Interview: IKEUCHI ORGANIC | Humidity Control Solved Floor Wetting & Weaving Issues in Towel Production

Solutions or Products Featured

in This Case Study

In the spinning industry, maintaining a specific moisture level in cotton is a traditional practice to ensure yarn quality. The price of yarn depends on both its quality and weight, which significantly impacts profitability. The acceptable moisture range for the yarn is defined in the industry standard.

“IKEUCHI’s humidifier AKIMist® was introduced to me by an acquaintance who was also working at a spinning company. We were considering the implementation of humidifiers for the moisture conditioning process before the outgoing packing, where it is essential to achieve uniform moisture conditioning deep inside the cones. The ability of AKIMist® to spray a fine fog that does not wet objects convinced me of its great potential.”

I immediately requested a demonstration and, upon experiencing the non-wetting “Dry Fog”*1 sprayed from AKIMist®, became convinced of its humidification effectiveness.

The owner had also observed AKIMist® in use at another company and, reassured by its proven performance, we decided to proceed with the implementation right away.

Moisture Conditioning with AKIMist®

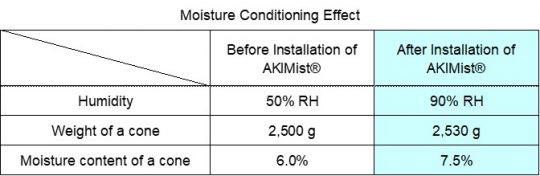

The implementation has been very successful. By spraying the Dry Fog within a simple vinyl partition and leaving the cones for five hours, we achieved the target moisture content.

The fog not only covers the surface of the cones but also penetrates deep inside, providing uniform and efficient humidification without wetting the floor or surrounding equipment.

With consistent moisture conditioning of the yarn, we anticipate an annual revenue increase of US$150K. The installation cost of the system has been about US$10K*2. Given its low running costs, the system offers excellent cost-effectiveness.

The primary benefit is that by maintaining the yarn at the proper moisture content, it becomes less prone to breaking, leading to an improvement in quality. This is expected to enhance productivity and the final product quality in our clients’ subsequent processes, thereby increasing customer satisfaction.

As a next step, we are considering moisture conditioning of materials as soon as they are received. By achieving the appropriate moisture content early on, we believe we can also improve the productivity in our spinning process.

To continue meeting our customers’ needs with fully satisfying products, we will strive to enhance quality using advanced factory conditions and equipment.

*1 Dry Fog: an ultra-fine fog with a uniform, mean droplet diameter of 50 μm or less

*2 The implementation cost varies depending on the size of a facility.

AKIMist®, which produces the ultra-fine Dry Fog, is an industrial humidifier.

The Dry Fog is also known as “non-wetting fog” because it does not contain coarse droplets, allowing it to humidify specific areas without wetting equipment or products. Additionally, the fog has a reach of over four meters, enabling a single unit to cover a wide area.

Dry Fog Humidifier AKIMist®