Technical Library

- HOME

- Technical Library

- Spray Nozzle Maintenance for Dry Fog Humidifier AKIMist®E

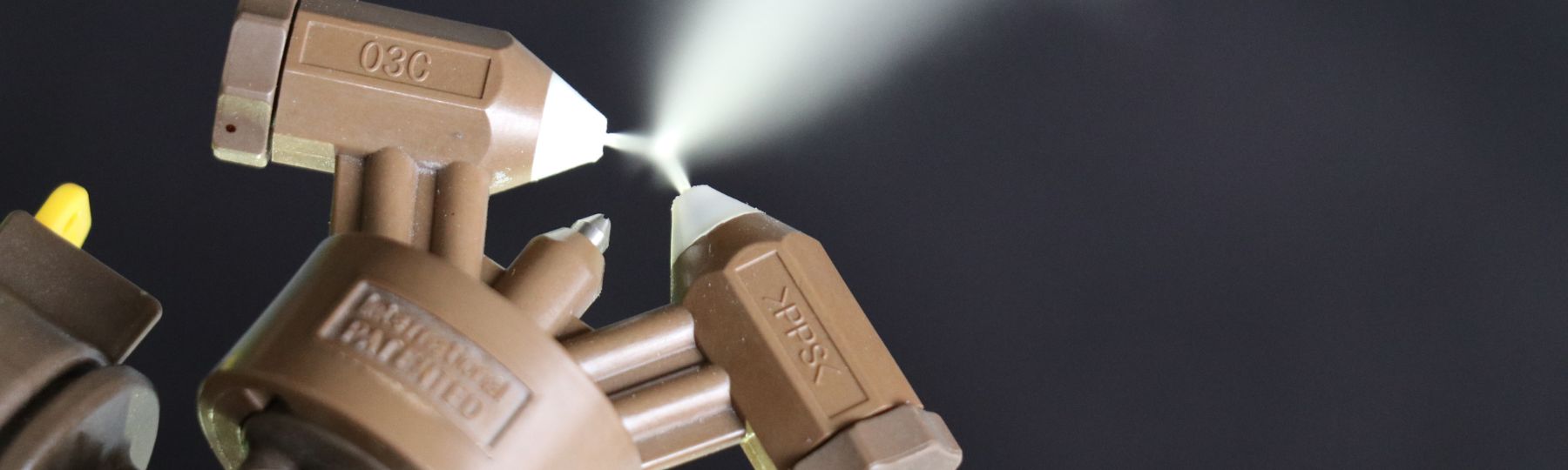

Spray Nozzle Maintenance for Dry Fog Humidifier AKIMist®E

Intro

Even the most luxurious items require a little TLC so it’s no surprise that our high-quality spray nozzles require the occasional maintenance. Proper care for your spray nozzle will optimize performance capabilities and lifespan. Who knew a little cleaning could save you so much time and money?

8 Steps to a Clean Spray Nozzle

We’ve broken down the cleaning process into 8 simple steps.

1. Gather Materials:

You will need warm water, a small bowl/container, mild dish soap or a suitable cleaning solution, a soft brush/toothbrush, and a clean cloth. It’s crucial to use a non-corrosion cleaning agent.

2. Remove The Nozzle:

If possible, detach the spray nozzle from the bottle/sprayer; this allows for easier, and more thorough cleaning.

3. Rinse With Warm Water:

To loosen any clogs or build-up, hold the nozzle under warm running water.

4. Soak In Cleaning Solution:

Grab your bowl/small container with the mixture of warm water and mild dish soap (or suitable cleaning solution). To get rid of stubborn residue, let the nozzle soak in the solution for 10-15 minutes.

5. Scrub The Nozzle:

Once the 10–15-minute soak is up, take the soft brush/toothbrush and gently scrub the nozzle. It’s important to note that excessive force or using a material that isn’t soft can damage the nozzle. Also, make sure to get all the openings and crevices for a thorough clean.

6. Rinse:

Bring the nozzle under warm running water once again and remove the cleaning solution and debris.

7. Dry:

Use a clean cloth to pat dry or air dry before reattaching the nozzle. Make sure that it is completely dry before reassembling.

8. Test:

Now you can test the reassembled nozzle and test if the spray is coming out as it should and there are no residual blockages.

Follow-up Testing

Here are some things to look out for when testing:

- Inspect for damages

- Check the alignment

- Check the spray pattern

- Inspect the flow rate

When to Consider Replacement Nozzles

Though our nozzles are built to last, with consistent use there will come a time to consider replacing. If you notice the following signs even after thorough cleaning, it may point to needing a replacement.

1. Poor Spray Pattern:

If the spray pattern is uneven, inconsistent, or has become distorted, it could indicate wear or damage to the nozzle. This can affect the efficiency and effectiveness of the spray.

2. Clogging or Blockage:

If the nozzle frequently clogs or gets blocked, it could be a sign of nozzle deterioration. Over time, nozzles can develop internal deposits or corrosion that impede proper flow.

3. Leaking or Dripping:

If the nozzle is leaking or dripping even when not in use, it could indicate a worn-out seal or damage to the nozzle. This can result in wasted product and reduced spraying accuracy.

4. Physical Damage:

Check the nozzle for any visible signs of damage such as cracks, breaks, or significant wear. Physical damage can affect the spray pattern, flow, and overall performance of the nozzle.

5. Excessive Wear & Tear:

With regular use, spray nozzles can wear down over time. If you notice flattened or deformed spray orifices, it may be an indication that the nozzle needs to be replaced.

6. Reduced Performance:

If you observe a significant decrease or change in spray distance, coverage, or overall performance compared to when the nozzle was new, it may need replacing.

Want an Even Longer Lasting Solution?

Try our ceramic nozzles- ceramic has a longer lifespan

- Higher wear resistance

- Higher chemical resistance

- Higher temperature resistance

- More rigid

Access the Ikeuchi USA LinkedIn Newsletter Article Here: Spray Nozzle Maintenance

- Not sure which product is right for you?

- Curious about the total cost?

- Wondering where to start?

- We’re here to help – reach out with any questions.