Air-liquid Mixing Systems

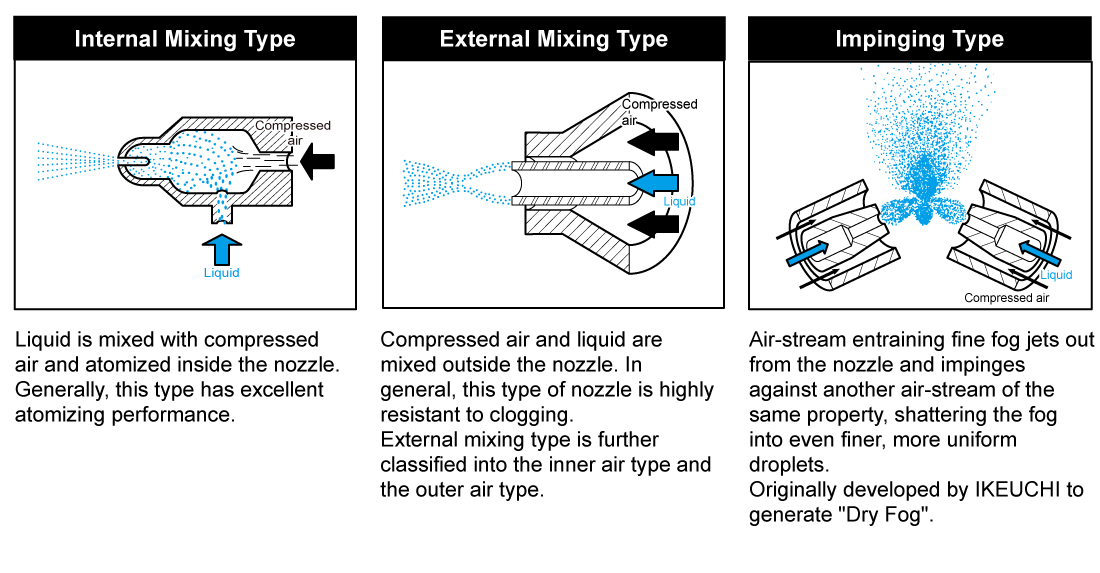

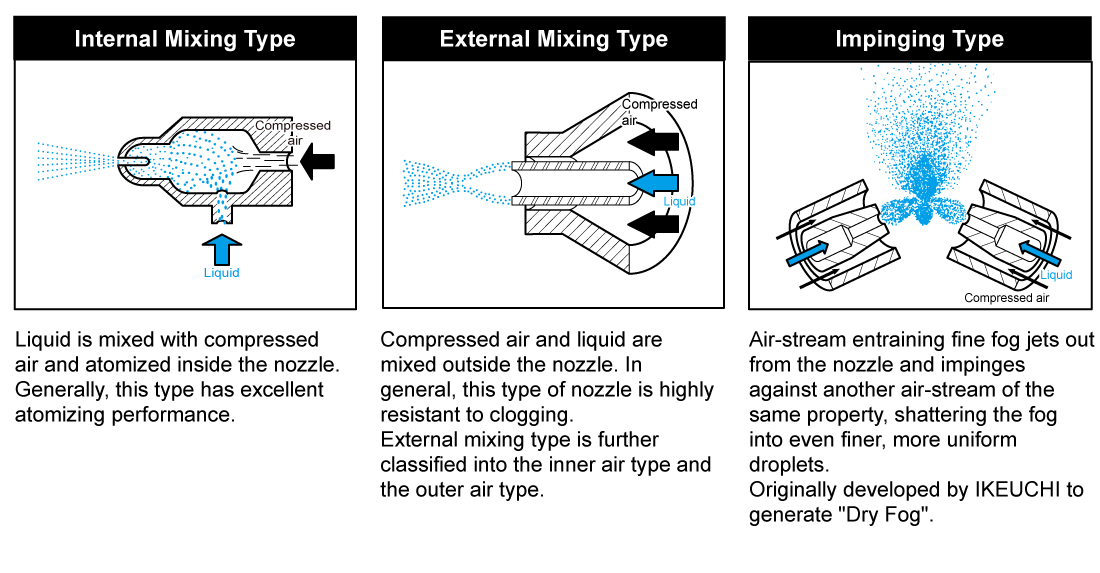

There are three types of pneumatic nozzles, based on different methods of mixing liquid with compressed air for atomizing it.

Internal Mixing Type is further classified into the following three types.

Inner air type

Inside the nozzle, compressed air flows in the center while liquid flows along its circumference.

Its larger liquid passage diameter effectively prevents clogs.

Outer air type

Inside the nozzle, liquid flows in the center while compressed air flows along its circumference.

This common type can have a larger orifice size, resulting in slightly coarser spray droplet sizes.

Pre-mix type

Air and liquid mix before reaching the orifice. Even at low air-water ratios, droplet velocity accelerates prior to the orifice, resulting in a stronger impact force.

Additionally, this nozzle type has a larger turn-down ratio, making it suitable for cooling objects at high temperatures.

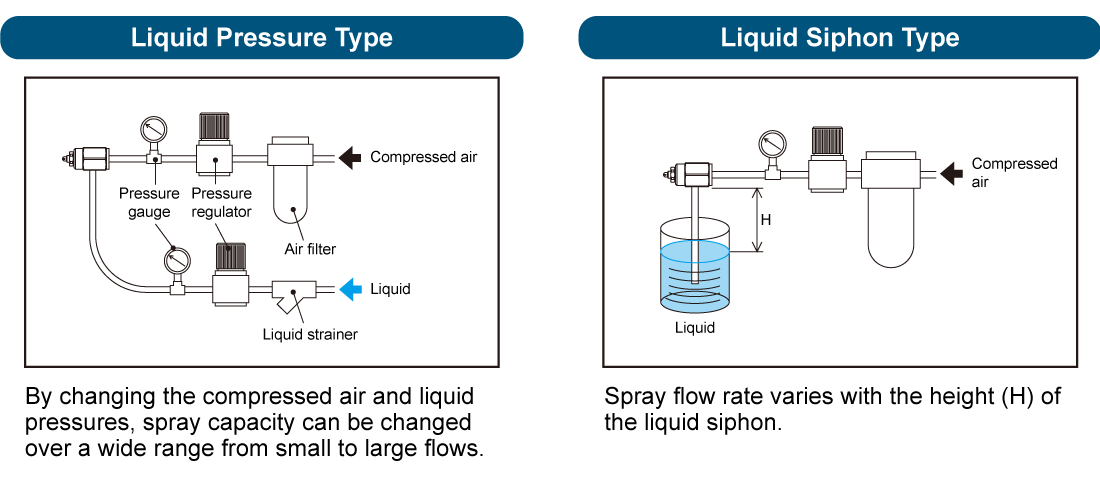

Liquid Feeding System

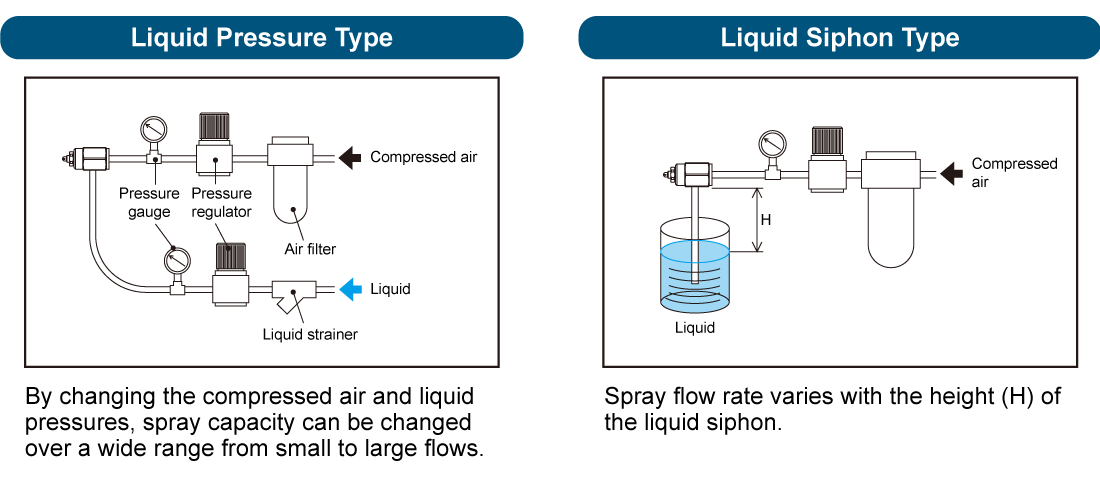

There are two types of liquid feeding systems: the liquid pressure type (where liquid is pressurized and delivered to the nozzle) and the liquid siphon type (where liquid is sucked up into the nozzle by compressed air).

For your information, some of our pneumatic spray nozzle series are available in both the liquid pressure type and the liquid siphon type, including the BIMV, BIMV-S series and BIMK, BIMK-S series.