How Moisture Conditioning Reduced Cream Puff Dough Crack Defects by 80% without Over-Wetting

A simple yet effective solution—direct cooling of high-temperature blower air with a fine mist.

Paper machine in a paper mill

In paper mills, large volumes of water are consumed during production, generating wastewater containing organic matter, fiber residues, and chemical substances derived from pulp. Discharging this untreated water causes severe environmental impacts, including water pollution, making wastewater treatment facilities indispensable to mill operations.

Wastewater treatment consists of several processes—physical removal, chemical neutralization and precipitation, and biological decomposition by microorganisms. At the core of biological treatment is the aeration tank (also known as an aeration basin), where microorganisms absorb oxygen from the air and decompose organic matter to purify the wastewater.

Aeration Tank (Aeration Basin)— Microbial Decomposition and Purification of Organic Matter

In this process, it is essential to ensure a stable air supply for the microorganisms and maintain an optimal water temperature for their activity.

A paper mill was facing difficulties in maintaining stable operation of its aeration tank, which is critical to the wastewater treatment process. During summer, rising ambient temperatures caused the blower air supplied to the tank to reach nearly 70 °C, consequently increasing the water temperature inside the tank. This rise in temperature reduced microbial activity, leading to a decline in wastewater treatment efficiency.

Air Blower for Supplying Air to the Aeration Tank

Various measures—such as reinforcing ventilation in the blower room and cooling intake air with fans—were attempted, but none produced noticeable improvement. Installing an intercooler was not a viable option due to the high initial and operating costs. With no effective solution in sight, the facility engineers were left at a loss.

Amid these challenges, the customer consulted IKEUCHI to explore a method for directly cooling the blower air itself.

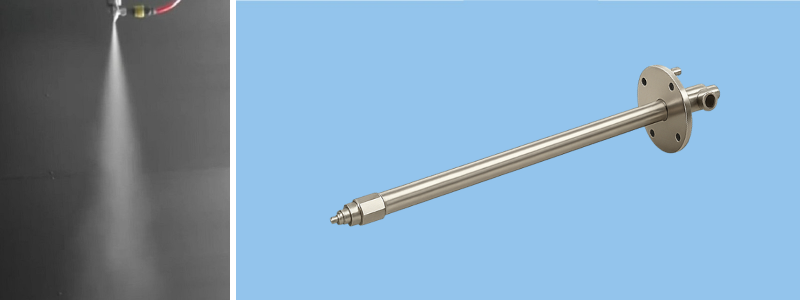

IKEUCHI proposed using the BIMJ Series air atomizing nozzle to inject fine spray into the intake duct, where the evaporation of the mist directly cools the blower air.

The nozzle was supplied in a lance-type configuration suitable for duct insertion, creating a simple yet effective cooling setup.

The blower air temperature, previously reaching 70 °C, was reduced to as low as 35 °C—within the optimal range of 20 to 35 °C for microbial activity—creating an ideal environment for stable biological treatment.

Our sales engineer surveyed the site and recommended installing the nozzle at a position where complete evaporation could occur, based on the available straight length of the duct. As a result, the sprayed water almost completely evaporated, with minimal condensate observed.

IKEUCHI’s spray nozzles continue to help maintain proper water temperature and an optimal environment for microbial activity in the aeration tank, contributing to the stable operation of the wastewater treatment system.