Surface Washing Nozzles for Rapid Sand Filters at Water Treatment Plants

Solutions or Products Featured

in This Case Study

The customer was a plant engineering company contracted to renovate a wastewater treatment facility.

At the facility, once the rainwater storage basin was drained, staff had to clean the basin walls by hand—an intensive and time-consuming task.

To reduce this burden and automate the work, the engineering company began designing a cleaning system using spray nozzles.

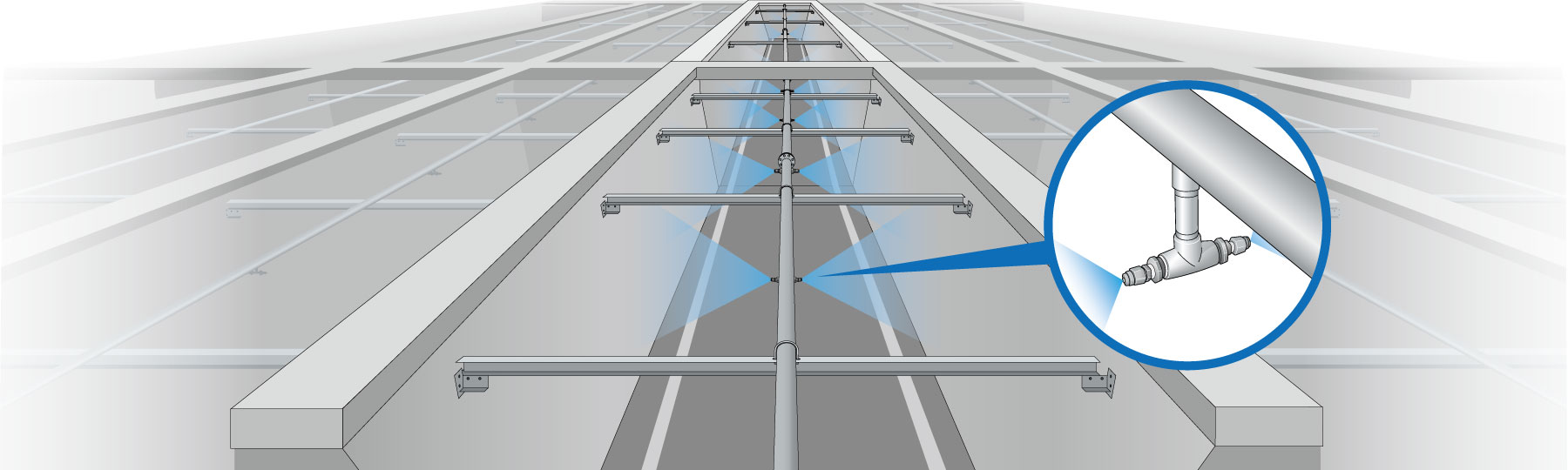

The rainwater storage basin was 4 meters wide and 40 meters long.

The company planned a layout in which a water supply pipe was installed along the center of its longitudinal axis, with spray nozzles mounted at regular intervals on the pipe.

Two nozzles were arranged back-to-back at each mounting position to spray toward both sidewalls, enabling both sides to be cleaned simultaneously.

However, the selection of spray nozzles presented a challenge.

They initially considered full cone spray nozzles from another supplier.

While the vertical coverage was sufficient, the horizontal spray width was narrow, raising concerns about uncleaned areas.

To cover the entire surface, they would have needed to reduce the nozzle pitch and add more nozzles.

Because the total available water supply could not be increased, adding more nozzles would have reduced the spray volume per nozzle below the specified level.

To address this, the company consulted IKEUCHI, seeking spray nozzles that could cover the entire wall surface without increasing the nozzle count.

IKEUCHI proposed the DDRP Series, featuring an ultra-thick flat spray pattern with a near-rectangular coverage area.

Compared with a full cone spray nozzle, DDRP provides a wider spray width in the horizontal direction at the same flow rate, enabling full wall coverage without narrowing the installation pitch.

In addition, its strong spray impact helps wash away adhered contaminants reliably.

Adopting this nozzle allowed the cleaning system to be installed as originally laid out.

Since the initial installation, the system has been deployed in other rainwater storage basins, and IKEUCHI’s spray nozzles continue to support maintenance at wastewater treatment plants.