- Made-to-Order

- Clog Resistant

- Industrial Cooling

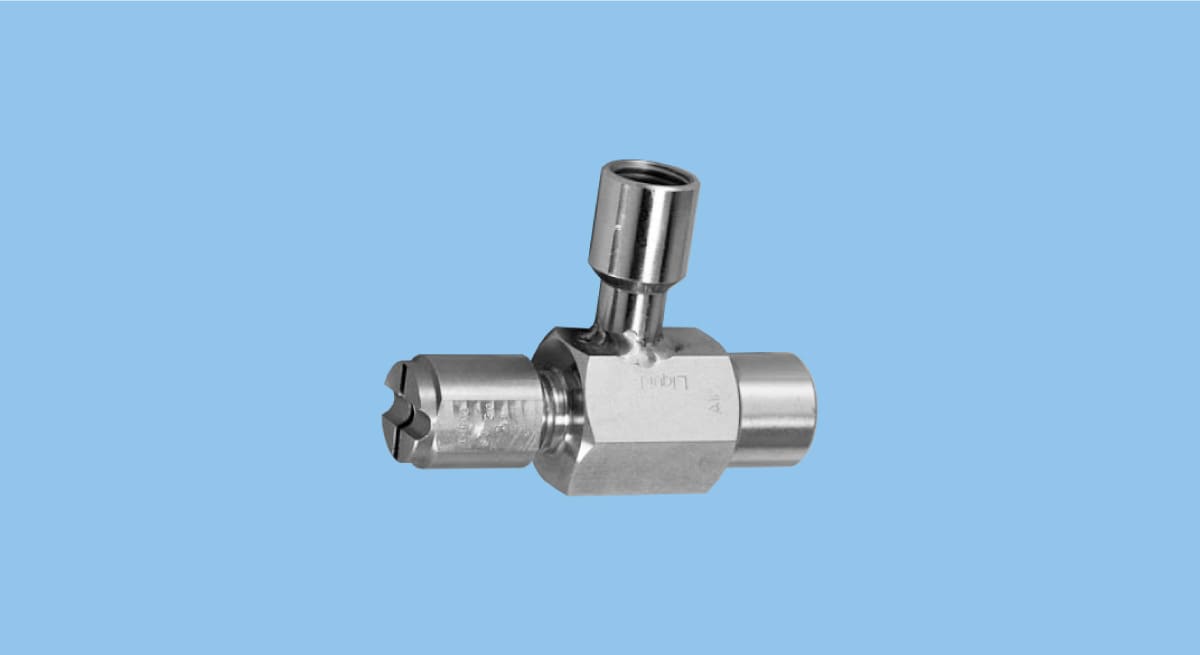

Ultra-thick Even Flat Spray Nozzles

DDA

Large capacity pneumatic spray nozzles, featuring an ultra-thick, flat spray pattern, produce uniform droplets across the entire spray pattern area, with minimal variation in spray angle. Their uniform spray distribution makes them well-suited for use in a multi-nozzle arrangement. Additionally, their large free passage diameter makes them resistant to clogging.

Specs

| Main Material | S303, S304 |

|---|---|

| Air Supply | Compressed air |

| Liquid Feeding System | Liquid pressure |

| Air-liquid Mixing System | Internal mixing pre-mix type |

| Spray Droplet Measuring Method | Fraunhofer Diffraction Method |

| Fog Classification | Semi-coarse fog, Semi-fine fog |

| Mean Droplet Diameter | 15–200 μm |

| Spray Capacity (Flow-rate) | 0.14–57.3 L/min |

| Spray Angle | 75º, 80º, 100º, 110º, or 125º *1 |

- Materials: Click here for full material descriptions, including chemical and heat resistance.

- Fog Classification: Based on spray droplet size. Click here for details.

*1) Criteria for spray angle measurement differs depending on nozzle codes.

Note: Please refer to the catalog for detailed specifications including spray capacity (flow rate), mean droplet diameter, liquid and air inlet sizes.

Resources for Download

• Thick flat spray pneumatic nozzle producing a large volume of semi-fine atomization with a mean droplet diameter of 50 μm or more (*2).

• Liquid pressure type under the liquid pressures of 0.07–0.7 MPa.

• Large turn-down ratio with minimal variation in spray angle.

• Uniform distribution suitable for multiple-nozzle arrangements.

• Thicker flat spray pattern covers wider area.

• Large free passage diameter minimizes clogging.

• Spray angle of 75°, 80°, 100°, 110°, or 125°.

*2) Measured by Fraunhofer diffraction method.

Applications

- Cooling: Gas, steel plates, steel pieces, pipes, moldings, etc.

- [Steelmaking industry]

- Steel making process: Cooling continuous casted steel (bloom, slab short side, billet), cooling roll of casting machine

- Rolling mill process: Cooling steel plate on continuous annealing line, roll in heat treatment, and magnetic steel

Industries where this nozzle is used

- Steelmaking

- Pollution Control