Automating Fermentation Tank Cleaning with 3D Rotating Nozzles to Solve Labor Shortages

Solutions or Products Featured

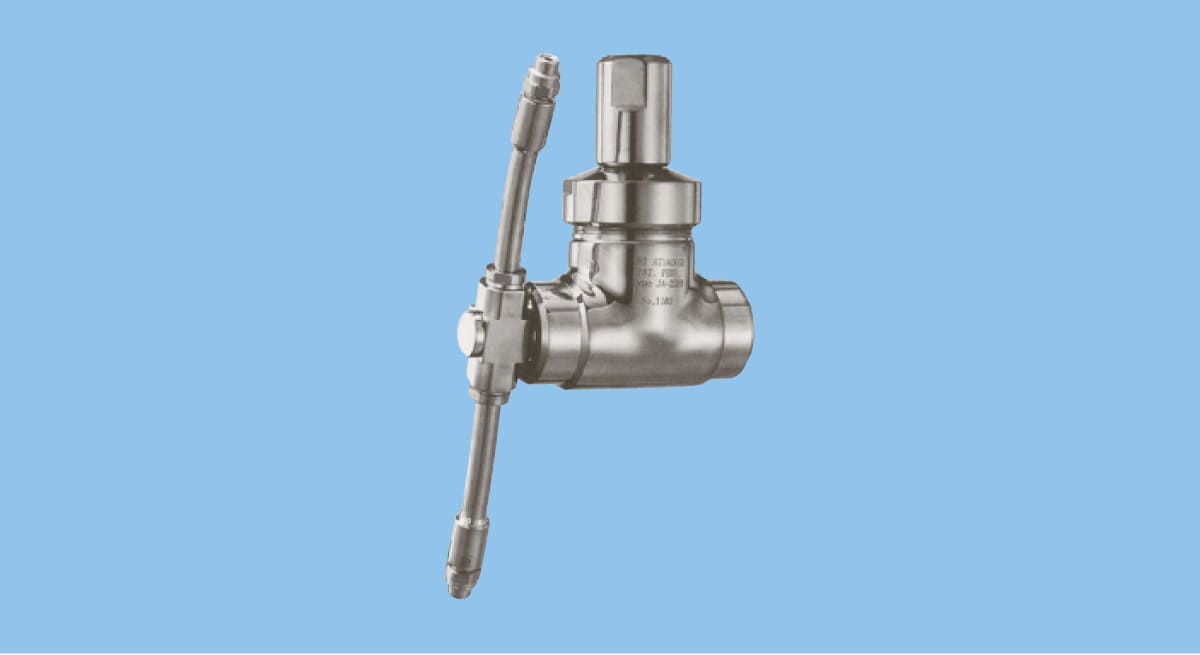

in This Case Study

At a liquor brewing facility, operators were manually cleaning brewing tanks measuring 4 meters in diameter and 5 meters in height with a high-pressure washer every day. The facility housed 20 identical tanks, with 3 to 4 being cleaned daily on a rotating schedule, each requiring approximately 30 minutes. Additionally, the cleaning process involved working from the top of the tall tanks, creating significant safety risks.

To address these challenges, the customer sought ways to streamline operations through automated cleaning and improve safety by avoiding hazardous tasks. In this process, they consulted IKEUCHI for assistance in selecting a suitable tank cleaning nozzle.

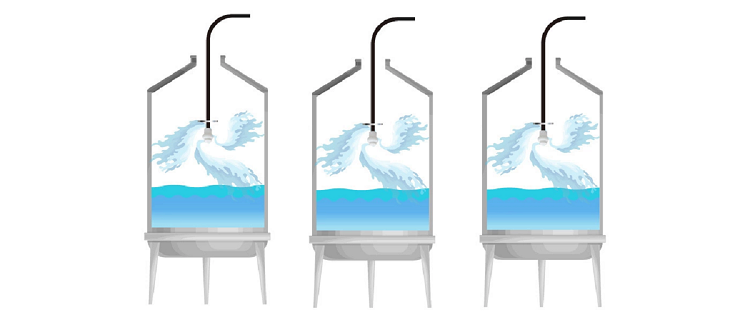

An inspection of the site and utility setup revealed that a pump with a discharge pressure of 1.0 MPa was available. Based on this, we selected and proposed a 3D rotating tank cleaning nozzle capable of automatically and thoroughly cleaning the tank’s interior surfaces when connected to the pump.

A cleaning test was conducted using a demonstration unit, and the results confirmed its effectiveness.

Automating the cleaning process removed the need for a dedicated operator to spend 1.5 to 2 hours daily on the task, allowing that time to be reallocated to other duties. Simultaneously, hazardous high-altitude work was avoided, significantly enhancing workplace safety.

The brewery now plans to expand this solution to other facilities with similar processes.