Dual-Function Single Nozzle for Cleaning-In-Place (CIP) in Aseptic Filling Machines

Solutions or Products Featured

in This Case Study

At a food processing plant, waste liquid was transported by tanker trucks, with the tanks manually cleaned upon their return from waste treatment.

The cleaning process took about one hour for a smaller tanker truck and two to three hours for a larger one. A major challenge was removing the sludge-like waste liquid stuck to the bottom of the tank, which had to be loosened and cleaned to ensure smooth discharge.

The customer approached us with an urgent request to automate the labor-intensive tank cleaning process and achieve greater efficiency.

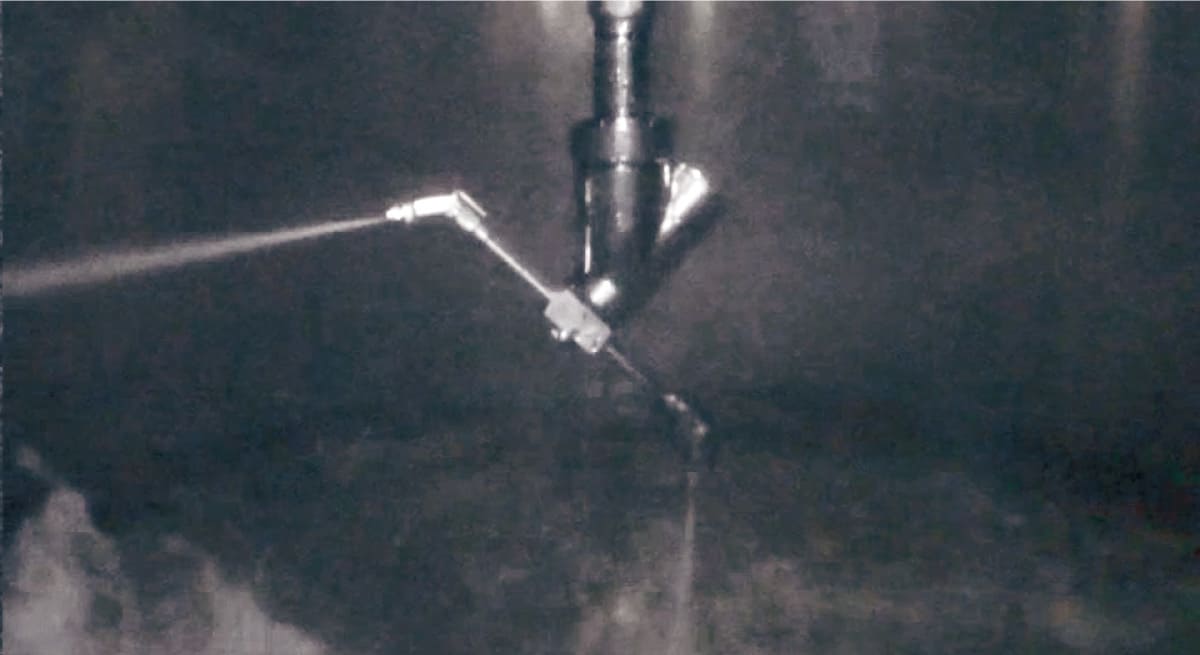

We promptly selected the JA3-D180, a 3D rotating tank cleaning nozzle, which thoroughly covers and cleans the lower half of the tank. Its powerful, solid water streams effectively loosen and remove sludge-like waste liquid stuck to the tank bottom, ensuring thorough cleaning and smooth discharge.

To ensure the customer’s confidence in our solution, we proposed on-site testing using a demonstration unit.

With the nozzle installed, testing confirmed that the adhered waste liquid could be efficiently loosened, cleaned, and discharged. The system now enables automatic cleaning without manual intervention, delivering both significant labor savings and complete automation.

This has provided an effective solution to labor shortages, allowing personnel and time previously spent on cleaning operations to be reallocated to other tasks.