Spray Nozzles for Food and Beverage Processing | 10 Case Studies (Part 2)

IKEUCHI’s spray nozzles are used in many different processes and for so many different applications, such as cleaning, spraying, moisture conditioning, disinfection, humidification, and air blowing; they have become an essential part in food & beverage factories.

This diversity of applications, from general to specific uses, is also the reason it is very difficult to choose the best nozzle for a particular application, while using the right nozzle for an application can lead to automation, cost reduction, improvement in productivity and quality.

While these carefully selected examples compiled as “10 Case Studies on Spray Nozzle Applications” might not reflect everybody’s specific needs, they will hopefully give an insight into the possibilities available to solve those needs.

This first article will discuss three case studies dealing with greasing molds, applying glaze, and disinfecting areas in baking factories.

The Problem:

A baking factory was greasing bread molds by hand. Greasing thousands of the molds moving along a conveyor belt each day was taking away time and manpower to deal with other tasks. IKEUCHI was asked if there was a better solution.

The Solution:

It was proposed to use a spray nozzle unit to automate the greasing process.

Initially the customer was concerned about excess oil application to the molds and more frequent maintenance due to nozzle clogging. These concerns were addressed by selecting clog-resistant pneumatic nozzles that could apply a small amount of oil and adding an automatic on-off function combined with a sensor, preventing the unit from spraying oil continuously.

The Results:

Automating the greasing process freed employees for other tasks, provided a more even application which provided consistent quality and the on-off function reduced oil consumption.

Spray nozzle used for this process:

Low Flow Rate Fine Fog Nozzles | Full Cone Spray | BIMJ Series

The Problem:

A baking factory was having trouble with the spray nozzles they used to glaze their cakes. The high air pressure that was needed to spray the glaze damaged the cake tops and the large droplet size caused uneven application and thereby defective product.

The Solution:

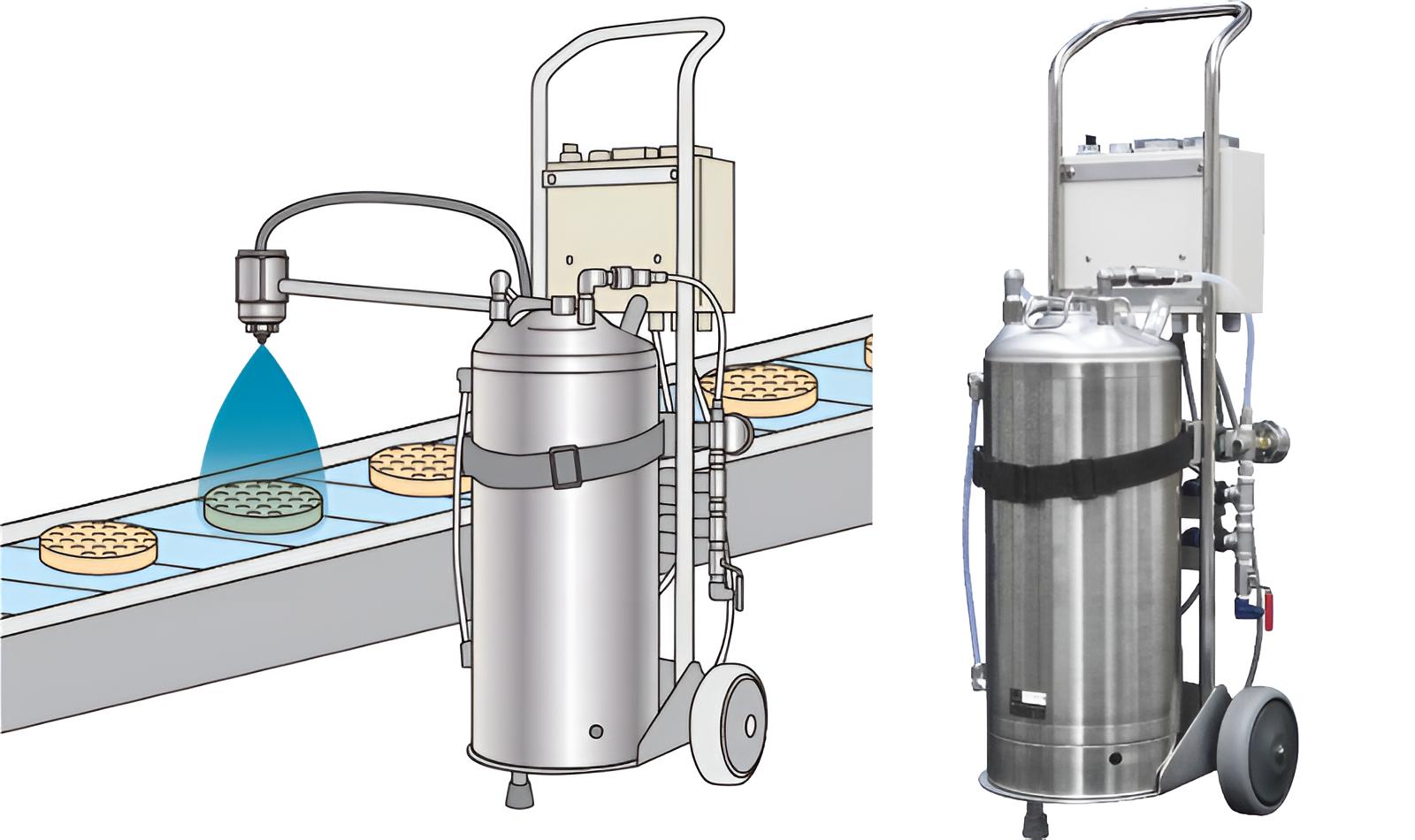

IKEUCHI proposed a spray unit equipped with a small pneumatic nozzle that uses lower air pressure.

By selecting a nozzle with a wide spray angle for wider surface coverage, the momentum of the air was further dispersed and avoided damage to the product. On top of that, the fine droplet size resulted in a soft and even application of the glaze.

The unit is a portable automatic spray device that can be used immediately and anywhere by moving it next to the production line.

The Results:

Reducing the number of defective product and reducing the time and effort wasted by having to remove the defective product from the production line saved the facility thousands of dollars a year.

Spray nozzle used for this process:

Compact Design | Low Flow Rate Fine Droplet Nozzles | Flat Spray | CBIMV Series

The Problem:

A baking factory was having problems dealing with mold in the cooling room for the baked loaves. This is the room where the hot loaves are temporarily stored until they have cooled down.

The room is cooled from a duct in the ceiling, but when a lot of fresh baked loaves come into the room, the temperature rises and makes it easy for mold to grow. The challenge was to suppress mold growth in an environment perfect for mold.

The Solution:

Spraying alcohol through spray nozzles installed in the cooling duct leading to the cooling room and using the air flow to disinfect the entire room.

The requirements were that the inside of the duct could not get wet, and that the system could operate automatically. To address them a timer control and a pneumatic nozzle spraying fine droplets with an average droplet size of 20 to 100 μm were combined to create a system that could automatically and intermittently spray.

The Result:

The system achieved indirect disinfection of the entire room without spraying alcohol directly around the bread, suppressing the mold growth. The fine fog combined with the automatic intermittent spray did not get the inside of the duct wet.

Spray nozzle used for this process:

Low Flow Rate Fine Fog Nozzles | Hollow Cone Spray | BIMK Series

Spray nozzles used in food & beverage manufacturing have a wide variety of applications, such as cleaning, spraying, humidity control, disinfection, and air blowing. This diversity of applications can make it difficult to choose the right nozzle. In order to give an insight into some of the possible solutions available, the 10 sample cases were carefully selected from our many satisfied customers and compiled as “10 Case Studies on Spray Nozzle Applications”.

This first article reviewed three cases at baking factories.

The next article will discuss three examples of greasing the conveyor belt, moisture conditioning of dough, and disinfecting the conveyor belt in confectionery manufacturing factories. Stay tuned for more articles.