[PDF] Dry Fog Humidification Solutions for Printing: 8 Case Studies

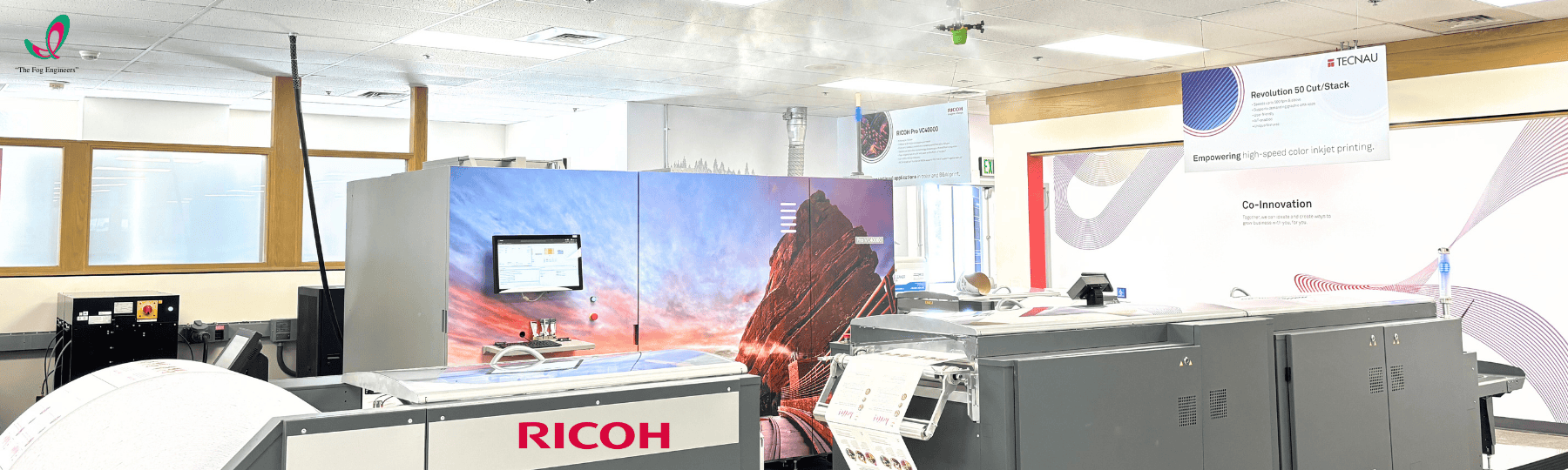

The Ricoh Customer Experience Center (CEC) is a flagship facility where cutting-edge print technology meets rigorous performance standards. As part of their ongoing commitment to quality, the CEC continually monitors environmental factors like humidity that impact print performance.

By 2021, the CEC’s existing humidification system, designed by a local integrator, was no longer meeting evolving production demands. Despite best efforts from the team, the system struggled to consistently maintain the 42% RH target, which led to occasional issues with static buildup, ink adhesion, and paper handling. As production requirements increased, so did the need for a more robust, reliable solution.

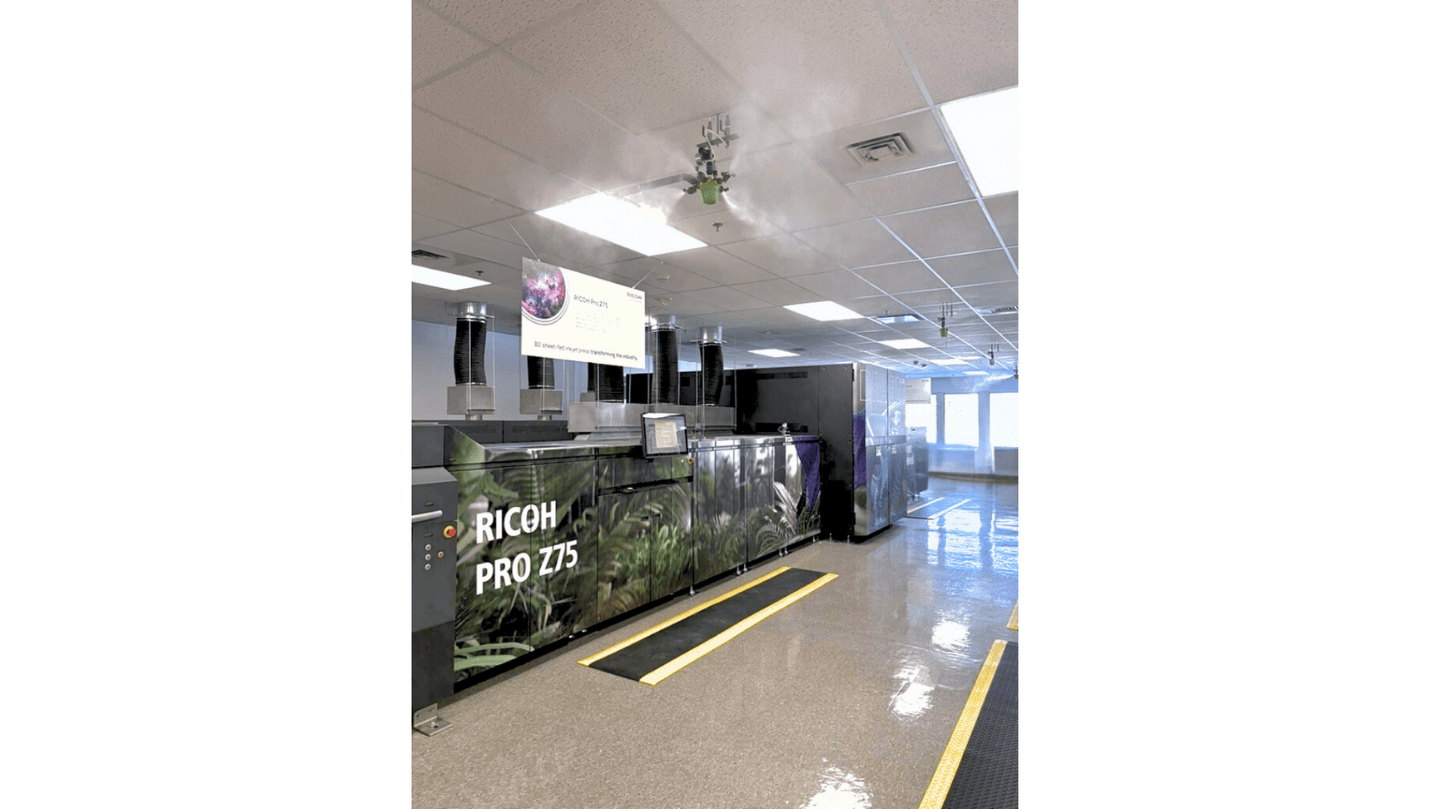

Recognizing the need for enhanced environmental control and dependable support, Ricoh selected Ikeuchi’s advanced Dry Fog humidification system. In 2021, 13 AE units were installed at the CEC, marking the beginning of a transformational upgrade.

The installation process was described as “smooth, inexpensive, and turnkey.” The Ikeuchi system integrated seamlessly with CEC operations, ensuring minimal disruption during the transition.

Within two phases of deployment, the CEC achieved a dramatic improvement in print consistency. Humidity-related error rates fell from around 72% to below 1.5%, surpassing Ricoh’s stringent performance targets. Print anomalies tied to static and ink performance were effectively eliminated.

The CEC team saw a significant reduction in preventative maintenance needs, with the interval between service intervention related to lack of consistent humidity considerably extended. Importantly, the Ikeuchi system has required virtually no corrective maintenance since installation.

Even after the CEC increased its air exchange rate from 1.5x/hour to 8x/hour in 2024, the Ikeuchi system maintained humidity within 2% of target, a critical factor in maintaining optimal print quality.

The sales team has been more likely to present first-pass print samples to customers, reflecting the improvements in reliability and consistency.

Beyond the technical results, Ricoh has valued Ikeuchi’s responsive support and willingness to provide extended training. This partnership approach has been an unexpected benefit that has added significant value to the relationship.

Looking ahead, the CEC team has expressed interest in exploring portable Ikeuchi systems for media qualification and performance testing across its labs, pointing to continued innovation together.

Would Ricoh recommend Ikeuchi’s humidification system to other sites or customers?

Absolutely.

“We know it’s the most effective way to manage RH at a low cost.”

Through a shared commitment to excellence, Ikeuchi has helped the Ricoh CEC elevate environmental control and achieve world-class print quality, reinforcing Ricoh’s position as a leader in the industry.