Shielding Operators: Preventing Heatstroke at a Propane Refill Station

A metal fabrication factory that produces steel lockers for office use faced a critical challenge: improving the working environment on the production floor.

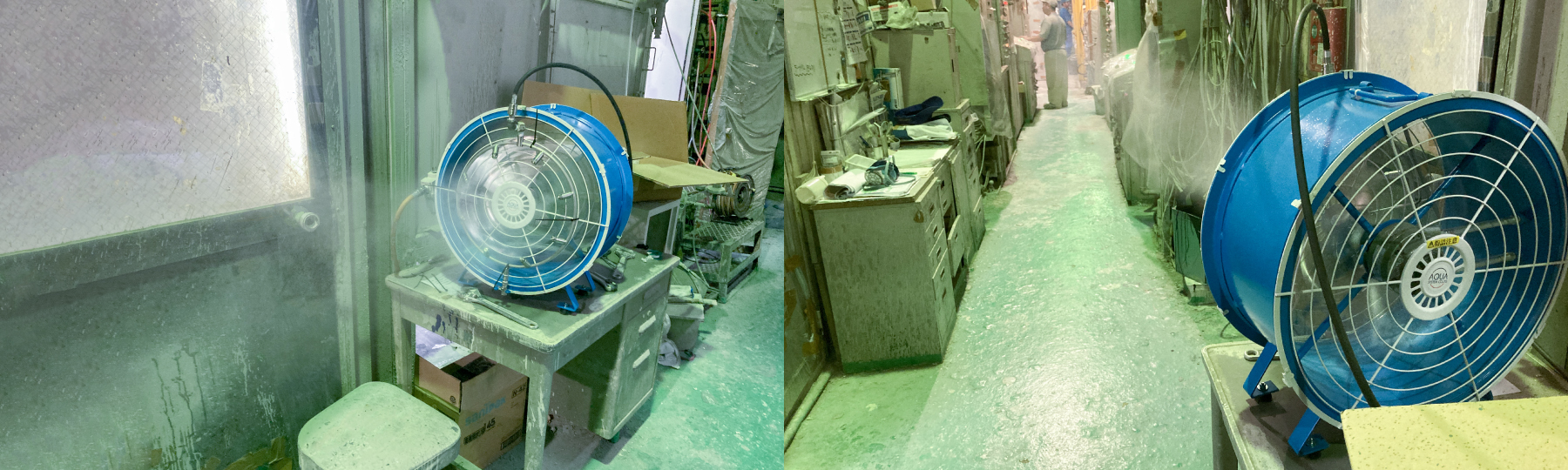

One significant issue was the coating process, where products were painted and baked at a high temperature of 140°C in a drying oven. During the summer, ambient temperatures around the oven exceeded 40°C, creating extremely uncomfortable conditions. The passageways, in particular, retained the heat and further worsened the harsh environment.

Our flagship heat relief product, the CLJ-CSA, is a mist fan equipped with spray nozzles that spray water in the form of a fine fog to lower the surrounding temperature through evaporative cooling. This mist fan is highly effective for reducing the burden on operators in high-temperature environments.

Initially, the customer considered introducing the CLJ-CSA, but since it is not explosion-proof certified, it was unsuitable for use near paint processes, leading to the decision not to proceed.

Additionally, obtaining explosion-proof certification would be time-consuming and costly, making it impractical.

The customer then approached us to explore alternative solutions.

While IKEUCHI initially explored the option of introducing an explosion-proof fan, it was clear that the fan alone could not sufficiently lower temperatures—mist was essential to achieve the desired effect. However, adding spray nozzles to the fan would require explosion-proof certification for the entire fan-nozzle unit, posing a significant challenge.

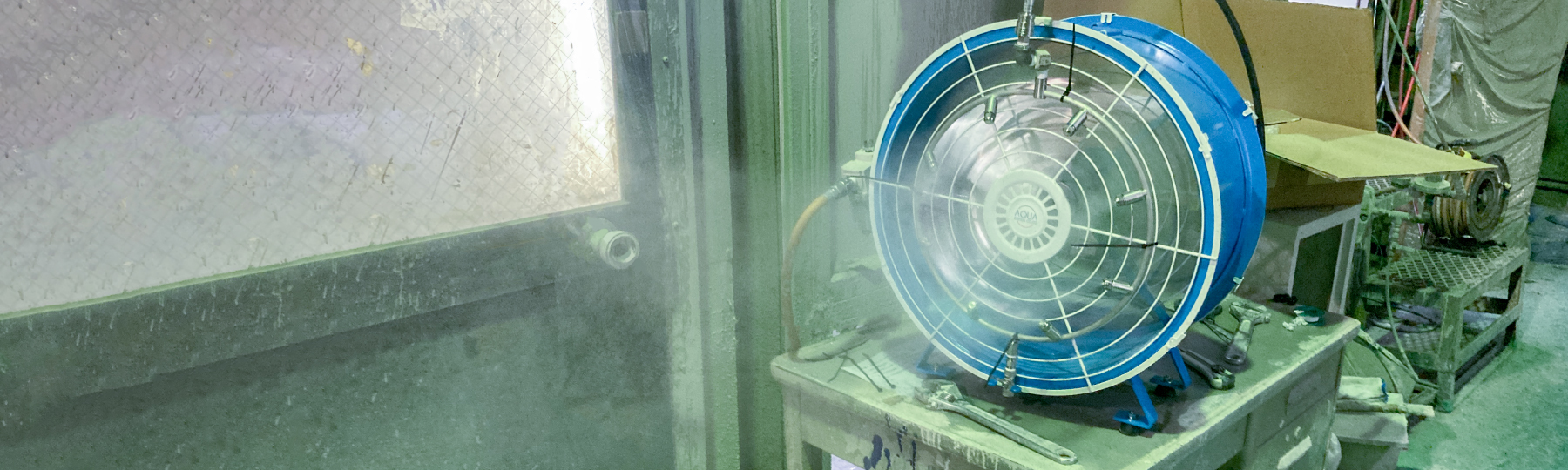

To overcome this challenge, we selected an air-motor fan powered by compressed air, eliminating the need for electricity. Pairing it with the spray nozzle header used for the CLJ-CSA, which does not require explosion-proof certification, created a package free from these requirements. The customer purchased the air-motor fan, and we supplied the nozzle header, delivering a practical and effective solution.

The temperature in the passageways dropped by 5°C, significantly improving the working environment. Operators and site managers expressed their satisfaction, saying, “It feels completely different; it’s now much easier to work.”

This change reduces the risk of heatstroke and will likely boost efficiency and productivity.