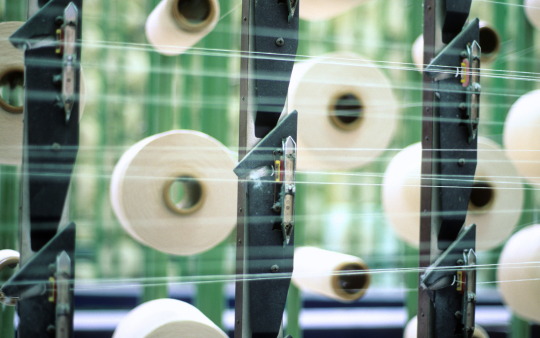

Keeping Fabrics Clean and Smooth: How Dry Fog Humidification Solves Static and Dust Issues in Textile Manufacturing

Few things are more frustrating for a textile plant manager than stopping production to fix defects that could have been prevented. Broken yarns, static clinging to fibers, uneven dyeing, and rework that consumes hours of labor can derail even the most carefully planned schedules. Often the culprit is not poor machinery or operator error, but the air itself. Inconsistent humidity can quietly wreak havoc on fibers and processes, and without precise control, these problems repeat day after day. Dry fog humidification offers a reliable way to stabilize humidity, reduce defects, and keep production running smoothly.

Textile processes are highly sensitive to the moisture content in the air. When humidity drops too low, fibers become brittle, making yarns prone to breakage during weaving or knitting. Static electricity builds up, causing fibers to cling to machinery or each other, slowing production and increasing the likelihood of machine jams. In dyeing and finishing, low humidity can cause uneven color absorption and blotchy patterns, while excess moisture can lead to fabric swelling, curling, or streaking during drying.

These defects do not just impact product quality, they also affect operational efficiency. Every yarn break or re-dye cycle interrupts production, increases labor costs, and reduces throughput. Even minor variations in fabric quality can trigger rework or scrap, translating into wasted material and lost revenue for the plant.

Dry fog systems introduce ultra-fine mist into the air, stabilizing relative humidity throughout the manufacturing space without wetting fibers or machinery. This precision control helps prevent static buildup, yarn breakage, and uneven dyeing. Unlike traditional humidifiers that can over-saturate specific areas or require constant monitoring, dry fog provides consistent, uniform humidity across the production floor.

Because the mist is so fine, it evaporates quickly and evenly, maintaining optimal conditions even in winter when indoor air is especially dry. Plants using dry fog systems experience fewer interruptions, reduced rework, and improved first-pass yield. These systems are low maintenance and energy-efficient, making them suitable for both small workshops and large-scale mills.

Stable humidity affects more than just product quality. Consistent environmental control can extend the lifespan of fibers and machinery by reducing wear caused by static and brittleness. Production staff can work in a more comfortable environment, which can improve focus and reduce errors. Energy costs are often lower because dry fog systems do not rely on excessive heating or cooling to maintain conditions. The combination of quality improvements and operational stability makes dry fog a smart investment for textile manufacturers looking to optimize efficiency and reduce waste.

Textile manufacturers who struggle with defects and inefficiencies can benefit from the precision, reliability, and low-maintenance advantages of dry fog humidification. By stabilizing humidity across the production area, plants can protect fibers, improve product quality, and maximize operational efficiency. Ikeuchi’s dry fog systems provide a modern solution that supports both traditional and contemporary textile processes while helping managers keep production lines running smoothly.