Basics of Spray Nozzles | Classification of Spray Droplet Size

IKEUCHI sets strict acceptance criteria for spray nozzle precision, ensuring that only nozzles that meet these standards are shipped.

Even for customers with highly precise spraying requirements, our precision guarantee ensures that IKEUCHI can deliver reliable and safe products that fully meet their needs.

All precision-made hydraulic spray nozzles from IKEUCHI are guaranteed to meet specified spray angles and spray capacities (spray flow rates) at standard pressure.

This guarantee applies to metal, plastic, and ceramic nozzles.

Each pneumatic spray nozzle series also undergoes inspection for spray capacity at standard pressures. Only nozzles that meet these standards are shipped.

The information below refers to our hydraulic spray nozzles.

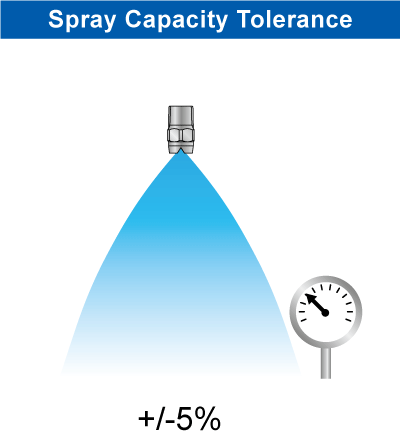

Guaranteed within ±5% of the rated spray capacity at the standard pressure* (set by nozzle series).

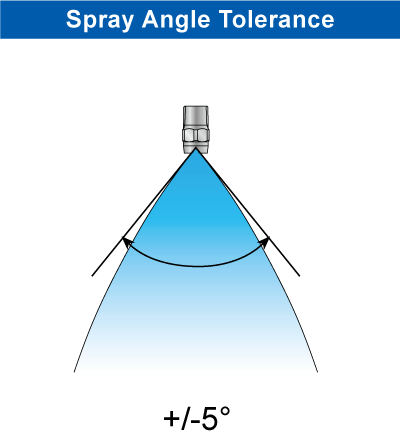

Guaranteed within ±5° of the rated spray angle at the standard pressure* (set by nozzle series).

The spray angle refers to the angle measured near the nozzle, unless otherwise specified.

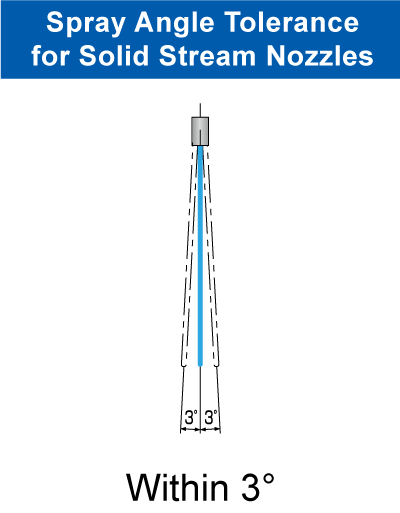

Guaranteed within 3° from the nozzle body centerline at the standard pressure* (set by nozzle series).

Spray distribution depends on various factors such as spray height, nozzle spacing, and liquid properties. However, achieving the desired spray distribution is impossible if the nozzles themselves vary in quality and performance. Without a precision guarantee, especially in multi-nozzle setups, results may be inconsistent and costly.

With IKEUCHI’s precision guarantee, you can be confident that every nozzle will meet the specified spray angle and spray capacity at standard pressure.

If a nozzle needs to be replaced, the spray performance will remain consistent.

Related Information:

Why is nozzle precision important? How can I achieve an even spray flow rate distribution with multiple nozzles?