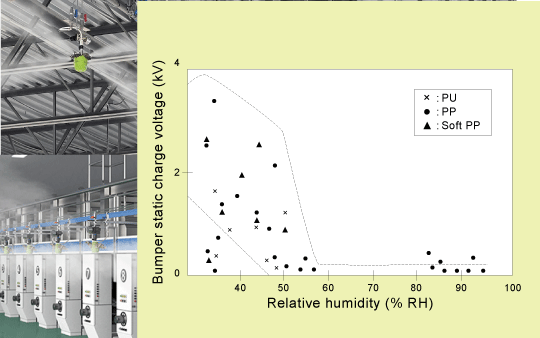

Absolute and Relative Humidity: The Relationship with Static Charge

Calibration is non-negotiable in manufacturing. From solder paste deposition to robotic movement, tight tolerances are essential for precision and yield. But while equipment is regularly tuned and verified, one critical variable often escapes that same level of scrutiny: the air.

Environmental conditions, especially relative humidity, quietly influence everything from material behavior to component safety. Yet, unlike machines with scheduled maintenance and calibration protocols, air is usually controlled by a thermostat and forgotten unless something goes wrong.

This gap between process precision and environmental stability can create a mismatch that undermines quality control.

Manufacturers invest heavily in metrology, automation, and process validation. The goal is to reduce variation and make outcomes predictable. But the same philosophy often doesn’t extend to the room itself.

HVAC systems regulate temperature, but they are not humidity control systems. Most facilities maintain acceptable air comfort, but the actual humidity levels and their fluctuations are rarely tracked with precision. Without continuous monitoring and zoned control, environmental drift becomes an invisible source of variation.

That creates risk, especially in environments where:

In each of these cases, even slight shifts in humidity can affect consistency, throughput, and rework rates. The more precise your process, the more any environmental instability will stand out.

Just like you wouldn’t run a machine without checking its alignment or output, you shouldn’t run a critical production process without understanding the environment it operates in.

Start by applying the same mindset to humidity that you would to any other variable:

Technologies like Dry Fog humidification systems can help meet these goals because they deliver humidity in fine, easily absorbed droplets that avoid wetting surfaces. This allows for consistent, uniform RH levels without interfering with equipment, product, or process.

The aim is not just to add humidity, but to calibrate it; to tune your air conditions with the same discipline used for your machines.

Precision is a system-wide discipline. It extends beyond tooling and machines to include the environment where they operate. If your process is tightly calibrated but your air is left to chance, you’re building on an unstable foundation.

To get consistent results, every part of the system must be consistent, including the part you can’t see.