Preventing ESD Damage in SMT | 7 Benefits of Humidification (Part 1)

It is commonly said that low relative humidity increases the likelihood of static electricity generation. Is this assertion correct?

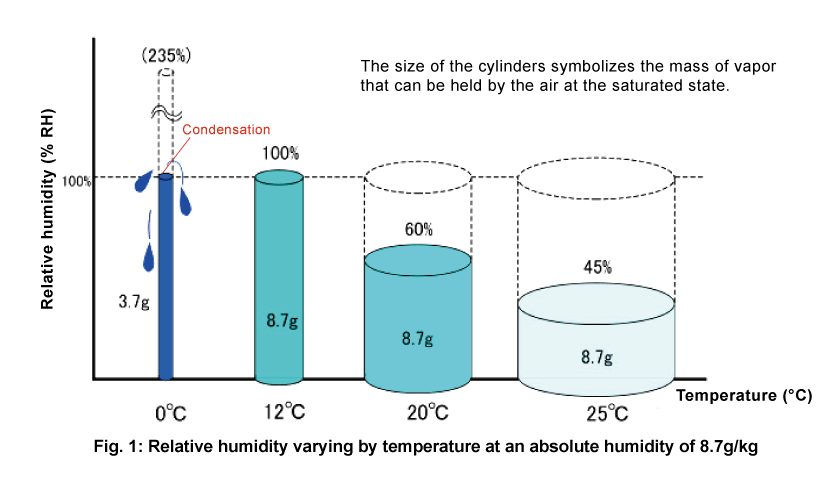

Relative humidity is defined as the ratio of the current amount of water vapor in the air to the maximum amount of water vapor that air can hold at a given temperature, expressed as a percentage (%). When people refer to “humidity,” they are typically talking about relative humidity.

Relative humidity represents the percentage of saturation of water vapor in the air, which changes with temperature. Therefore, even if the actual amount of water vapor in the air remains constant, relative humidity will vary with temperature.

On the other hand, absolute humidity is defined as the mass of water vapor contained in 1 kg of dry air (g/kg).

This measurement provides a clear indication of how much water vapor is in the air. Consequently, when absolute humidity remains constant, the value of relative humidity will change as air temperature changes, as shown in Figure 1.

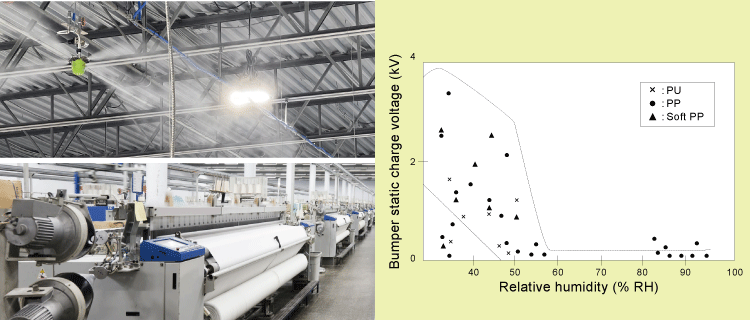

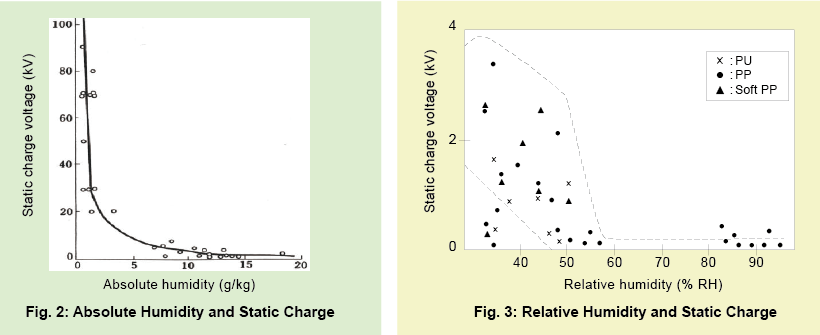

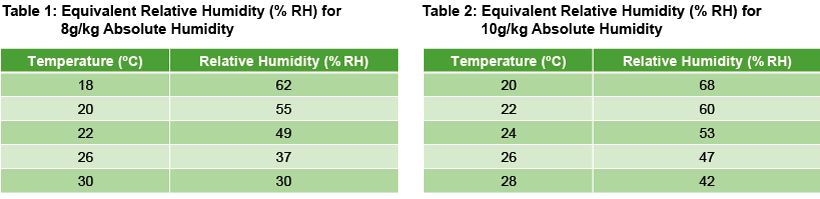

Figure 2 illustrates the relationship between static charge levels and absolute humidity measured at a moving conveyor. This graph shows that static electricity generation is reduced as absolute humidity increases. Additionally, when the temperature is held constant, the relation between static charge and relative humidity will be similar, as shown in Figure 3.

In light of these observations, IKEUCHI generally sets a target absolute humidity of 8 to 10 g/kg as a measure to mitigate static electricity. To achieve this target, it is important to maintain relative humidity levels appropriate for temperature at the manufacturing site. The corresponding target relative humidity values for each temperature are outlined in Tables below.

The concept of absolute humidity explains why static electricity is more likely to occur in dry winter conditions. Even when the relative humidity is at 50% RH during cold seasons (0ºC), the actual amount of water vapor is significantly lower compared to when the relative humidity is the same 50% RH in hot summer conditions (30ºC). To suppress static electricity, it is essential to maintain relative humidity levels appropriate for the working environment.

Related FAQ: Why is static electricity generated easily when relative humidity is low?

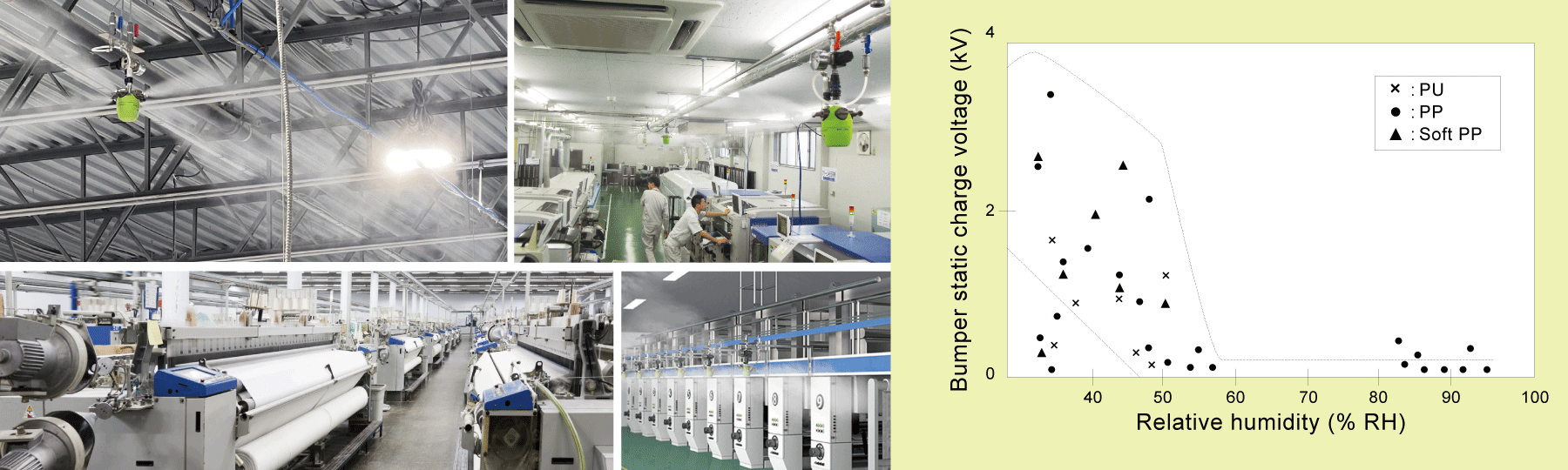

Control Humidity with Non-Wetting “Dry Fog”

The AirAKI is an advanced industrial humidification system that produces ultra-fine Dry Fog to maintain optimal humidity levels across a wide range of worksites.

It helps improve productivity and yield by preventing issues caused by dryness and static electricity.

To learn more about Dry Fog:

The Physics of Evaporation: Why Dry Fog Behaves Differently Than Misting