Spray Nozzles Cut Sanitizer Consumption by 70% in Seafood Processing

Solutions or Products Featured

in This Case Study

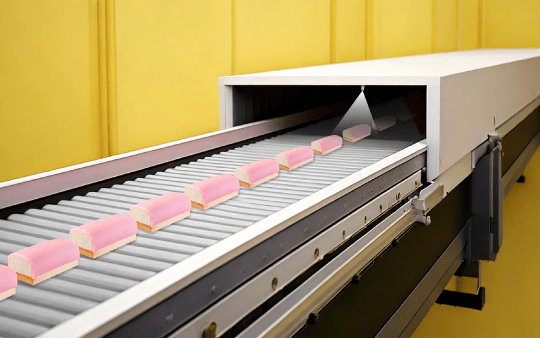

A bread factory was facing challenges with hygiene management in its bread cooling room.

This room is used to temporarily store freshly baked loaves until they cool down enough to be sliced.

Although cold air is supplied to the room through overhead ducts, the accumulation of warm bread releases heat, raising the room temperature. This creates an environment conducive to bacterial growth.

The key challenge was how to suppress bacterial development despite the unavoidable temperature rise.

Upon consultation, IKEUCHI proposed a system that utilizes nozzles to spray an alcohol-based disinfectant* within the air duct leading to the cooling room.

The disinfectant is carried by the airflow, enabling uniform disinfection throughout the space.

*Spraying may not be feasible depending on the alcohol concentration or other conditions. For details, please contact your IKEUCHI representative.

The system has successfully achieved indirect alcohol disinfection of the entire space, without spraying directly in the cooling room, effectively suppressing bacterial growth.

Furthermore, the automatic intermittent operation with fine mist did not wet the inside of the duct.

By maintaining a hygienic environment, the system continues to support the daily production of delicious bread.