Technical Library

- HOME

- Technical Library

- Reducing Maintenance Burden in Steel Sheet Surface Treatment with Self-Cleaning Spray Headers

Reducing Maintenance Burden in Steel Sheet Surface Treatment with Self-Cleaning Spray Headers

Solutions or Products Featured

in This Case Study

Key Reasons for Implementation

- A solution that significantly reduces maintenance burden and eliminates hazardous tasks.

- Selecting the advanced air-driven model offers even greater ease of operation.

- Not sure which product is right for you?

- Curious about the total cost?

- Wondering where to start?

- We’re here to help – reach out with any questions.

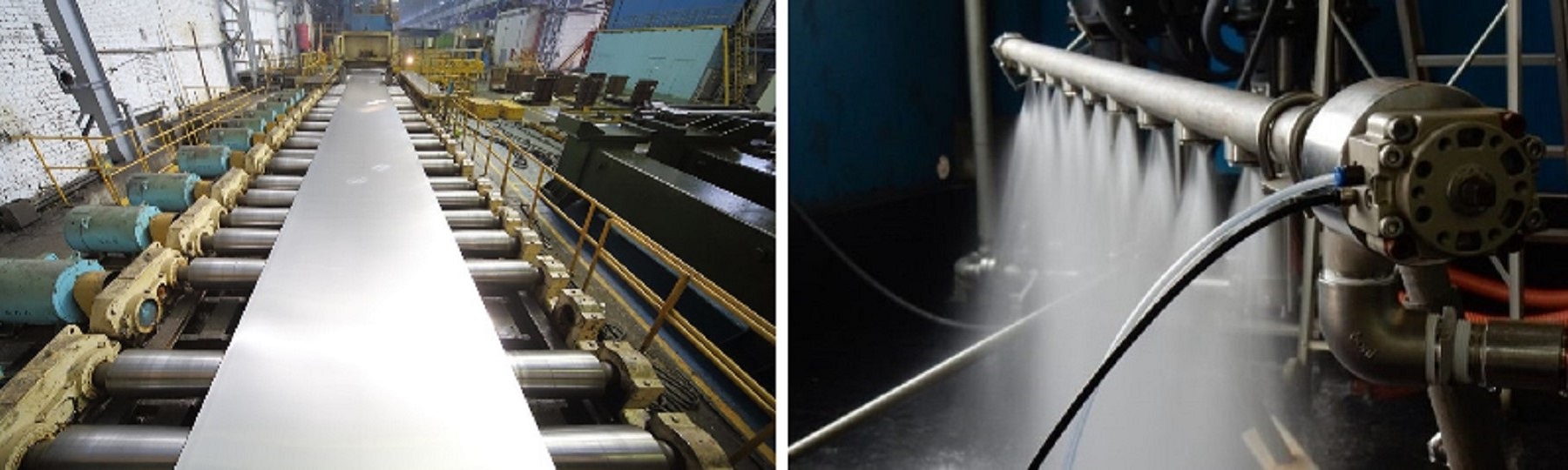

Spray Nozzle Applications in Steel Sheet Surface Treatment

Surface treatment processes for cold-rolled steel sheets in steel plants include continuous pickling lines (CPL), continuous annealing lines (CAL), and continuous galvanizing lines (CGL).

In these lines, spray nozzles are widely used for various purposes, including pickling and rinsing for scale removal, alkaline degreasing, preventing carryover of liquids to subsequent processes, and avoiding surface drying of the steel sheet.

Spray Headers

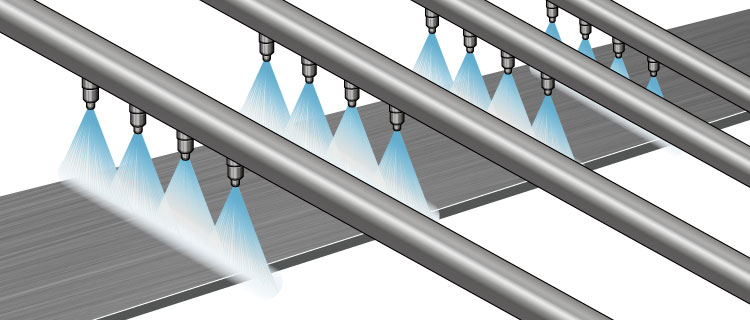

Mounting multiple spray nozzles on a single pipe and positioning it across the conveyor line is the standard method for forming a spray header that uniformly covers the full width of the steel sheet.

However, it is common to install multiple spray headers per line for supplementary coverage, with some processes employing more than ten headers in a single stage.

Maintenance Burden and Safety Risks

Using spray headers for cleaning and rinsing steel sheets typically involves recycled utility water, which often contains foreign particles that accumulate at the nozzle orifices. In chemical spraying processes, dissolved substances can precipitate and likewise lead to nozzle clogging.

Leaving nozzle clogging unaddressed results in uneven cleaning and incomplete surface treatment, leading to poor product quality and unstable spray performance, ultimately impacting the entire line.

Avoiding such risks requires periodically removing and cleaning individual nozzles from the spray headers to eliminate clogging, but with the large number of nozzles involved, this maintenance task inevitably becomes burdensome.

Spray headers are often installed in harsh environments—such as confined spaces, elevated locations, or near chemical processes—and typically exceed one meter in length. As a result, removing the headers for nozzle cleaning poses significant safety risks.

Solutions Proposed by IKEUCHI

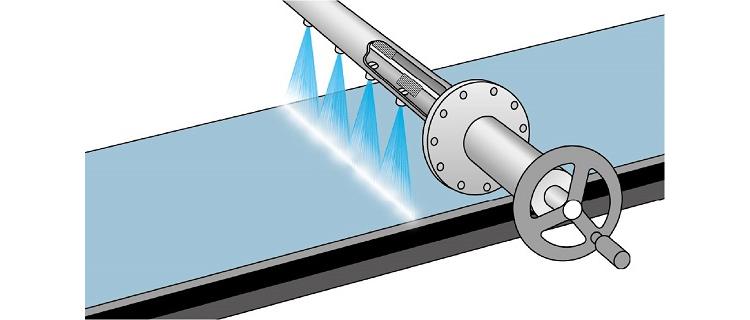

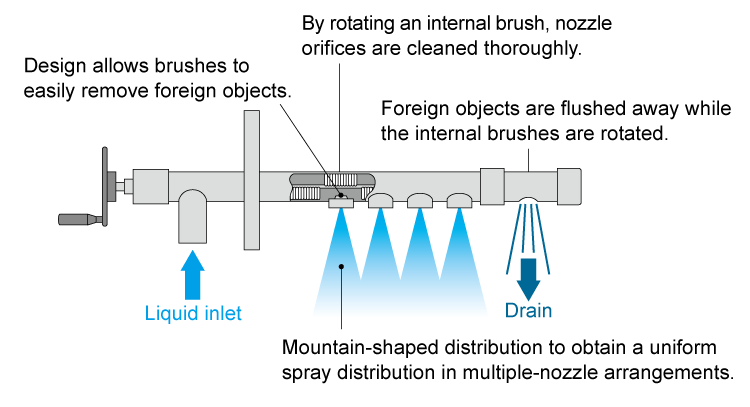

Maintaining stable line operation while significantly reducing maintenance burden and eliminating hazardous tasks—this challenge is addressed by IKEUCHI’s innovative solution: the integrated BRASIKan spray header with a foreign particle removal mechanism.

This product features an internal brush mechanism that cleans the fluid inlets of nozzles positioned inside the header. Under normal operation, it provides continuous fan-shaped spray for cleaning, rinsing, or chemical application.

When foreign particles accumulate at the nozzle fluid inlets during spraying and cause clogging, simply turning an external handle on the header rotates the internal brush mechanism to remove the particles. At the same time, a flush valve opens to discharge the removed particles through a drain.

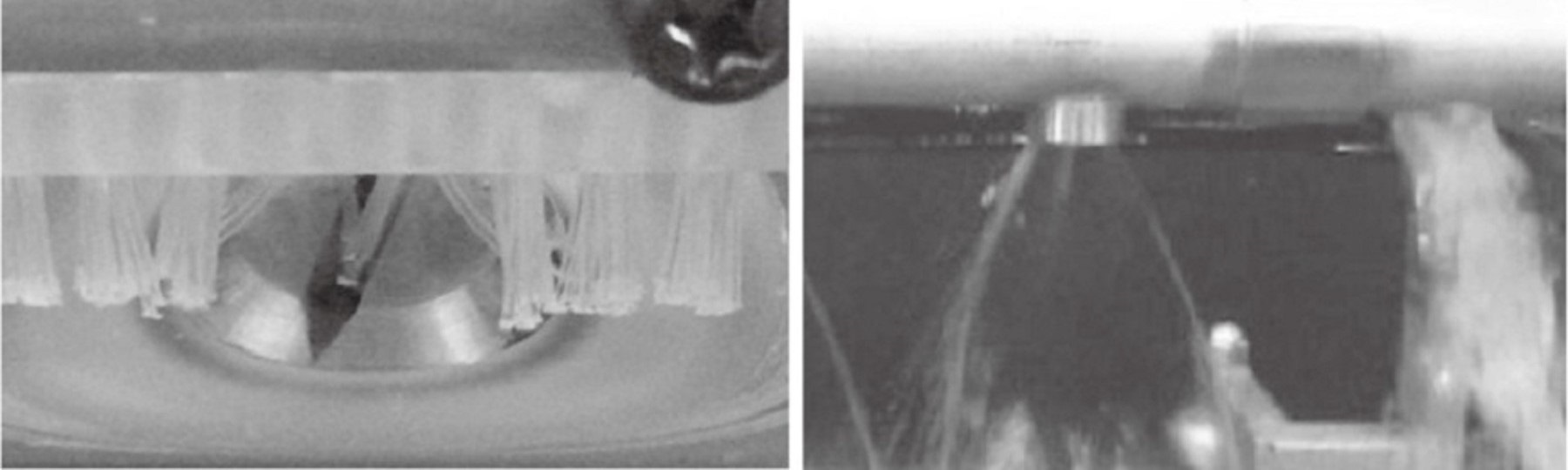

Left: Brush cleans the nozzle fluid inlet | Right: Particles discharged through the drain

The nozzles, headers, and internal brushes are all available in optional materials compatible not only with water-based rinsing but also with the spraying of acidic and alkaline solutions.

Benefits Achieved

- Simply turning the handle about three times a day completes the nozzle cleaning—freeing operators from the burdensome task of removing, cleaning, and reinstalling clogged nozzles.

- Spray headers no longer need to be removed, allowing operators to avoid hazardous maintenance tasks.

- Clogging-related issues such as uneven cleaning and surface treatment are eliminated, ensuring consistent quality of the steel sheet.

Enhanced Convenience with the Air-Driven BRASIKan

Selecting the air-driven version—capable of actuating the internal brush via a compressed air connection—enables even more hands-free operation. Its key features and implementation benefits are as follows.

- Remote brush activation enables foreign particle removal without on-site manual intervention

- Timer-based control allows for fully automated nozzle cleaning

- No manual handle required—ideal for installation in hard-to-reach or enclosed locations

IKEUCHI’s spray systems continue to support labor-saving operations and safer working environments in cold-rolled steel sheet surface treatment processes.

Air-Driven BRASIKan in action