Fire Protection Spray Nozzles for LNG-Fueled Vessels

Solutions or Products Featured

in This Case Study

A fire prevention equipment company was exploring fire protection measures using spray nozzles.

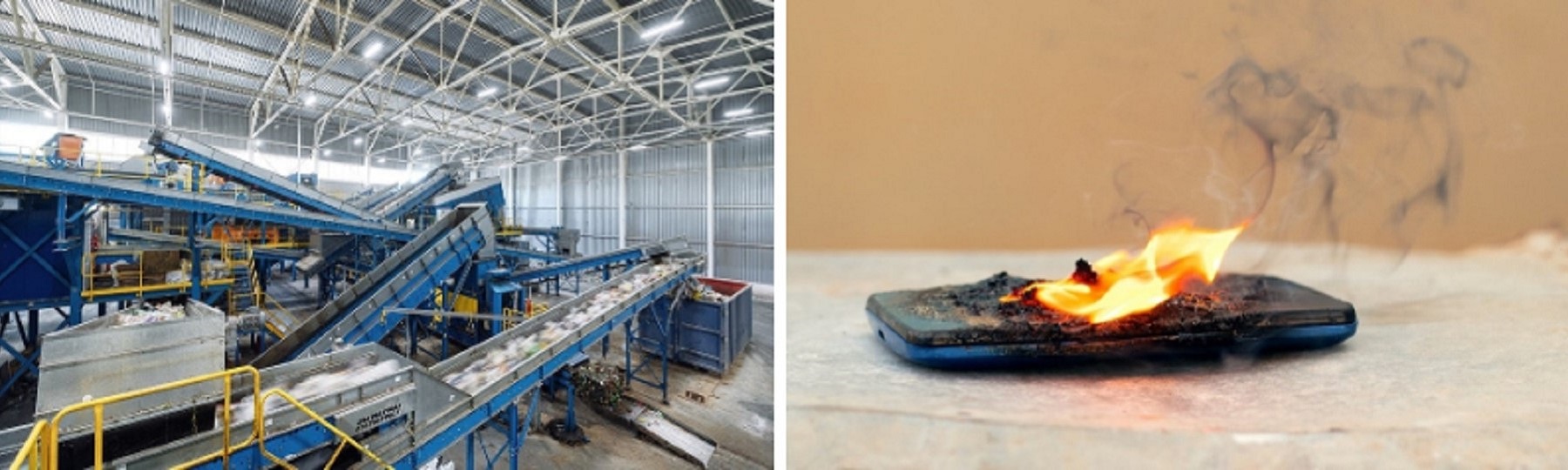

This initiative was prompted by incidents at their client’s waste processing facility, where lithium-ion batteries mixed with plastic waste ignited, causing a fire hazard during conveyor transportation to recycling processes.

They initially installed full cone spray nozzles above the conveyor line to prevent fires by spraying water. However, this caused lightweight plastic waste to scatter due to the force of the spray.

To address the scattering issue, they added curtains along the sides of the conveyor, but it introduced a new challenge: the need for regular cleaning of the curtains.

Water spraying with full cone nozzles (strong force causes plastic waste to scatter)

As a result of these challenges, they sought a more effective water spraying method to reduce fire risks and reached out to us for a solution.

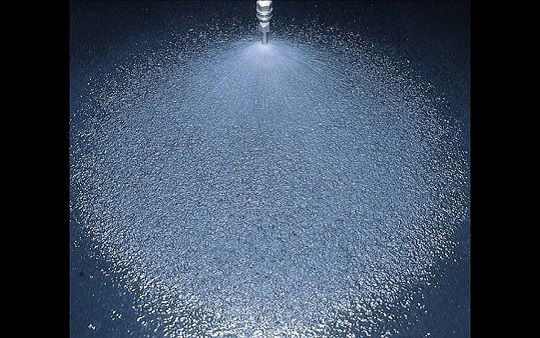

We proposed the AWVV Series spray nozzles, designed to discharge liquid fire extinguishing agents as foam.

These nozzles envelop the target area with a soft foam, allowing for effective fire prevention and suppression while also preventing the scattering of waste.

AWVV Series

It was confirmed that spraying liquid fire extinguishing agents as foam effectively reduces the scattering of waste.