Technical Library

- HOME

- Technical Library

- Optimizing Gas Cooling Nozzles for Enhanced Maintainability at Waste Incineration Plants

Optimizing Gas Cooling Nozzles for Enhanced Maintainability at Waste Incineration Plants

Solutions or Products Featured

in This Case Study

Key Reasons for Implementation

- Integrating the nozzle tip and protective sleeve enables simultaneous replacement during regular nozzle maintenance, streamlining overall maintainability.

- Eliminating gaps between the nozzle and sleeve enhances protective performance for both the nozzle and the piping.

- Not sure which product is right for you?

- Curious about the total cost?

- Wondering where to start?

- We’re here to help – reach out with any questions.

Challenges Faced by the Customer

An engineering company specializing in waste incineration plants faced challenges with the gas-cooling return nozzles (spillback nozzles) used for cooling exhaust gas in their cooling tower.

Recent increases in incineration heat had caused exhaust gas temperatures to rise, placing excessive strain on the system. The nozzles, subjected to these elevated temperatures, conducted heat from the nozzle tips to the piping, causing damage. Although the nozzle tips were regularly replaceable, frequent piping replacement demanded considerable time and expense.

Seeking a solution to mitigate piping damage and enhance maintenance efficiency, the customer turned to us for assistance.

Proposals from IKEUCHI

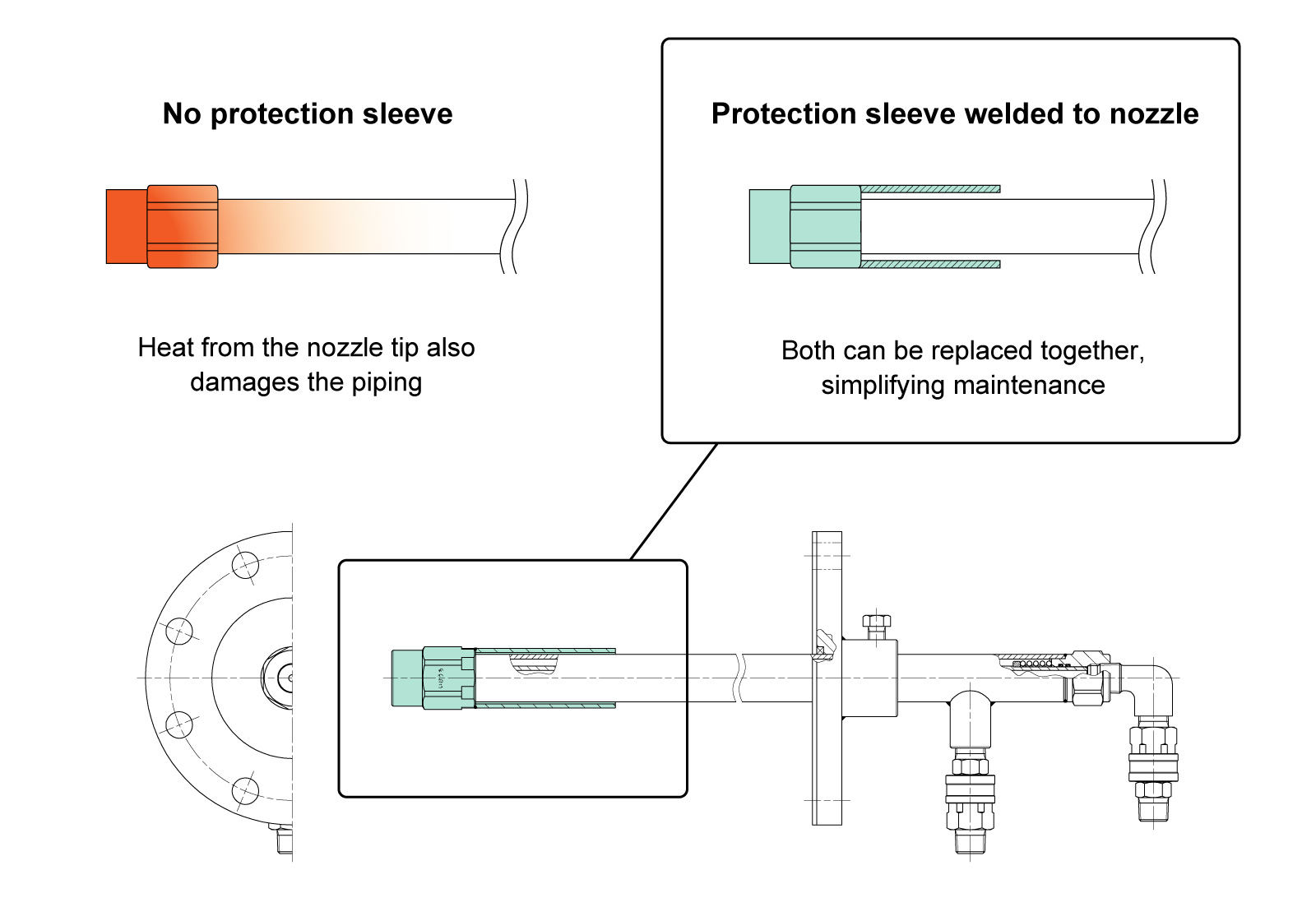

Initially, we considered covering the nozzle section with a sleeve to reduce heat damage to the nozzle piping. However, this approach would have required managing the replacement schedule for both the nozzle and the sleeve, leading to complex maintenance procedures and a risk of oversight in the field.

To address this, we proposed a unit design where the nozzle section and sleeve are welded together, allowing both to be replaced simultaneously. This structure eliminates gaps between the nozzle and sleeve, further enhancing the protective performance of the nozzle piping.

Benefits Achieved

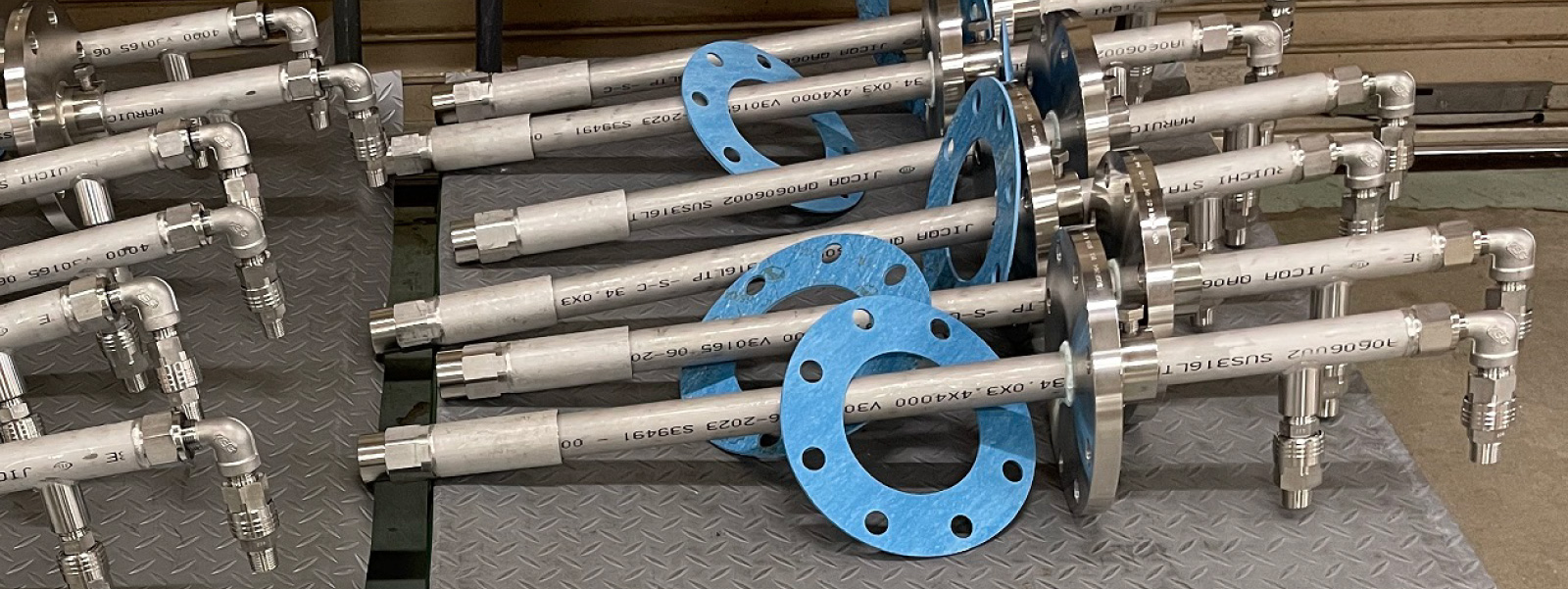

- Eliminating the need to manage separate replacement schedules for the nozzle section and sleeve has significantly enhanced maintainability. This solution has received high praise on-site, prompting requests for similar specifications in other projects.

- The nozzle piping is now effectively protected, enabling stable operations at the waste incineration facility.