News & Notices

- HOME

- News & Notices

- Move It Where You Need It: Portable Dry Fog Spot Humidification for Static Control | Newsletter Vol. 30

Move It Where You Need It: Portable Dry Fog Spot Humidification for Static Control | Newsletter Vol. 30

When plastic lines slow down, it’s easy to blame the equipment. But the real trigger is often low humidity.

Plastics are highly sensitive to humidity. When the air becomes too dry, electrostatic charge builds up easily on products and packaging—leading to parts sticking together, dust attraction, unstable conveying, and in some cases even safety risks from static sparks.

For a deeper look, read our Europe team’s article: How does humidity affect plastic?

Preventing Bottle Toppling with Targeted Dry Fog Humidification

A plastic bottle manufacturer faced repeated interruptions in the shipping area. Bottles aligned on a conveyor were pushed onto pallets—but during dry periods, static caused bottles to cling together. The result was a chain reaction of “domino toppling,” forcing stops and manual re-handling.

Watch a short case study video (under 2 minutes) to see how a portable Dry Fog humidifier removed this bottleneck:

▶ Read Full Case Study: Dry Fog Prevents Bottle Toppling in a Plastic Bottle Plant

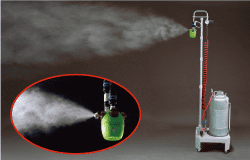

AE-T Set highlights:

- Portable & relocatable (casters) for changing trouble spots

- No piping or fixed installation — start up by simply connecting compressed air

- Ultra-fine Dry Fog (≤10 μm) — humidification without wetting products or equipment

Beyond Packaging: Static Control in High-risk Plastic Processes

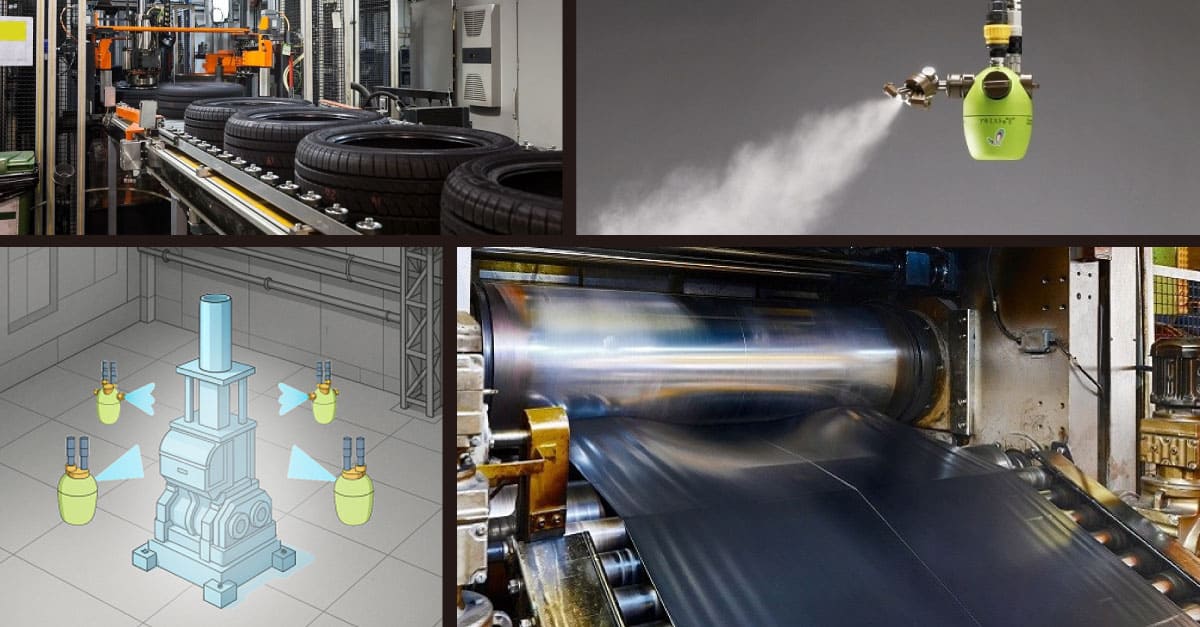

Humidity control isn’t only about handling and cleanliness—it can also be a critical safety measure. In tire manufacturing, the mixing process around Banbury Mixers generates intense heat, leaving areas hot and dry—conditions where static sparks can pose a serious fire risk.

Discover how targeted Dry Fog humidification helped reduce static ignition risk in a tire mixing process:

▶ Read Full Case Study: Dry Fog Prevents Static Ignition in Tire Manufacturing

Portable Dry Fog Humidification — Easy to Move, Easy to Deploy, and Built for Targeted Control

Whether the challenge is conveying instability, dust attraction, product defects, or static-related safety concerns, humidity control is one of the most effective countermeasures available. Many plastic production facilities target 40–60% RH to help suppress static build-up while supporting more consistent production conditions.

When mobility, easy setup, and non-wetting performance are required, the AE-T Set is a practical option—especially where fixed systems are difficult to install or where relocation to emerging trouble spots is needed.

If static is causing stoppages or quality issues in your production process, contact us—we would be happy to discuss your layout and recommend an optimal humidification strategy.