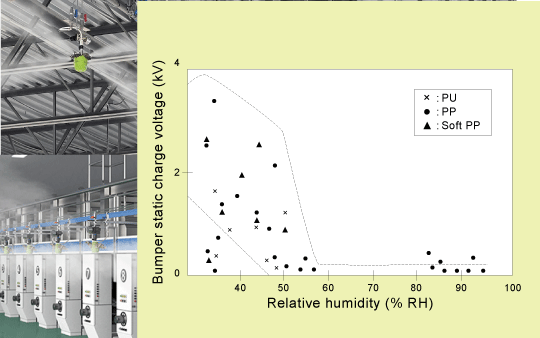

Absolute and Relative Humidity: The Relationship with Static Charge

In textile manufacturing, static and dust are not minor inconveniences. They cause thread breakage, slow production, attract contaminants to fabrics, and create extra cleaning work. Controlling humidity is one of the most effective ways to combat these problems. The AKIMist® “E” Dry Fog Humidifier offers an efficient way to do it without wetting fabrics or equipment.

Low humidity causes fibers to lose moisture. This makes them stiff and fragile, leading to more thread snapping, machine stoppages, and inconsistent product quality.

Dry air encourages static electricity to form on fibers. This static makes fibers cling to machinery or to each other and can discharge unexpectedly, damaging products or equipment.

Dust and lint in the air settle on fibers and machines. Static makes the problem worse by attracting airborne particles to fabrics, rollers, and guides. This increases the need for cleaning and can spoil finished goods.

Dry environments are also uncomfortable for workers and can irritate airways. Stable humidity creates a healthier environment.

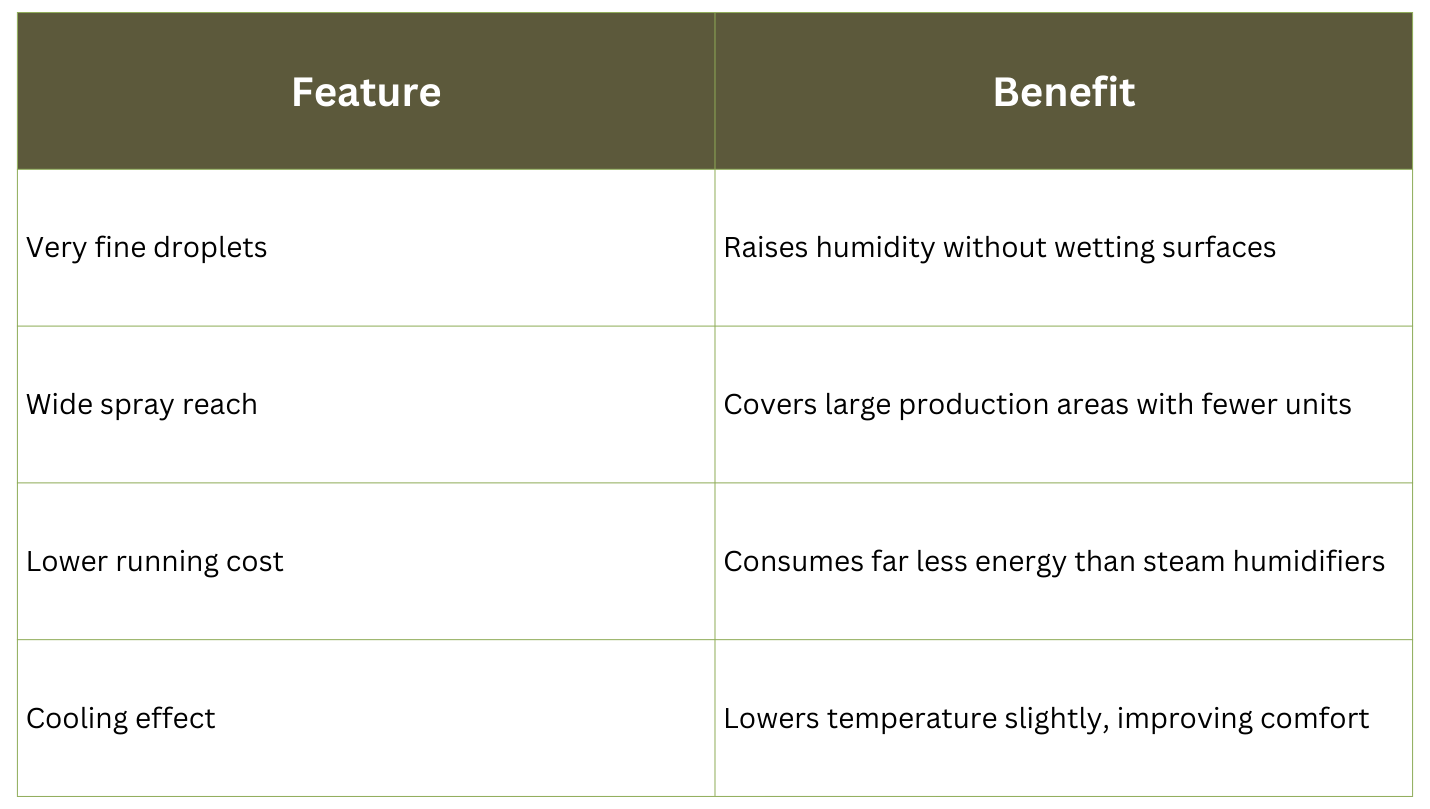

AKIMist “E” produces extremely fine droplets, small enough to evaporate quickly in the air. This raises humidity levels without wetting fabrics or equipment, even near the nozzles.

By maintaining relative humidity in the recommended range for textiles, static charges dissipate naturally. Fibers retain a slight amount of moisture, making them less likely to accumulate charge.

A slightly more humid environment makes airborne particles heavier so they settle more easily and do not cling to fibers. Less static also means less attraction of dust to fabrics and machinery.

Compared to steam humidifiers, AKIMist “E” runs at a fraction of the cost and also provides a mild cooling effect that helps keep production areas comfortable.

On weaving floors processing cotton, polyester, or blends, AKIMist “E” reduces thread breakage and lint buildup on guides and rollers.

Synthetic fiber spinning often produces static that causes tangling or sticking to machinery. Controlled humidity with AKIMist “E” keeps fibers manageable and lowers waste.

During finishing processes, static attracts dust and misaligns fabric layers. Dry fog humidification helps ensure accurate cuts and a cleaner product appearance.

Implementing AKIMist “E” in textile plants can result in fewer defects, reduced downtime for cleaning, lower energy costs, improved product consistency, and a more comfortable working environment. By tackling static and dust at the source, manufacturers can raise quality and productivity simultaneously.

Static and dust undermine productivity and product quality in textile manufacturing. The AKIMist® “E” Dry Fog Humidifier provides a reliable way to control humidity without wetting fabrics, reducing both static and dust while cutting energy costs. For textile plants that want smoother production and better quality, improving the air can make all the difference.