Spray Nozzles Cut Sanitizer Consumption by 70% in Seafood Processing

Solutions or Products Featured

in This Case Study

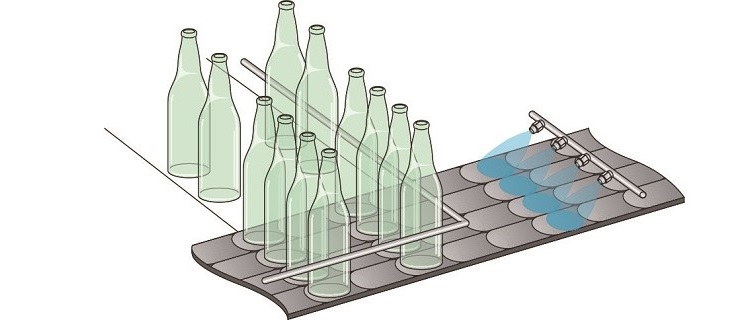

A beverage factory was facing issues with the process where spray nozzles were used to apply lubricant onto a conveyor.

This spraying process was intended to make the conveyor surface slick, allowing bottled products to move smoothly along the line.

However, in an effort to reduce lubricant consumption, the spray pressure was lowered. As a result, the liquid did not spread sufficiently across the surface, causing the bottles to lose glide and get stuck on the conveyor. This occasionally forced the production line to shut down.

IKEUCHI offered the “KB Series” nozzle, which ensures reliable surface coverage even at low pressure.

It produces the finest spray among our hydraulic nozzles while operating at a very low flow rate.

Even at a low pressure of 0.2 MPa, the lubricant spray spread at a 60° angle, enabling wider coverage with less liquid. As a result, the line no longer experienced stoppages due to insufficient lubrication.

In addition, lubricant consumption was significantly reduced compared to the previous nozzles—monthly usage was cut in half, from 1 ton to 0.5 tons.