Cold Rolling | Water Removal on Pickling Line: Shorter Air Nozzles Reduce Damage Risk

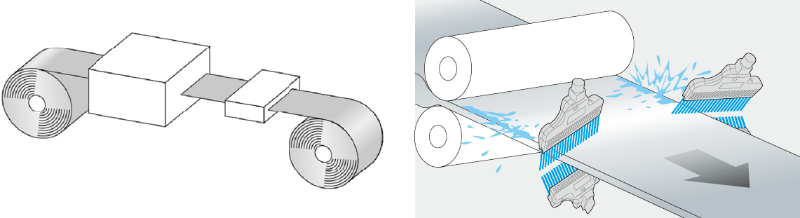

A steel mill was using general-purpose air nozzles for edge wiping to remove water from the edges of steel sheets in the surface treatment process after cold rolling.

However, the nozzles were fixed in place to target the edges of steel sheets of a specific width. This became problematic when the width of the supplied sheets changed. For example, when narrower sheets were fed through, the nozzles aimed at the outside edges of the sheet, causing the air to miss the edges and resulting in insufficient water removal.

Insufficient water removal caused uneven plating color on the steel surface, while even minor defects left water stains. This issue occurred up to five times a week, leading the customer to approach us for a solution.

Our standard air nozzle has a spray width of 42 mm, but we designed a custom nozzle with a 100 mm width to meet wider water removal requirements.

In addition, we proposed a layout where these wide nozzles are positioned at multiple points along the steel sheet’s flow direction, symmetrically arranged with varying width intervals.

This layout allows for flexible adjustments to different sheet widths: outer nozzles are used for wider sheets, while inner nozzles are activated for narrower sheets, ensuring adaptability to width variations.

The system now ensures effective water removal regardless of variations in the width of the steel sheets. As a result, water removal issues have been significantly reduced, contributing to the consistent maintenance of product quality.