Basics of Spray Nozzles | Classification of Spray Droplet Size

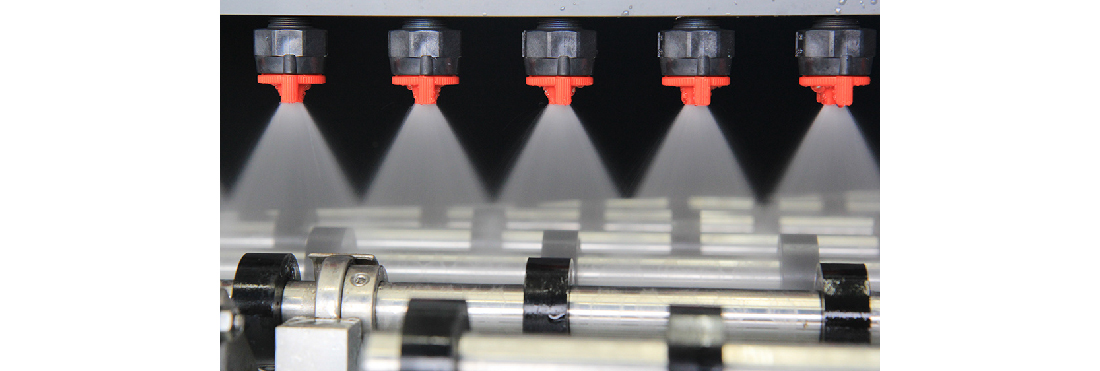

As a dedicated manufacturer of spray nozzles, IKEUCHI, The Fog Engineers, have developed a variety of nozzles made from different materials to meet our customers’ applications and requirements.

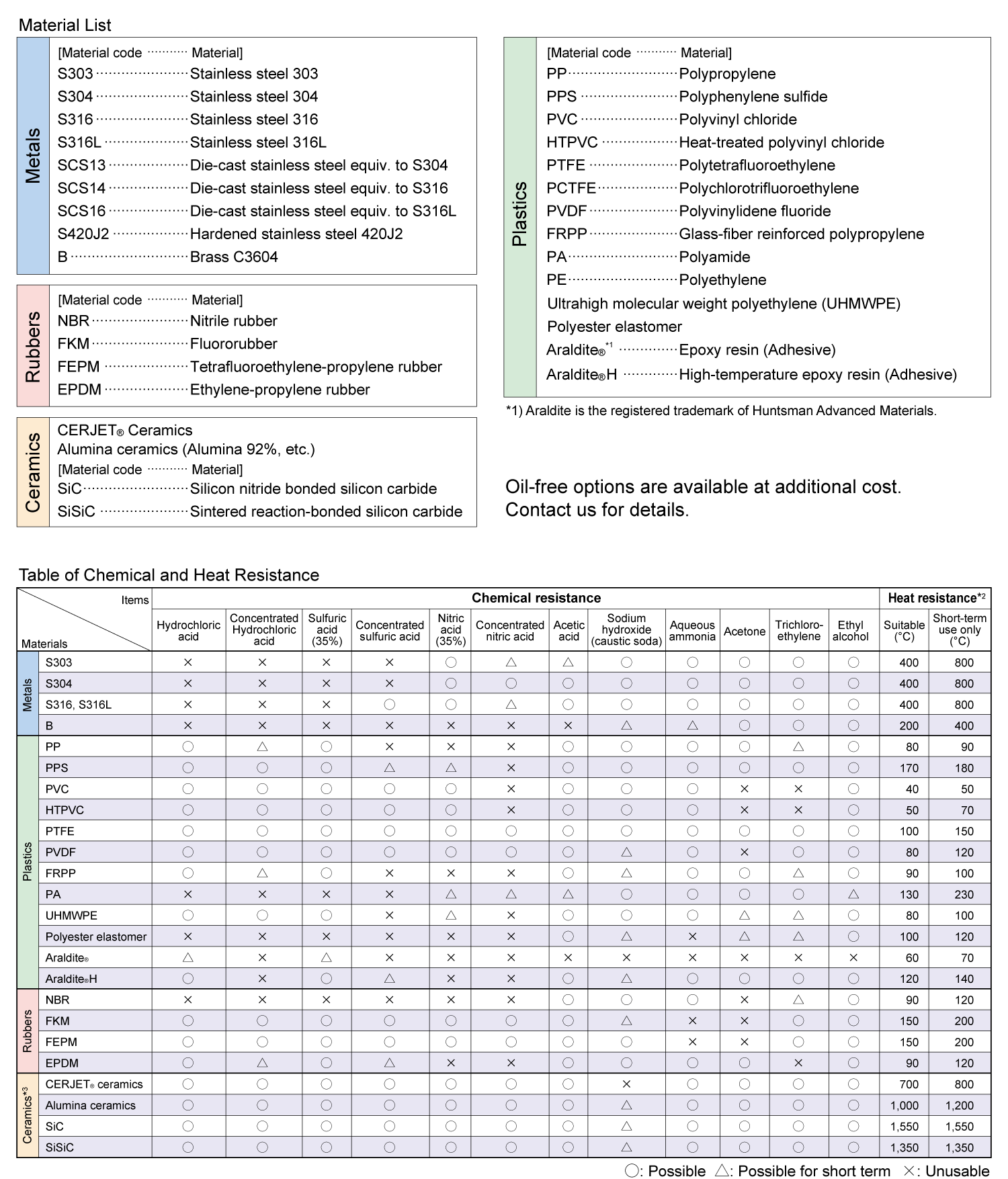

Below is a list of materials used for nozzles and components. For special applications, please contact us.

*2) The heat resistance (operating temperature limit) of spray nozzles varies widely depending on the operating conditions, environment, liquid sprayed, etc.

*3) Ceramic should be used at temperatures under 100˚C to avoid a crack caused by heat shock.

Note: For nozzles that include adhesives, consider the chemical resistance of the adhesive.

When spraying chemicals or using spray nozzles in corrosive environments, it is essential to use chemical-resistant materials to prevent deterioration of the nozzles. Our standard nozzle materials include stainless steel 303, brass, and plastic, with some series featuring a ceramic orifice (CERJET®).

The CERJET is a metal nozzle primarily made of stainless steel 303 with a ceramic orifice. This ceramic orifice offers exceptional resistance to wear and chemicals, and it withstands most acids and highly corrosive substances, except for hydrofluoric acid and alkali liquids with a pH of 12 or higher.

The CERJET includes several product series, such as the VP Series flat spray nozzles, the KB Series hollow cone spray nozzles, and the CP Series solid stream spray nozzles.

For more information, please contact us with your specific application needs and requirements.

However, because the epoxy resin adhesive is used to bond the ceramic orifices to the metal body, in applications where the adhesive or the metal nozzle body may be corroded, we recommend using the CERTIIM® nozzle, which features an engineered plastic body molded around a ceramic orifice, as it provides exceptional chemical resistance.

The CERTIIM is available in VP and VEP Series (VP-TPVDF and VEP-TPVDF).

In addition to our standard materials, nozzles in optional or special materials are available on a made-to-order basis.

The temperature a spray nozzle can withstand varies greatly depending on the environmental conditions and the properties of the spray liquid.

For nozzles including adhesives it is important to also consider the heat resistance of the adhesive.

The ceramic tips of CERJET® will crack if abruptly cooled down from high temperatures (200°C).

Alumina ceramics will crack due to temperature changes of 100°C or more.

Nozzle tips and orifices are constantly subjected to the flow of high speed liquid exposing them to wear. If the liquid is circulated and re-used, slurry and other dirt particles will enter, wearing tips and orifices out even faster.

Increased wear will narrow the spray angle of a flat spray nozzle and worsen its spray distribution.

In hollow cone spray nozzles, an air core is generated in the center of a vortex. This can cause wear at the tip of the air core, especially if the spraying liquid contains slurry or the like.

The ceramic orifice of CERJET spray nozzle has an outstanding wear-resistance, with a hardness of 7 on the Mohs scale. It can last 20–30 times longer than stainless steel nozzles and several hundred times longer than brass ones.

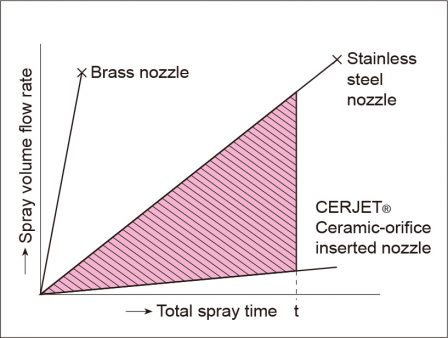

| The figure shows the increase in flow for each nozzle due to worn orifices.

The shaded area indicates the excess spray flow from a stainless steel nozzle relative to a CERJET® during the same spray time (t). The CERJET is recommended for applications requiring wear-resistant nozzles, including high-pressure cleaning and for use with liquids containing slurry. |

|