Full Cone Spray Nozzles (Alumina Ceramic) AJP-AL92

Hydraulic hollow cone spray nozzles, featuring a tangential des…

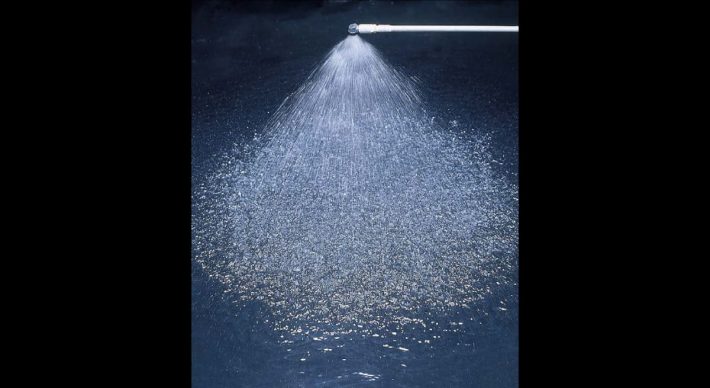

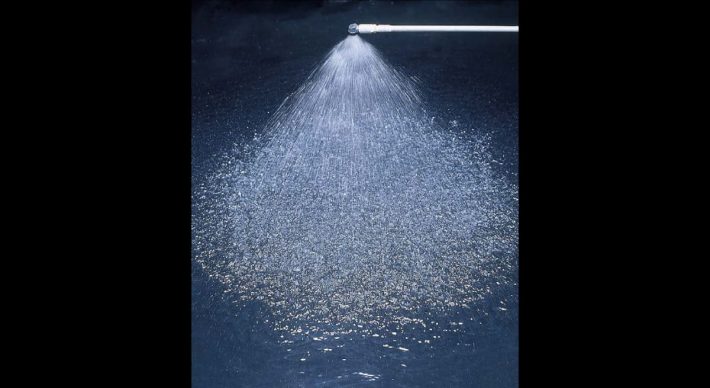

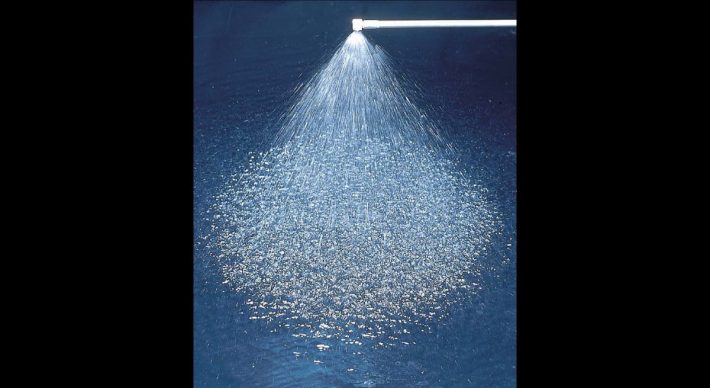

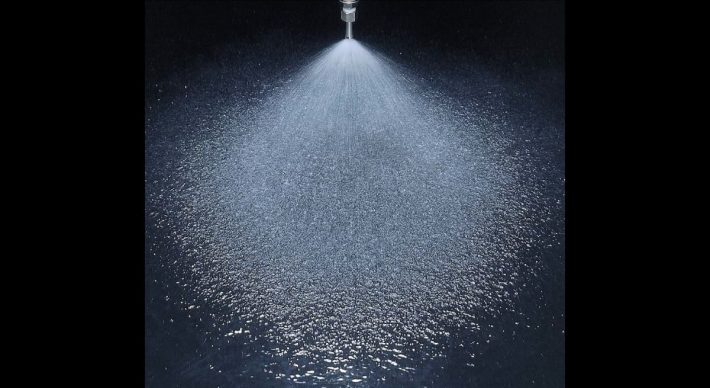

Full Cone Spray Nozzles (Clog-resistant)

Hydraulic full cone spray nozzles, featuring a tangential design with the spraying axis at a 90˚ angle from the nozzle inlet. Their design without a whirler allows for a large free passage diameter.

| Liquid Inlet Thread Size | R1/8–R1*1/2 |

|---|---|

| Main Material | S303, S304, SCS13 |

| Spray Droplet Measuring Method | Immersion sampling method |

| Mean Droplet Diameter | 640–1,400 μm |

| Standard Pressure | 0.2 MPa |

| Spray Capacity (Flow-rate) at Standard Pressure | 2.00–250 L/min |

| Spray Angle at Standard Pressure | 75º, 80º, 85º, 90º |

Materials: Click here for full material descriptions, including chemical and heat resistance.

CAUTIONS FOR USE (Sizes R1/8, R3/8, and R1/2):

In extreme high or freezing temperatures, the AJP press-fitted orifice cap for sizes R1/8, R3/8 and R1/2 may come off. For these conditions, order the AJP nozzles in S316 with the screw-in orifice caps. Do not use AJP size R1/8 in these conditions, the screw-in orifice cap is not available for size R1/8.

• Full cone spray pattern with a round impact area and uniform distribution.

• Unique design to produce fine atomization by liquid impinging inside chamber without a whirler.

• No-whirler design with large free passage diameter minimizes clogging.

• Spraying axis 90゚ from the axis of the nozzle inlet.

• High chemical and wear resistant AJP-PPS series is available for spraying hydrochloric acid and other chemicals.

Hydraulic hollow cone spray nozzles, featuring a tangential des…

Hydraulic full cone spray nozzles, featuring a tangential desig…

Hydraulic full cone spray nozzles with a round-shaped spray are…