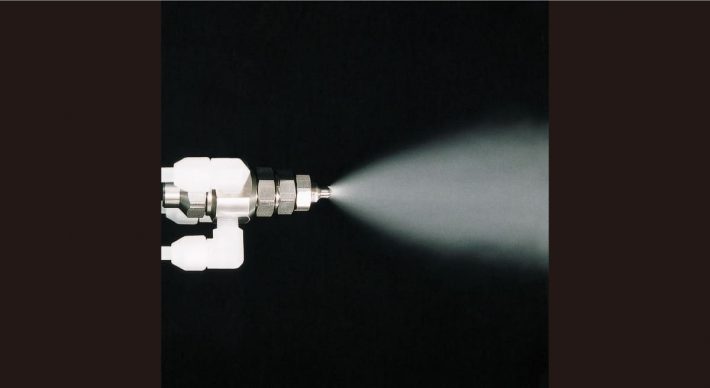

Spray Gun Unit with BIM Nozzles BIMV

Pneumatic flat spray nozzles with a wide adjustable range of fl…

Ultra-compact, Low Flow Rate Flat Spray Nozzles (Suction Type)

High-performance pneumatic flat fan spray nozzles, a further miniaturized version of the compact fine fog flat spray nozzle CBIMV-S Series.

This product is of the suction type.

| Main Material | S303 |

|---|---|

| Air Supply | Compressed air |

| Liquid Feeding System | Liquid siphon |

| Air-liquid Mixing System | Internal mixing inner air type |

| Spray Droplet Measuring Method | Laser Doppler Method |

| Fog Classification | Fine fog |

| Mean Droplet Diameter | 20–30 μm |

| Spray Capacity (Flow-rate) | 0.1–0.74 L/hr |

| Spray Angle | 80º*1 |

| Spray Width | 160–170 mm *2 |

- Materials: Click here for full material descriptions, including chemical and heat resistance.

- Fog Classification: Based on spray droplet size. Click here for details.

*1) Spray angle measured at compressed air pressure of 0.3 MPa and liquid siphon height of 100 mm.

*2) Measure at spray distance of 100 mm from nozzle and liquid siphon height of 100 mm.

Note: Please refer to the catalog for detailed specifications including spray capacity (flow rate), mean droplet diameter, liquid and air inlet sizes.

• Flat spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 30 μm or less.**

• Ultra-compact size. About 42 mm in total length including control adaptor.

• Liquid siphon feed type (liquid pressure device is not required).

• Even spray distribution across the entire spray area.

• Spray angle of 80゚. *

• Capable of spraying smallest flow rate among all of our pneumatic spray nozzles.

• Spray ON/OFF can be regulated by switching the pilot air ON/OFF (adaptor type SP) or by turning compressed air ON/OFF (adaptor type SN).

*Spray angle measured at compressed air pressure of 0.3 MPa and liquid siphon height of 100 mm.

**Mean droplet diameter measured by laser Doppler method.