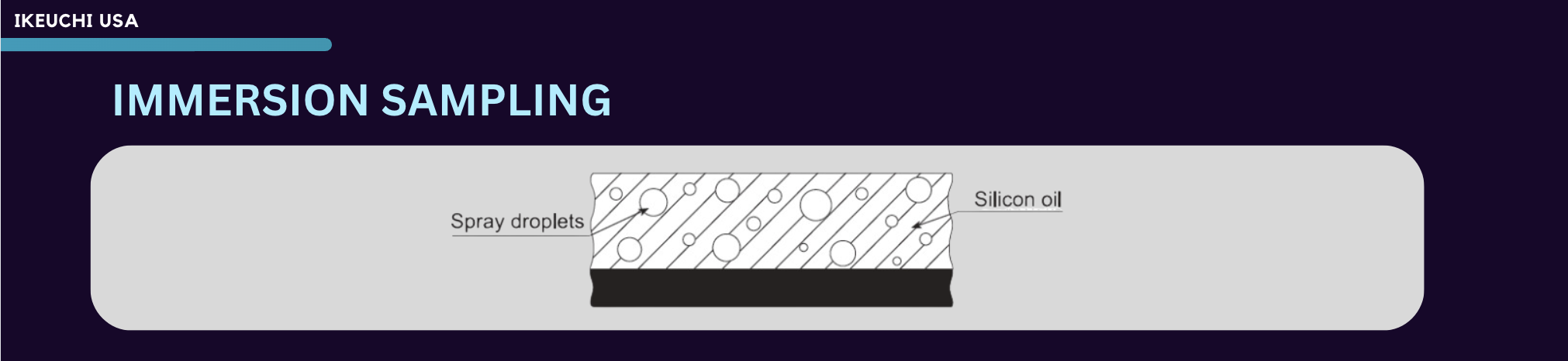

Uses a silicone oil-coated glass plate to capture and measure droplet sizes. Effective for larger droplets but may overestimate fine and ultra-fine fog sizes due to evaporation.

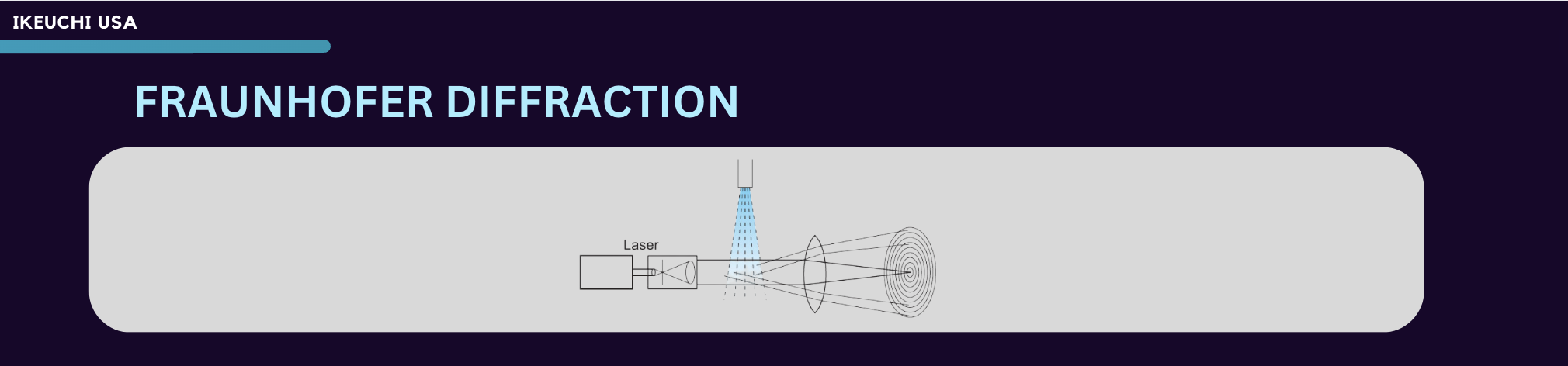

A laser-based method that analyzes diffraction patterns created by droplets. This technique enables simultaneous measurement of multiple droplets but may introduce errors in high-density sprays due to multiple dispersion effects.

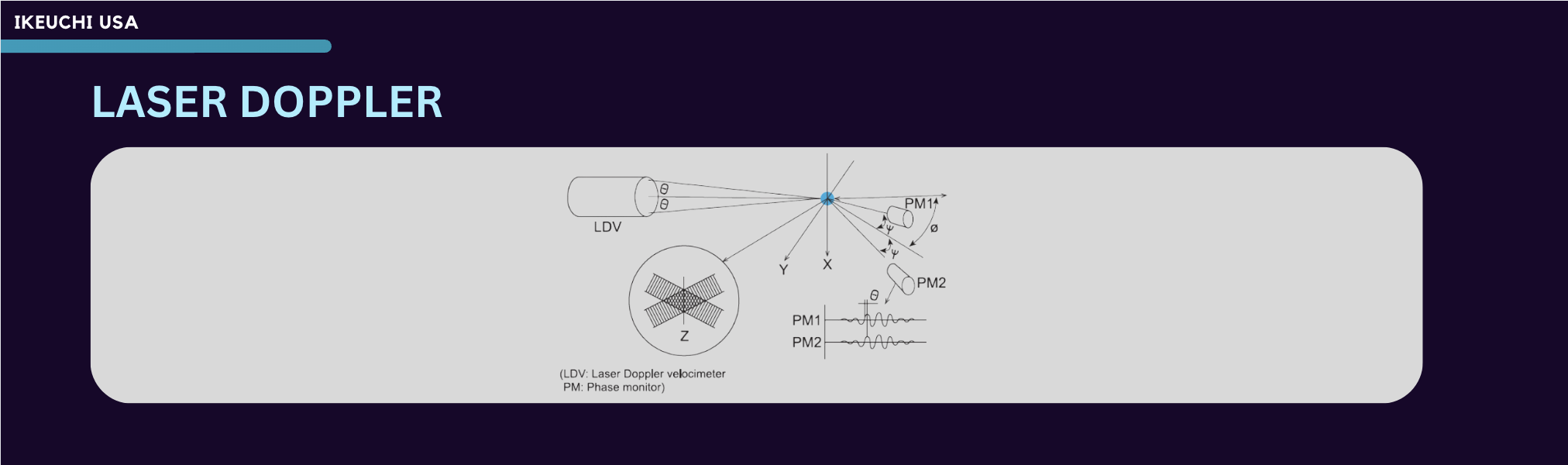

Uses two intersecting laser beams to measure droplet size and velocity at a single point in the spray. This method is highly accurate and unaffected by spray concentration variations but is limited to point-based measurements.

By methodically assessing these variables, we help industries such as agriculture, electronics, and manufacturing refine their processes with confidence.

Customization in nozzle design requires more than adjustments—it involves a data-driven, iterative approach. By analyzing performance metrics and refining designs accordingly, we work toward optimized solutions through:

We utilize the immersion sampling method in our hydraulic catalog to provide an indication of droplet sizes across different nozzle series, while our pneumatic catalog incorporates multiple measurement techniques tailored to specific products.

Effective fluid control is a collaborative effort, and working closely with industries allows for targeted refinements based on real-world requirements. Through transparent data analysis and rigorous testing, we contribute to process improvements that enhance efficiency and reliability across various applications.

By emphasizing data-driven decision-making, we strive to support industries with customized solutions that address unique challenges. For those looking to refine fluid control processes, a research-backed approach can provide measurable improvements and long-term benefits.