Lubricant Spray Optimization Prevents Line Stops and Reduces Usage by 50% in Beverage Factory

Solutions or Products Featured

in This Case Study

Press forming is a manufacturing process in which sheet metal (or other workpieces/blanks) is pressed against a die to form the desired shape. It is widely used across industries such as automotive and electrical component production.

The primary purposes of applying lubricating oil to metal blanks (workpieces) in press forming are as follows:

1. Reducing Friction

Lubricating oil forms an oil film between the die and the workpiece, reducing friction. This allows smoother metal forming and contributes to improved processing accuracy.

2. Protecting Dies and Related Components

Proper lubrication protects dies and associated components from wear and overheating, contributing to extended die life.

3. Assisting in Forming Difficult-to-Process Areas

In processes involving large deformation, such as deep drawing or complex shaping, lubricating oil reduces forming loads and helps prevent cracking or wrinkling of the workpiece.

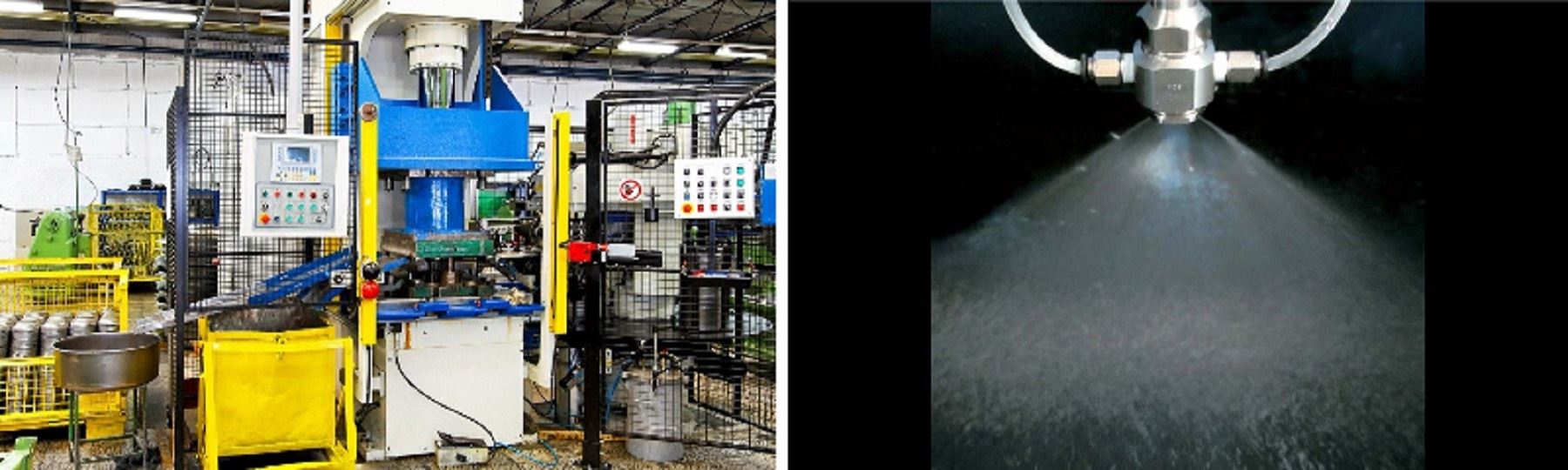

A press machine manufacturer developing a new model consulted us on the selection of lubrication nozzles to be used in their machine.

They wanted to avoid the roller method that applies lubricant by direct contact with the workpiece, as it tends to wear quickly, and instead aimed to adopt a non-contact spray nozzle system.

However, the two nozzle types they were considering each had their own advantages and disadvantages, leaving them uncertain about the final choice.

First, pneumatic (twin-fluid) nozzles, also known as air atomizing spray nozzles, generate a fine mist by mixing compressed air with the liquid, thereby reducing lubricant consumption. However, because of the air mixing, the mist tends to disperse easily and contaminate the surrounding area.

In addition, the use of compressed air entails ongoing operating costs.

On the other hand, hydraulic (single-fluid) nozzles that spray by pressurizing the liquid are prone to dripping, resulting in excessive application and increased overall consumption of the lubricant.

The size of the blanks (workpieces) to be press-formed varies by production lot, ranging widely from 95 mm to 800 mm. Larger workpieces require multiple nozzles installed across the line width to ensure full coverage. Conversely, for smaller workpieces, the customer wanted to minimize waste by reducing the number of active nozzles and applying lubricant only to the necessary area.

We selected hydraulic spray nozzles that minimize mist dispersion and do not require compressed air for spraying, thereby reducing operating costs.

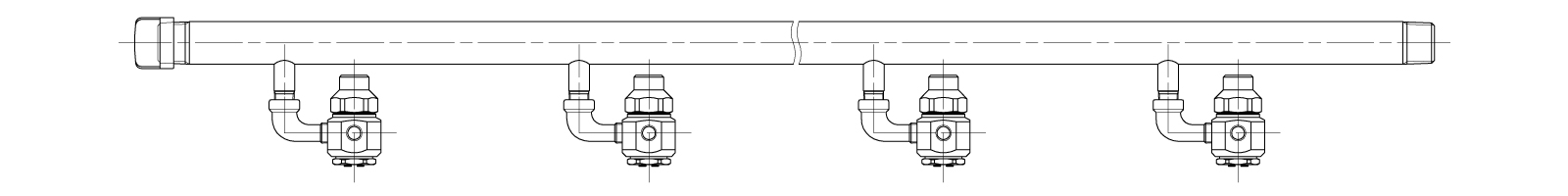

Then, from among flat spray pattern nozzles with a wide spray width, we proposed the anti-drip SO-V Series, which enables responsive spray on/off control via pilot air. This feature prevented dripping and excessive application, ensuring precise lubrication.

Furthermore, by choosing the model with the lowest flow rate in the series, we reduced the spray volume to just 2 cc/sec per nozzle.

By mounting five SO-V nozzles on a header, the system can cover blanks (workpieces) up to 800 mm in width. For smaller workpieces, deactivating unneeded nozzles allows lubrication only over the required area, helping to reduce fluid consumption.

Note: The wavy lines indicate omitted sections. In practice, five nozzles are installed on the header.

Spray on/off control in operation

All of the customer’s requirements were successfully met, leading to installation in the next-generation press machine. Moreover, we have continued to receive repeat orders when improving current models.

IKEUCHI’s nozzles continue to contribute to lubricant savings and efficient application today.

Pulse spraying with the SO-VV, the sister model of the SO-V Series