Steel Sheet Surface Treatment | Edge Water Removal with Custom Air Knife for Varying Sheet Widths

Solutions or Products Featured

in This Case Study

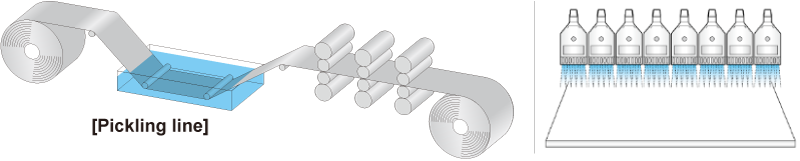

A steel mill using our air nozzles in the pickling line in the cold rolling process faced a recurring issue.

The rippling motion of the steel sheets on the line occasionally caused contact with the air nozzles, resulting in nozzle damage. When the nozzles were damaged, water removal became insufficient, leading to rust formation on the product surface and an increased risk of quality defects.

With the issue occurring as frequently as once every three months, an immediate solution was required. Turning to us for support, the customer sought an effective resolution.

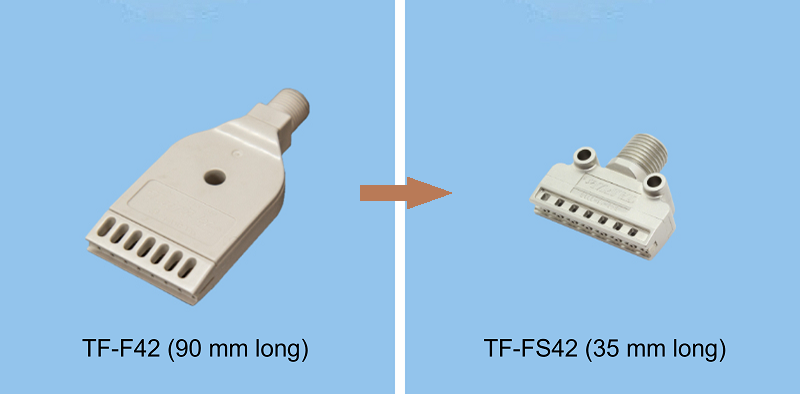

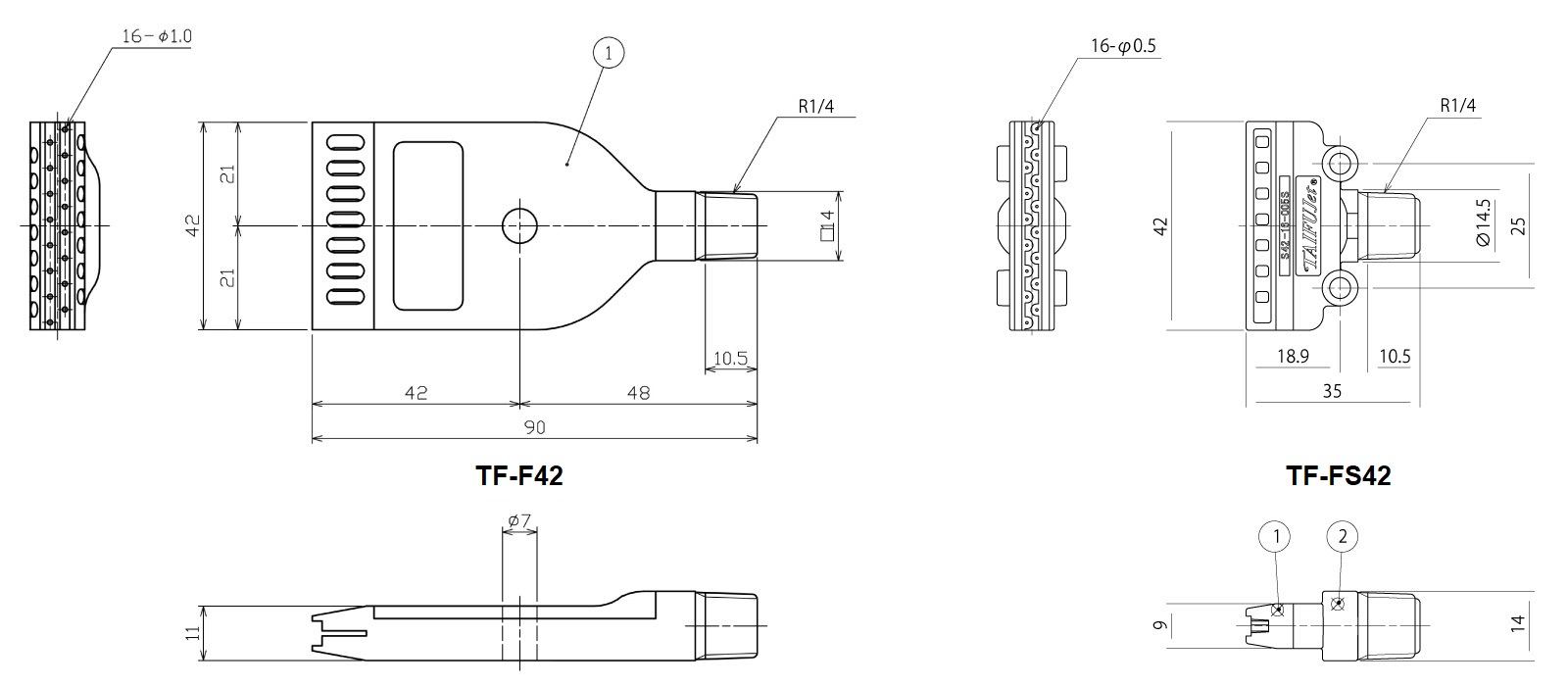

IKEUCHI proposed replacing the existing TF-F42 Series nozzle, with a total length of 90 mm, with the newly developed TF-FS42 Series, which retains the same air blow width of 42 mm while reducing the total length to 35 mm.

Adopting the shorter nozzle design increased the clearance between the nozzle and the sheets by 55 mm. As a result, the rippling motion of the steel sheets no longer posed a risk of contact with the nozzle, effectively minimizing the damage.

Increasing the nozzle-to-sheet distance had no impact on water removal performance. The new design effectively prevents the nozzle damage, even during the rippling motion of the steel sheets. Eliminating maintenance-related line stoppages has ensured stable, uninterrupted operations.