Supporting Wood-Ear Mushroom Cultivation with Dry Fog Humidifiers and Precision Spray Nozzles

Solutions or Products Featured

in This Case Study

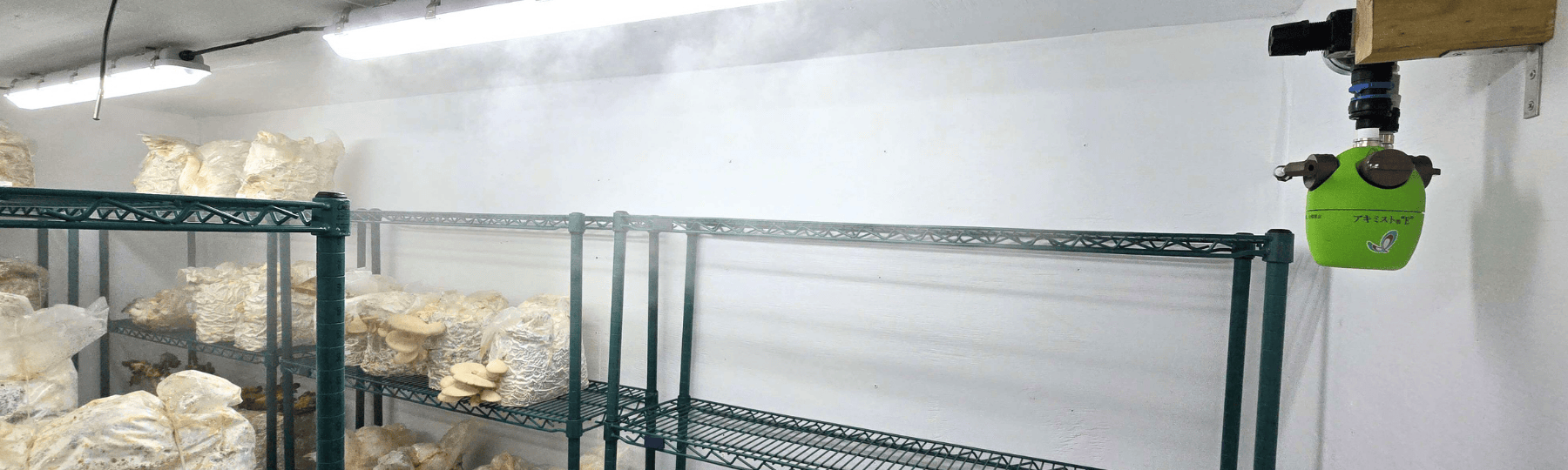

Indoor mushroom cultivation is a constant balancing act. Humidity, temperature, air exchange, and sanitation must all work together to create a stable growing environment. When production takes place in enclosed spaces with high air turnover, even small lapses in humidity control can quickly affect crop health, yield, and contamination risk.

FreeSol Farms operates in exactly this kind of environment. In a recent interview, founder Jacob Purcell shared how maintaining consistent humidity became a turning point for his operation and why dry fog technology now plays an essential role in his cultivation process.

FreeSol Farms is a small-scale gourmet mushroom operation based in Texas. The farm produces oyster, lion’s mane, maitake, and other specialty mushrooms, supplying local restaurants and markets with approximately 50 to 100 pounds per week, with the ability to scale higher.

The entire operation runs out of a converted three-and-a-half-car garage. While compact, the space is highly controlled. Environmental consistency is essential, as even minor deviations can affect crop quality or trigger contamination.

Jacob’s path to mushroom cultivation began after graduating from Texas A&M in 2019. His original focus was market gardening, growing high-value crops on small plots. That changed after an unexpected opportunity.

“I followed a few growers online, and they ran a giveaway for a trip to a mushroom operation in British Columbia,” Jacob said. “I bought a t-shirt and ended up winning. Visiting that farm completely changed my outlook.”

Inspired by what he saw, Jacob pivoted to mushrooms and began building his own operation. Early years included setbacks related to contamination and environmental control, which pushed him to refine his systems and processes.

Mushrooms thrive in conditions similar to those found after rainfall. FreeSol Farms maintains humidity between 80 and 90 percent and temperatures between 50 and 65 degrees Fahrenheit. At the same time, the grow rooms require high air exchange to provide sufficient oxygen.

This combination creates a challenge. High airflow rapidly dries the space, and any inconsistency in humidity can stall growth or damage developing mushrooms.

“Mushrooms need extremely high humidity, but you also have to keep surfaces dry,” Jacob explained. “Too wet and you create ideal conditions for pathogens. Too dry and growth stops.”

Contamination is a constant concern. Jacob described it as the number one problem mushroom growers face, especially in enclosed environments where moisture is not carefully controlled.

Before switching to dry fog, FreeSol Farms relied on ultrasonic humidifiers and DIY misting solutions.

“With ultrasonics, you’re dealing with standing water and vibrating discs,” Jacob said. “That water becomes contaminated quickly, and then you’re atomizing those contaminants into the grow room. On top of that, the droplets are large enough to wet the mushrooms and surfaces.”

Wet surfaces increased the risk of contamination and required constant cleaning. Equipment failures and frequent replacement added to both labor and cost.

The Ikeuchi AKIMist®E system uses an air-assisted nozzle to generate an ultra-fine dry fog. The droplets evaporate before settling, increasing humidity without surface wetting and without relying on a standing water reservoir.

“It’s plug and play,” Jacob said. “You connect water and air, and it delivers consistent humidity without soaking anything.”

Jacob shared a clear example of how critical the system became. When the dry fog system temporarily stopped operating, he switched to small household humidifiers as a backup. Due to the high air exchange, the room dried quickly and growth slowed.

Once the AKIMist®E system was restored, the response was immediate.

“The mushrooms doubled in size overnight,” he said. “That was the clearest proof of how much the system directly affects growth.”

For certain crops like maitake, which require approximately three and a half months from start to harvest, even one day without proper humidity can result in total loss.

“If humidity fails for a day, the crop is gone,” Jacob explained. “That’s months of work and investment.”

When asked about the upfront cost of a dry fog system, Jacob was direct.

“Buy now, cry now, and be happy later,” he said. “Changing the water, cleaning the system, replacing parts constantly, dealing with all the headaches that come with ultrasonic systems, that’s what everybody uses. In my opinion, it’s a huge waste of time and money. It causes inconsistencies and leads to frustrations like contamination.”

He continued, “Contamination is the number one problem every mushroom grower has. Obviously, cost is always something people have to consider, but this system, in the big picture, system-wise, is actually less expensive.”

Over time, reduced labor, fewer equipment failures, and avoided crop losses offset the initial investment.

Jacob shared several practical recommendations for growers evaluating humidification systems:

His summary for other growers was simple. If humidity is critical to your operation, invest in a solution that produces consistent results and reduces contamination risk.

Water quality also plays a role. FreeSol Farms uses a custom reverse osmosis system to supply clean, slightly acidic water, closely mimicking rainwater conditions.

“Pure water removes another variable,” Jacob said. “Anything impure increases the risk of contamination or inconsistent growth.”

FreeSol Farms focuses on producing consistent, high-quality gourmet mushrooms in a controlled indoor environment. For Jacob, precise humidification is not an accessory system. It is the core infrastructure.

“The AKIMist®E has been a game changer,” he said. “For growers who rely on consistent humidity, it’s the difference between constantly reacting to problems and actually controlling the environment.”

If you’re a mushroom cultivator exploring Dry Fog humidification, we encourage you to connect with our trusted partner and distributor, Techmark, for application-specific guidance and support.

Phone: (517) 322-0250

Email: mushroom@techmark-inc.com

Learn more: https://www.techmark-inc.com/humidification.html

Not a mushroom grower? Ikeuchi’s humidification specialists support a wide range of industries, from indoor agriculture to manufacturing and beyond. Contact our team directly to discuss your specific application and environmental requirements.