Technical Library

- HOME

- Technical Library

- Pacific Hardwood – Craftsmanship Meets Innovation in Climate Challenges

Pacific Hardwood – Craftsmanship Meets Innovation in Climate Challenges

Solutions or Products Featured

in This Case Study

About Pacific Hardwood

Pacific Hardwood is one of the nation’s leading manufacturers of engineered and solid hardwood flooring, mouldings, stair components, and architectural panels. For more than 10 years, they have been a valued customer of Ikeuchi, a partnership that reflects their commitment to quality, precision, and innovative manufacturing solutions. Guided by a mission of “uncompromising excellence,” every product is crafted from start to finish within their fully integrated U.S.-based facility, from lumber yard to rough mill to prefinishing lines, ensuring both quality and efficiency.

Rooted in a philosophy that blends traditional American craftsmanship with forward-thinking innovation, Pacific Hardwood is dedicated to precision, beauty, and enduring performance.

The Challenge

At the heart of Pacific Hardwood’s operation is the use of PUR (polyurethane) glue, a superior adhesive offering fast “green strength” via heat and pressure, followed by chemical curing through ambient moisture. However, when humidity dips too low, the moisture-dependent curing fails, and the bonds do not form properly.

To uphold its high production standards and customer commitments in Southern California’s dry climate, Pacific Hardwood recognized the need to better manage humidity in its pressing process. Without consistent humidity, it became increasingly challenging to maintain optimal operating conditions.

The team carefully evaluated a range of off-the-shelf humidification options, ranging from a halo design to systems that created rainforest-like effects. While some increased humidity dramatically, they also introduced unwanted side effects such as excess moisture around equipment. These evaluations reinforced Pacific Hardwood’s decision to seek a solution that would provide precise humidity control without over-humidification.

The Solution – Ikeuchi’s Dry Fog

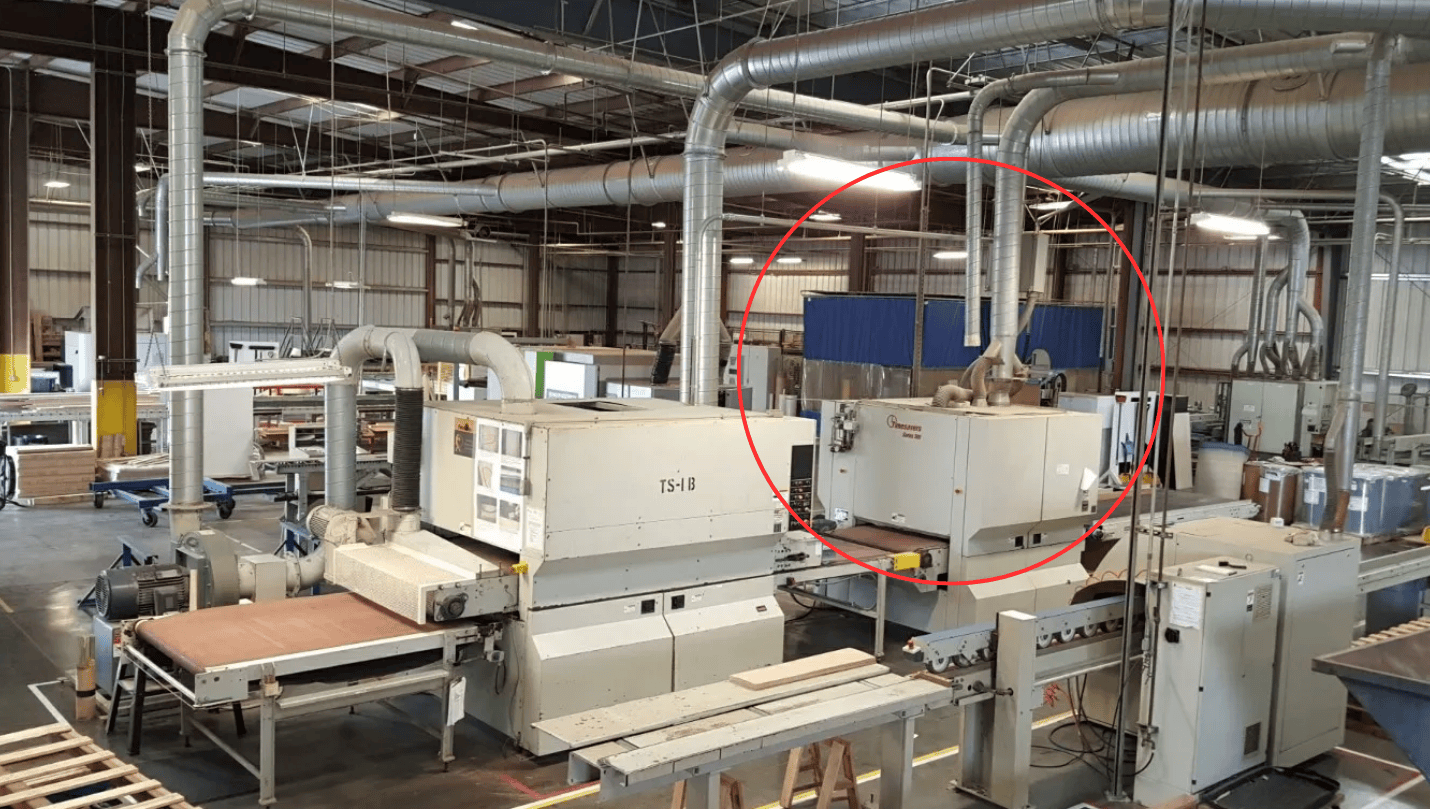

Pacific Hardwood implemented Ikeuchi’s AKIMist®E Dry Fog Humidification System, integrated within a custom curtain setup around the pressing area. This precisely engineered solution maintains optimal moisture levels consistently, even on the driest days, while ensuring the environment remains controlled and balanced.

The Impact

By proactively controlling humidity with the AKIMist®E system, Pacific Hardwood has been able to avoid costly production disruptions and protect product quality. Before AKIMist, extended periods of low humidity could result in tens of thousands of dollars of lost productivity per day. Additionally, pushing the limits of low humidity risked delamination, which could lead to costly field failures and jeopardize accounts.

On particularly dry days, the system provides an additional 3 to 4 hours of pressing time per day, effectively preserving full shifts. Across the year, this ensures smooth operations while protecting both equipment and product integrity.

Results That Uphold Quality and Craftsmanship

Objective

|

Outcome

|

| Consistent Production | The AKIMist system is run about 60 percent of the year to ensure humidity never falls below the required minimum. |

| Extended Production Time | On low-humidity days, Pacific Hardwood gains an additional 3 to 4 hours of pressing time per day, effectively preserving full shifts that would have been lost. |

| Avoided Shutdowns | Before AKIMist, 20 to 30 days per year required complete shutdowns. Each shutdown represented tens of thousands of dollars in lost productivity plus labor and overhead costs. |

| Operational Reliability | Early shutdowns are now rare and production schedules remain on track even in challenging conditions. |

| Equipment Safety | No rust or water-induced electrical issues thanks to precise humidity control. |

Case in point:

“IKEUCHI’s misting system has proven to be reliable, efficient, and essential to our production success. We highly recommend their solutions to any manufacturer facing similar humidity challenges.”

— Operations Management, Pacific Hardwood

Why This Matters for Pacific Hardwood

This is not just a technical fix. It is a reinforcement of Pacific Hardwood’s core values:

- Preserving craftsmanship integrity: The ideal curing of PUR adhesive ensures the quality and beauty of each floor, moulding, or panel remains uncompromised.

- Maintaining vertical excellence: Their integrated U.S. manufacturing processes, already a point of pride, run smoothly without delays, aligning with their promise of speed and reliability.

- Reflecting innovation rooted in tradition: Implementing a precise environmental control system shows their commitment to elevating craftsmanship through thoughtful innovation.

Final Takeaway

Pacific Hardwood’s decade-long partnership with Ikeuchi reflects a relationship built on trust, collaboration, and shared dedication to quality. We are proud to support their operations and are grateful for the opportunity to contribute to their continued success in maintaining craftsmanship, efficiency, and customer satisfaction.

Access the Ikeuchi USA LinkedIn Newsletter Article Here:

- Not sure which product is right for you?

- Curious about the total cost?

- Wondering where to start?

- We’re here to help – reach out with any questions.