Basics of Spray Nozzles | Spray Impact, Pressure Resistance, Viscosity

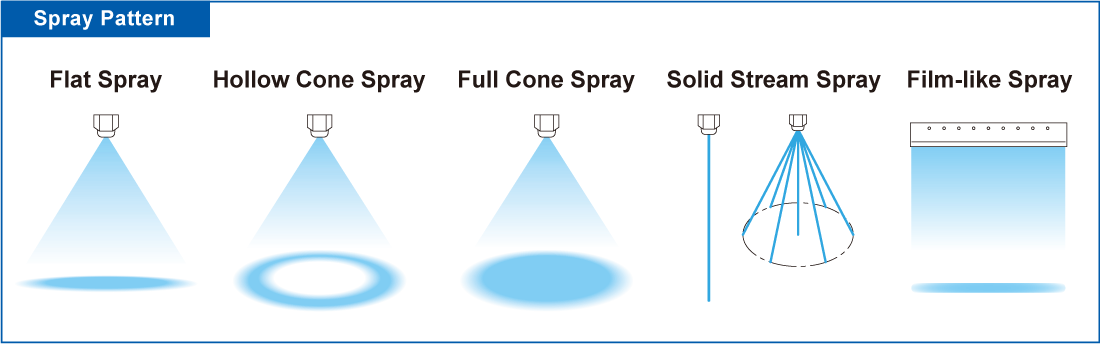

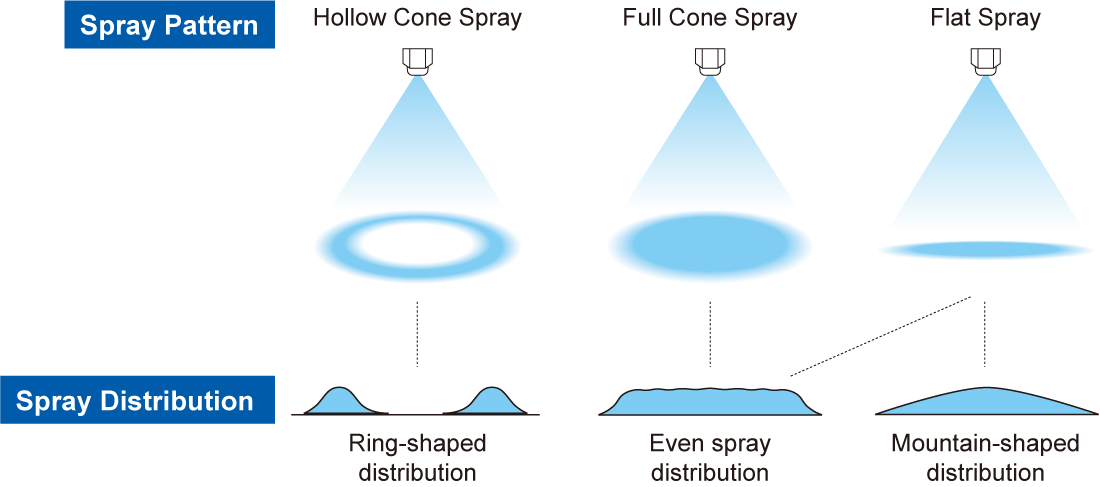

The spray pattern refers to the shape of the spray’s cross-section.

To optimize nozzle performance and its effects, it is essential to choose a spray pattern that suits each specific application.

The flat (flat fan) spray nozzles produce an inverted V-shaped spray, similar to an upside-down fan. Its main applications are cleaning, spraying, and coating.

The nozzle with a hollow cone spray pattern can produce the finest droplets of all hydraulic spray nozzles.

The full cone spray nozzles can cover a wider area with a larger amount of liquid evenly.

Both hollow cone and full cone spray patterns are ideal for applications like humidification, gas cooling, and chemical processes.

Among all spray patterns, the solid stream nozzle has the highest impact force. This makes it suitable for high-pressure pinpoint cleaning and water-jet trimming.

For additional information, visit: What is Spray Impact? | Which type of nozzle has the strongest spray impact?

Our slit nozzles feature a typical film-like spray pattern, such as the SLNH-H series (hydraulic spray nozzles) and the PSN series (pneumatic spray nozzles).

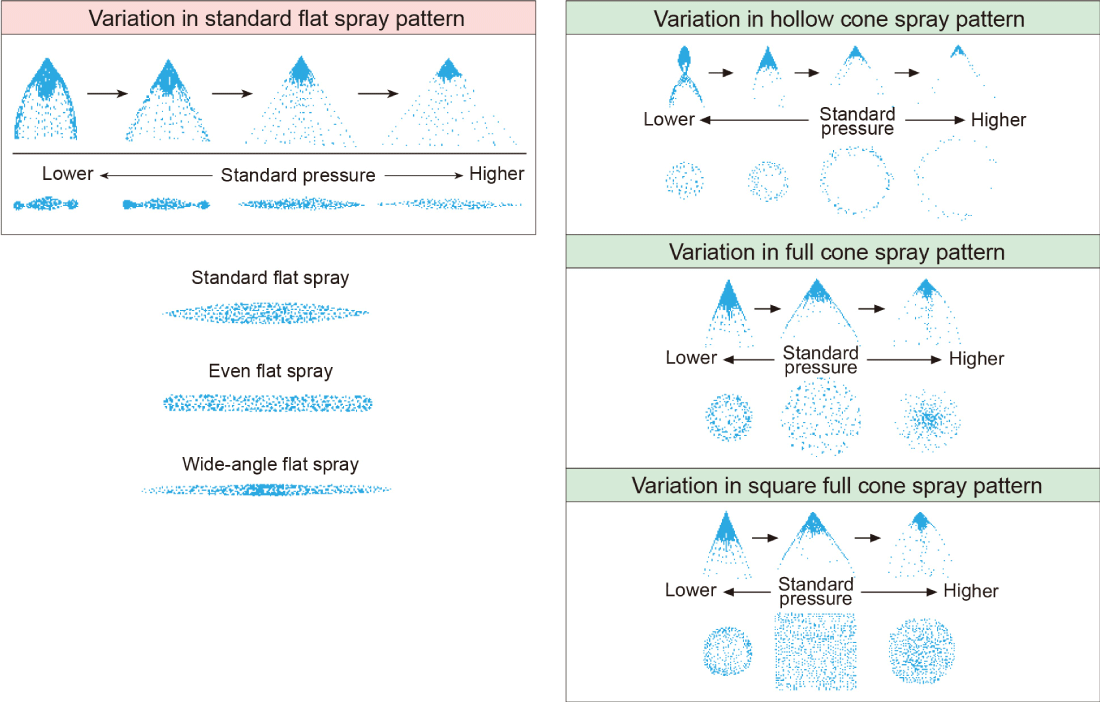

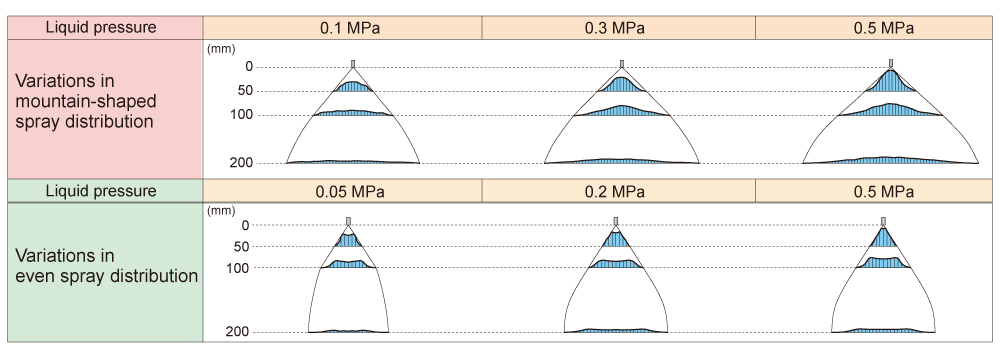

Changes in Spray Pattern According to Water Pressure

(These explanations apply to our hydraulic spray nozzles.)

The spray pattern changes as the spray pressure gradually increases from low to high.

Note: The spray patterns of pneumatic spray nozzles deform significantly as the distance from the nozzle increases.

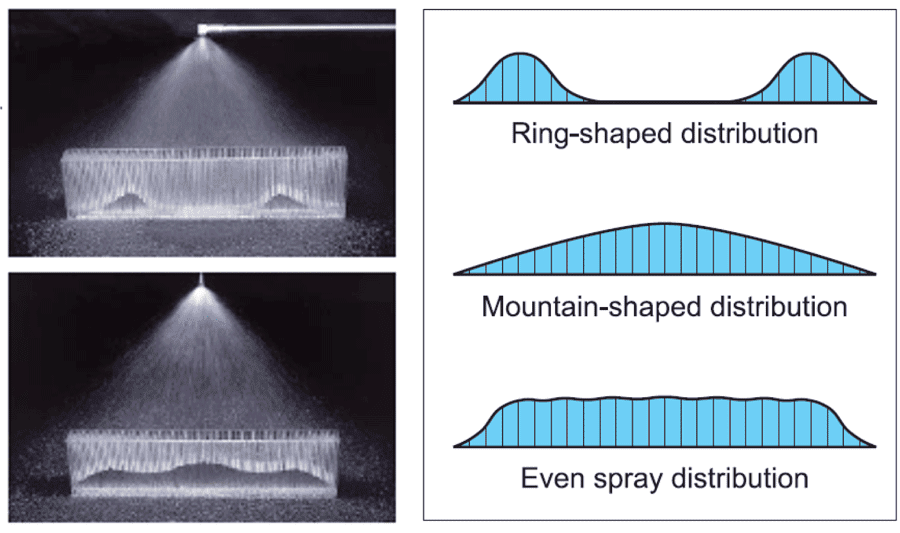

The spray distribution refers to the distribution of spray flow rate across the spray width.

There are three main types of spray flow distribution: ring-shaped, mountain-shaped, and even spray distribution.

Flat spray nozzles come in either a mountain-shaped or even spray distribution.

A mountain-shaped distribution is strongest at the center and gradually weakens toward the edges. This is useful in creating a uniform spray distribution across the entire spray width in a multi-nozzle arrangement by overlaying patterns, but the spray impact is not evenly distributed.

On the other hand, an even spray distribution, produced by an even flat spray nozzle, provides consistent spray flow and impact across the entire spray width.

This is ideal for cleaning when uniform distribution of cleaning power is needed across the spray width with a single nozzle.

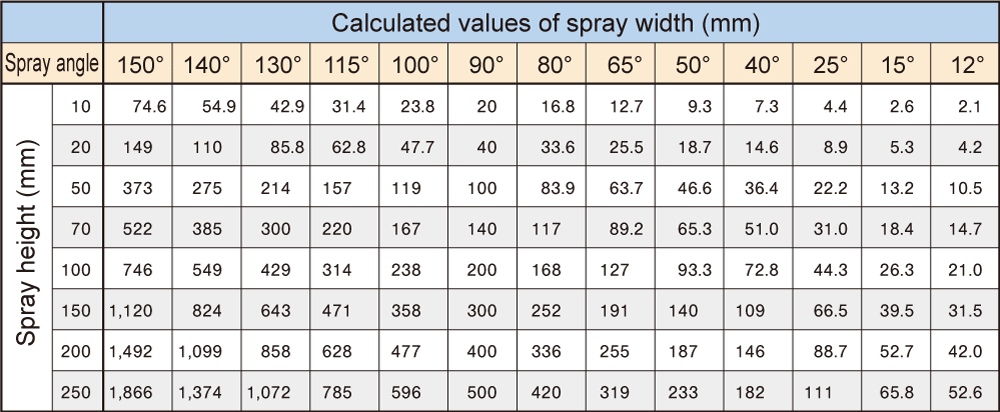

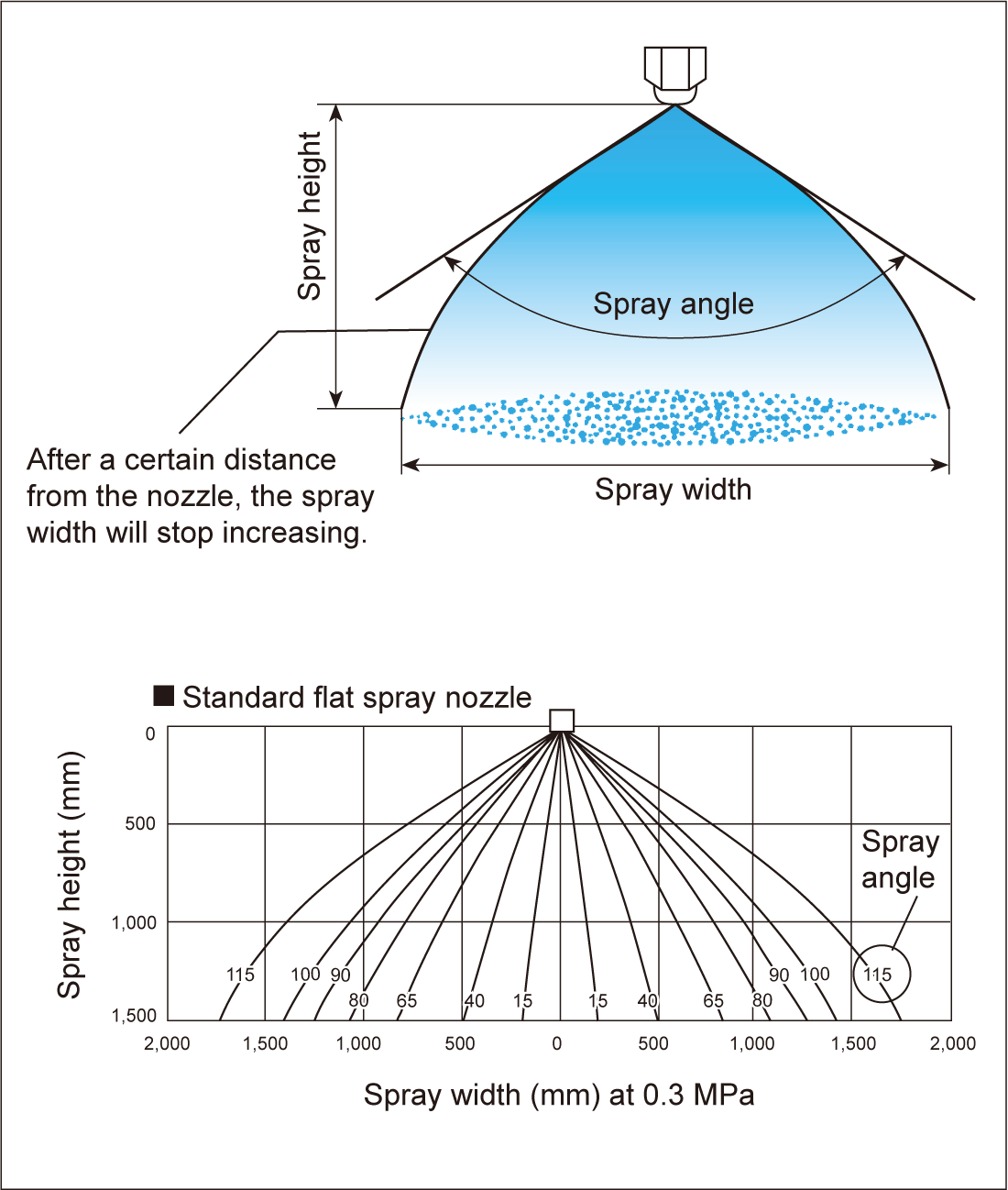

The spray angle is the angle of spray measured near the nozzle orifice.

Hydraulic Spray Nozzles

The table below shows the calculated spray width based on the spray angle.

The spray width varies depending on the spray height.

As the spray travels further from the nozzle, the droplets lose momentum, and the spray coverage width will not increase beyond a certain distance from the nozzle outlet.

Please note that the actual spray width will be smaller than the calculated values, so this should be taken into account when designing the nozzle layout.

Related FAQ: How to calculate the Spray Width based on the Spray Angle (hydraulic spray nozzles)

Pneumatic Spray Nozzles

Because pneumatic spray nozzles have a high flow velocity, the spray angle remains only near the nozzle outlet.

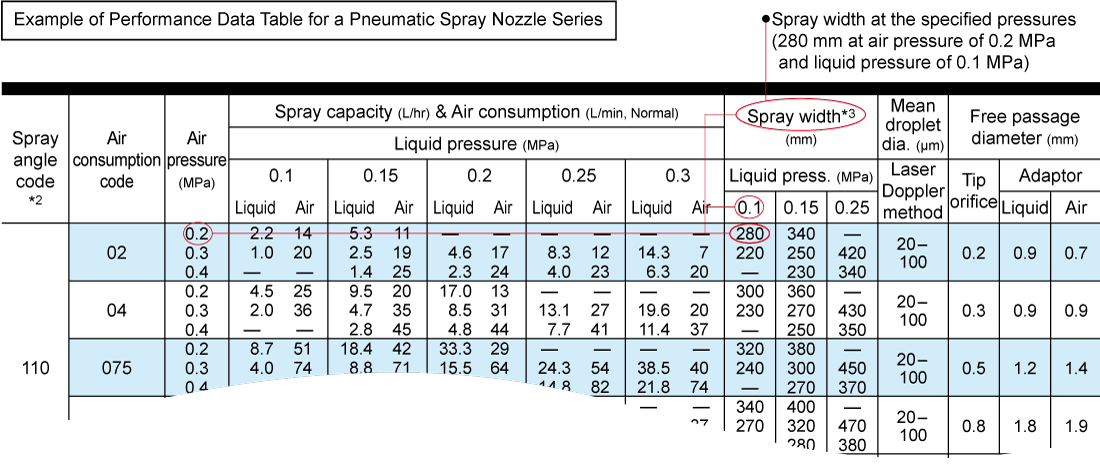

When designing a nozzle layout for pneumatic nozzles, please refer to the spray width data in the performance table of each nozzle series in the catalog.

Spray capacity refers to the volume of water that flows through the nozzle.

(In our catalogs, the spray flow rate is referred to as spray capacity.)

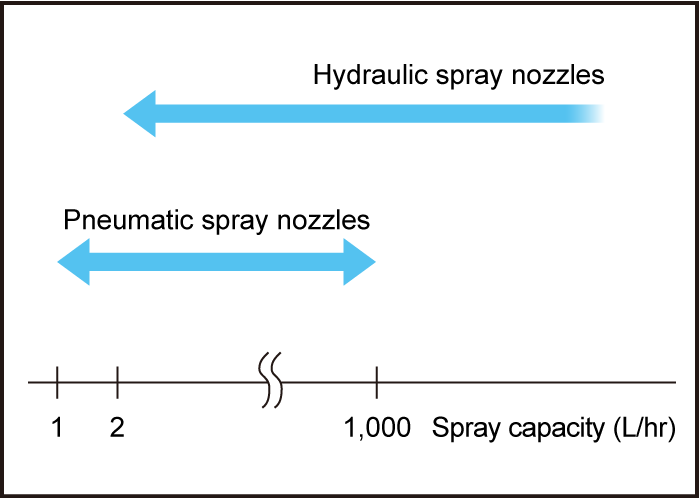

For hydraulic nozzles, spray capacity is dependent on spray pressure (liquid pressure), and the smallest capacity is approximately 2.0 L/hr (for KB and KBN Series).

For pneumatic nozzles, spray capacity is adjustable in both air and liquid pressures, allowing the spray capacity to be minimized to around 0.1 L/hr (1.7 cc/min), featuring large turn-down ratios of spray flow rate with little variation in droplet size and spray distribution.

The spray capacity values in our catalogs are based on tap water at room temperature.

Spray Capacity vs. Liquid Density

The spray capacity changes depending on the liquid density.

Generally, the spray capacity increases when the liquid density decreases or when the spray pressure increases.

Spray capacity is inversely proportional to the square root of the liquid density.

To calculate the spray capacity for a liquid with a density (γ), multiply the spray capacity value shown in the catalog by ![]() .

.