Gas Turbine Inlet Air Cooling System | Boost Power and Ensure Stable Supply

Gas turbines are essential to power generation, aviation, and industrial applications, but they are not immune to environmental challenges. One of the most significant threats to their efficiency and longevity is heat—specifically, high ambient temperatures. As global temperatures rise and demand for reliable energy increases, finding effective cooling solutions has never been more critical.

Among the most advanced and efficient methods available today is semi-dry fog cooling. But why is heat such a problem for gas turbines, and how does semi-dry fog provide the solution?

Gas turbines operate based on the principle that higher air density improves combustion efficiency and power output. However, hotter air is less dense, meaning gas turbines must work harder to generate the same level of output. The key challenges include:

1. Reduced Power Output

When the ambient temperature rises, the mass flow rate of air entering the compressor decreases, leading to lower power output. Studies show that for every 1°C (1.8°F) increase in temperature, gas turbine efficiency can drop by 0.5% to 1%. This loss can be significant in peak summer months when electricity demand is at its highest.

2. Increased Fuel Consumption

To compensate for reduced air density, gas turbines must burn more fuel to maintain performance. This not only increases operational costs but also raises greenhouse gas emissions, making operations less environmentally sustainable.

3. Higher Maintenance Costs

Excess heat can accelerate component wear and tear, leading to more frequent maintenance, unplanned downtime, and higher overall operating expenses. The compressor, combustor, and turbine blades are particularly vulnerable to thermal stress.

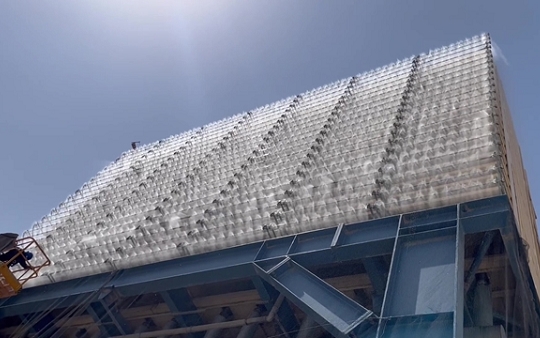

To counteract the effects of heat, semi-dry fog cooling has emerged as one of the most effective solutions. Unlike traditional water mist or wet fog systems, semi-dry fog provides ultra-fine water droplets (below 10 microns in size) that evaporate quickly, cooling the surrounding air without wetting surfaces.

As industries strive for higher efficiency and sustainability, semi-dry fog cooling is becoming a critical tool in maximizing gas turbine performance. Whether in power plants, industrial operations, or aviation, this technology helps operators overcome heat-related challenges without compromising reliability.

Heat poses a major challenge to gas turbines, but semi-dry fog cooling offers a smart, energy-efficient solution. By improving air density, reducing fuel consumption, and protecting critical components, this technology ensures turbines can operate at peak performance—even in the hottest climates.

To stay ahead in power generation and industrial efficiency, embracing advanced cooling solutions like semi-dry fog is no longer optional—it’s essential.