Different Humidification & Installation Methods | Types of Humidification | Premium Dry Fog

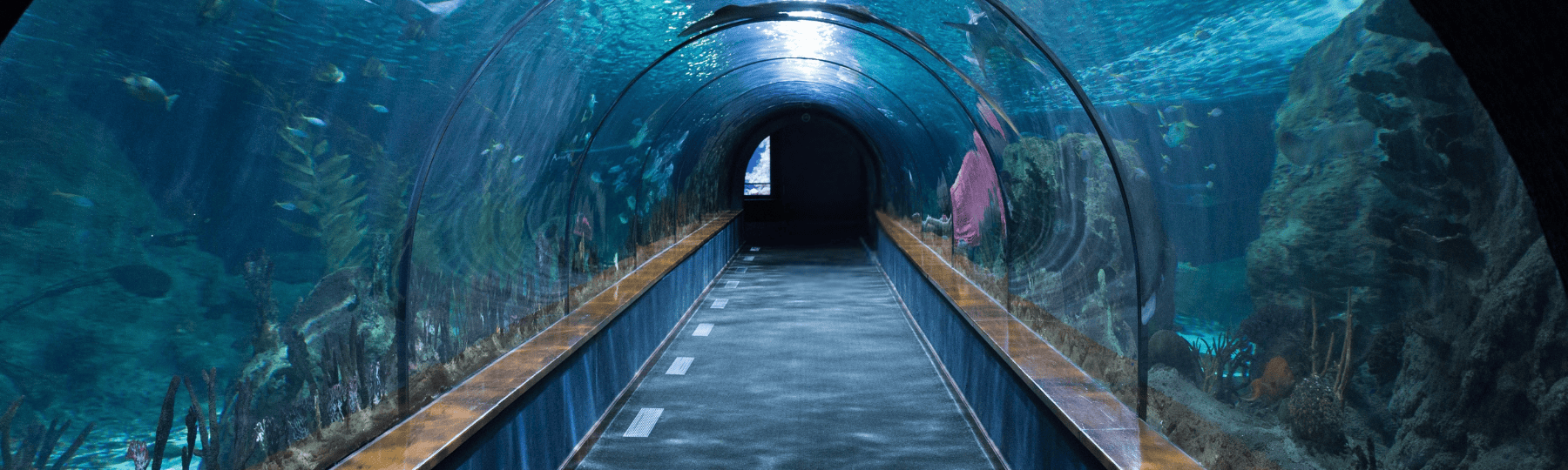

Controlling humidity across a multi-functional facility is a lot like managing an aquarium filled with different species. Some require warmer water, others need it cooler. Some thrive in high-oxygen environments, while others prefer less. If you treat the entire tank the same, something will be out of balance. Humidity works the same way. From production lines to storage areas to sensitive workstations, each zone may require different conditions to perform at its best. Zoning makes it possible to meet those needs precisely, without overuse or unnecessary adjustments.

Uniform humidity is essential in many controlled environments. For example, cleanrooms, archival storage, and some manufacturing operations rely on consistency throughout the space to maintain strict quality standards.

Still, there are plenty of environments where needs vary zone to zone. Treating the entire space the same way in these cases can lead to inefficiencies, like:

For facilities with diverse workflows, products, or plant stages, targeted humidity control offers flexibility that standard whole-room approaches may not.

Zoning humidity means delivering targeted relative humidity levels to specific parts of a facility rather than trying to control the entire space uniformly. This is especially useful in spaces where environmental needs shift based on product, location, or function.

Dry fog humidification systems are particularly well suited for this. By generating ultra-fine droplets that evaporate instantly, they can raise humidity in specific zones without soaking surfaces or impacting nearby areas. This precision makes them ideal for microclimate creation.

For example:

One of the key advantages of Ikeuchi’s humidity control system is the modularity. As facilities expand or operations change, the system can scale accordingly. New zones can be added, existing ones adjusted, and overall performance optimized without replacing the entire setup.

This adaptability ensures that humidity control continues to match operational needs, whether those needs are uniform or varied across different zones.

Zoning can also improve sustainability. By focusing resources only where needed, facilities reduce water and energy consumption. Additionally, microclimates help avoid common pitfalls like condensation, corrosion, or microbial growth that can result from over-humidification.

And when uniform humidity is still the best approach, the same dry fog systems can handle it with precision and minimal waste.

Whether your facility requires consistent humidity throughout or tailored conditions for different zones, the key is control. Understanding when and where to apply uniformity versus customization leads to better performance, fewer issues, and more efficient operations.

Smart, adaptable humidification strategies, especially those using dry fog, offer a flexible solution for today’s evolving production environments.