Article by Industry: Automotive | Controlled Environment Manufacturing | Dry Fog Dust Suppression

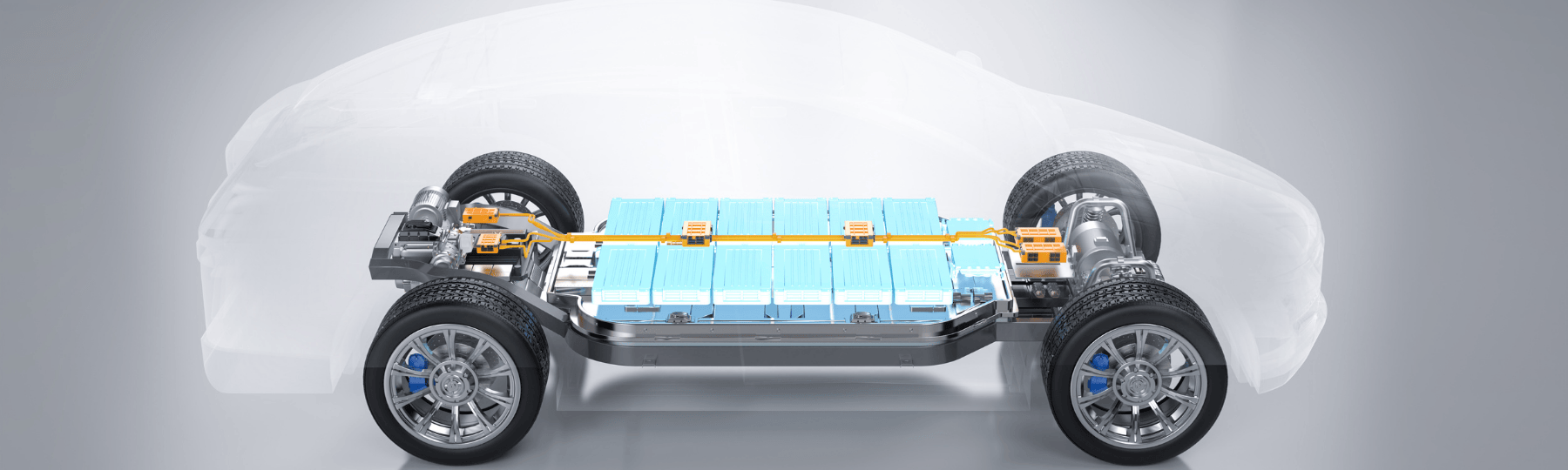

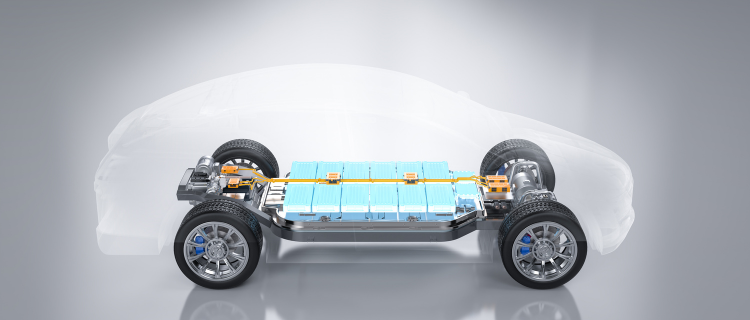

Electric vehicle batteries are the heart of modern mobility, but even the most advanced chemistry can fail if the production environment is not precisely controlled. Tiny fluctuations in humidity, airborne particles, or electrostatic charge can create defects that compromise safety, performance, and longevity. For manufacturers, creating a stable, contamination-free environment is no longer optional. It is the foundation for producing batteries that meet the exacting standards of today’s EV market.

Humidity might seem like a small factor, but in sensitive production environments, it can be a decisive one. When air is too dry, static electricity builds on surfaces and components, increasing the risk of electrostatic discharge (ESD). Even minor discharges can damage delicate materials or disrupt production processes. On the other hand, too much moisture can lead to condensation, corrosion, or contamination. Industry standards such as ANSI/ESD S20.20 and ISO cleanroom guidelines emphasize maintaining relative humidity within a precise range, typically 40% to 60%, to balance these risks. Controlling humidity with accuracy protects components, ensures consistent manufacturing conditions, and reduces costly defects.

AKIMist®E Dry Fog humidifiers have set the standard in industries where precision is non-negotiable. Semiconductor fabrication, surface-mount technology (SMT) assembly, and electronics manufacturing all rely on AKIMist®E to maintain optimal humidity without wetting sensitive equipment. The ultra-fine mist delivers stable relative humidity with tight tolerances, reducing static buildup and minimizing contamination. Companies that use AKIMist®E report measurable benefits, including higher product yield, reduced downtime, and more reliable production processes. This track record demonstrates that the technology is not only effective but also adaptable to other high-precision manufacturing environments.

EV battery manufacturing shares many of the same challenges faced by electronics and semiconductor production. Sensitive components are vulnerable to static and contamination, and even minor variations in environmental conditions can lead to defects or failure. By applying the same humidity control principles, battery manufacturers can mitigate these risks. Maintaining stable relative humidity reduces electrostatic charge, protects materials, and ensures that every battery cell or module meets rigorous quality standards. Lessons learned from high-tech industries can be directly applied to the next generation of EV battery production.

Dry Fog has proven its value in high-precision manufacturing worldwide, and its benefits extend naturally to EV battery production. By creating consistent, controlled environments, manufacturers can improve safety, enhance reliability, and reduce waste. As the demand for high-quality EV batteries continues to rise, integrating trusted humidity control solutions like AKIMist®E will help producers meet performance expectations and deliver products with confidence. For industries where precision and consistency matter, AKIMist® E demonstrates that effective environmental control is a key factor in success.