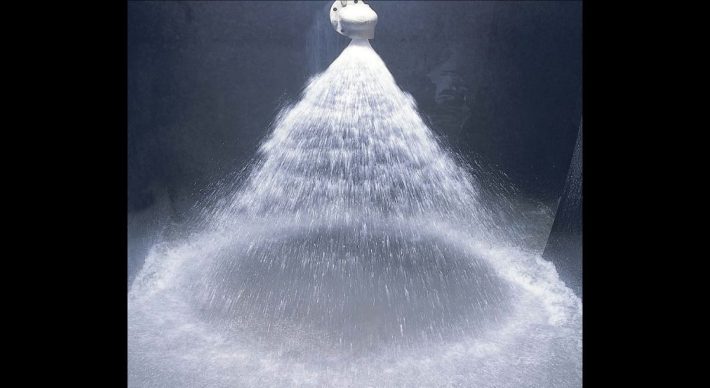

Hollow Cone Spray Nozzles AAP

Hydraulic hollow cone spray nozzles, featuring a tangential des…

Hollow Cone Spray Nozzles (Alumina Ceramic)

Hydraulic hollow cone spray nozzles, featuring a tangential design with the spraying axis at a 90˚ angle from the nozzle inlet, are made of alumina ceramic with excellent wear resistance and produce relatively fine droplets.

| Liquid Inlet Thread Size | R1/2, R3/4, R1, R1*1/2, R2, R2*1/2, R3 *1 |

|---|---|

| Main Material | 92% Alumina |

| Spray Droplet Measuring Method | Immersion sampling method |

| Mean Droplet Diameter | 580–1,800 μm |

| Standard Pressure | 0.2 MPa |

| Spray Capacity (Flow-rate) at Standard Pressure | 14.0–600 L/min |

| Spray Angle at Standard Pressure | 80º, 85º |

Materials: Click here for full material descriptions, including chemical and heat resistance.

*1) The listed sizes refer to the nozzle's male threads. When sold with a stainless steel socket, the actual liquid inlet size will be Rc (female thread). The socket turns the male nozzle thread into a female connection, preventing damage to the delicate alumina threads.

• Hollow cone spray nozzle made of alumina ceramic having excellent wear-resistance.

• Spray pattern is stable both at low and high pressure.

• Hollow cone spray nozzle with relatively fine atomization.

• No-whirler design minimizes clogging.

• Spraying axis 90゚ from the axis of the nozzle inlet.

Hydraulic hollow cone spray nozzles, featuring a tangential des…

Hydraulic hollow cone spray nozzles, featuring a tangential des…

Hydraulic hollow cone spray nozzles, combining two TAAs designe…