Energy Efficiency with Humidification | Industrial Energy Savings | Sustainable Industrial Practices | Optimize Energy Use

One of the main ways to classify commercial humidifiers is their humidification method. With so many options, it can be hard to identify the right one for you. Installation methods can also be a great factor in your decision as facility layouts may be limiting. Here, we will explore these methods of humidification & installation, and how they differ.

This method diffuses moisture through a filter soaked in water by blowing air onto it. This is a great option if your goal is to keep power consumption low and eliminate any risk of fire, as it does not require any heating elements. However, with the lack of heat, bacteria are likely to grow on the filter so regular cleaning and maintenance is required. Another downside with the evaporation method is that it has a lower capacity for humidification, so this is not suitable if you’re looking for higher levels of humidity.

This method humidifies by evaporating water in the tank. The evaporation is caused by heating the water to a high temperature, which is also effective in suppressing the growth of bacteria. Additionally, its high humidification capacity and resistance to the surrounding environment make it advantageous. Be aware that running costs are higher and high-temperature steam can be hazardous.

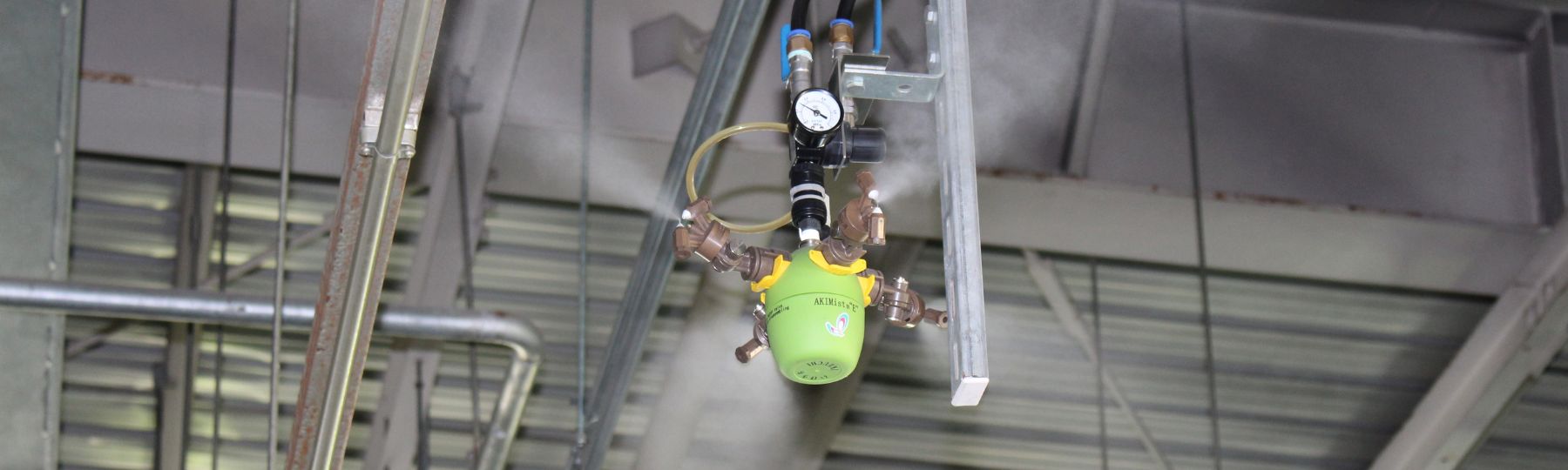

This method takes two different forms, ultrasonic method and high-pressure spray method. Both have low power consumption and high humidification capacity. The ultrasonic method atomizes water into fine particles through ultrasonic vibration. High-pressure humidification sprays water into a mist by applying pressure to the spray nozzle. There are two types of high-pressure spray methods: Hydraulic: Sprays pressurized water with a pump. Pneumatic: Produces even finer water particles by spraying compressed water and air simultaneously. If tap water is used, it will spray the minerals contained in the water, leaving a white cast on surroundings. It is imperative to use purified water to prevent this.

This method passes water vapor through a porous wall and flowing air around the wall allows for humidity. Since the porous wall only allows water to pass through, it performs clean (no bacteria) humidification without heating which keeps running costs low. However, regular maintenance is required.

This method is a combination of the humidification methods to utilize their respective advantages. For example, combining the evaporation & steam method can suppress bacterial growth while reducing power consumption. Since the hybrid method has multiple functions, its structure may become complex, and the unit price may become high. Also, since it may not operate in the steam method all the time, its effectiveness in suppressing bacterial growth may be weaker compared to the steam method alone.

Fixed installations include floor-standing types and ceiling-mounted types, and their key characteristics are their large size and high humidification capacity. Though installation work is required, it will save some time in the long run by performing water supply and drainage. The downside is, once installed, it cannot be moved easily and it is costly, so the decision has to be made with careful consideration.

Portable units do not require installation work and can be introduced easily; their casters also make them mobile. This is optimal for spot/target humidification, easy storage if humidification isn’t always needed, and frequent layout changes within facility. Since portable units are likely installed near the line, there is a possibility that it interferes with productivity of workers by taking up space.

Have an idea of the space that requires humidification as the unit price, operating cost, and energy consumptions is affected by the capacity of the humidifier.

Often times, desired humidity levels vary depending on industry and the materials being handled. This requires delicate control as too little, and excessive humidity can cause damage. Systems with an automatic control function is ideal.

Water is the core of humidification so it’s no surprise that water supply is an important factor. To save from the trouble of manual water supply, it is ideal to have a system with an automatic water supply function. Also, a filtration system is crucial to prevent minerals and impurities from being sprayed.

The main costs for operating commercial humidifiers are electricity and maintenance. Electricity use varies depending on the humidification method. Generally, the steam method is the most costly. Maintenance costs can come in the form of time from workers or requiring a specialist to come. These should be considered as running costs can add up over time where it could have been avoided with an initial investment on a higher unit price humidifier.

In addition to the running cost associated with maintenance, the original function of the humidification system can be compromised without proper care. Common upkeep has to do with filter replacements, manual water supply, nozzle cleaning, etc.

For portable humidifiers, be sure to confirm power supply. Some can utilize the common single-phase 100V, while others may require a three-phase 200V power supply.

Choosing the right industrial humidifier can be difficult without being able to test it. Renting can be beneficial for these instances but the types of humidifiers available for rental are limited.

Running through this list, you may have noticed that there’s a downside to almost every option. Ikeuchi has a humidification system that has considered all the pros and cons of these methods to create the ultimate solution: Dry Fog Humidifier AirAKI®. This humidifier uses water and air to spray a fine mist, also known as dry fog, allowing for energy efficient and precise humidity control. This system is highly adaptable as you can customize it to a fixed or portable installation with: Hanging Down Kit, Wall Mount Kit, or AE-T Set. Dry fog allows for precise spot humidification without the worry of wetting equipment or materials and it is a cooling mist so it eliminates the dangers associated with high-temperature humidity. Fill out our inquiry form or email us at sales@ikeuchi.us for a free consultation with our Fog Engineers.