Automating Tank Cleaning for Waste Liquid Tankers at Food Processing Plants

Note: The product used in this case is a custom version of the ES-PTFE Series, as detailed in the following article.

Solutions or Products Featured

in This Case Study

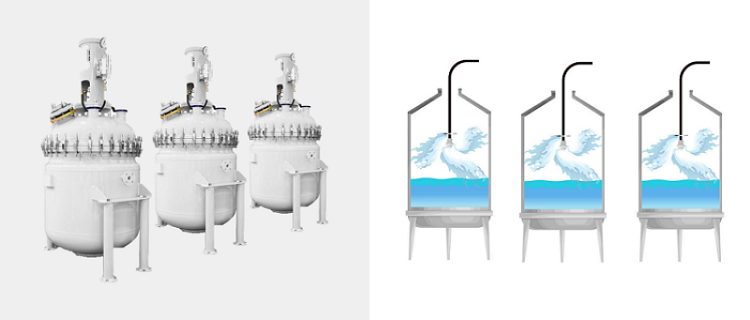

A plant engineering company was working on designing tanks for a user—a chemical plant. During this process, the user requested adding a CIP cleaning function to glass-lined tanks used in their chemical manufacturing processes, posing significant challenges for the company.

While the company had extensive experience in delivering standalone glass-lined tanks, this was their first attempt to incorporate a cleaning function. To meet this new requirement, they consulted us to leverage our extensive lineup of tank cleaning nozzles.

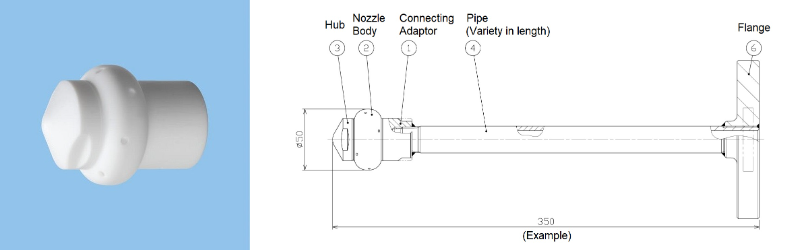

To accommodate the chemical manufacturing process, we selected the PTFE (Teflon) tank cleaning nozzle “ES-PTFE Series,” which offers excellent chemical resistance, and designed it to match the flow rate specified by the end user.

Additionally, we combined PTFE piping and flanges with the ES-PTFE nozzle to create a complete all-PTFE nozzle header, providing a comprehensive solution rather than just a standalone nozzle.

Furthermore, we offered piping in multiple lengths, allowing for a flexible design that can accommodate tanks of varying diameters and heights.

The tank cleaning nozzles, carefully designed to match the size of each tank, deliver high performance across various tanks and processes, significantly contributing to stable operations and labor savings.